Blending device for lubricating oil production

A lubricating oil and blending technology is applied in the field of blending devices for lubricating oil production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

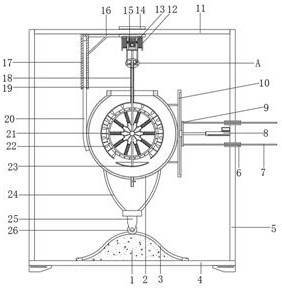

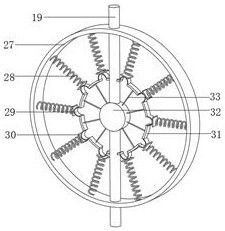

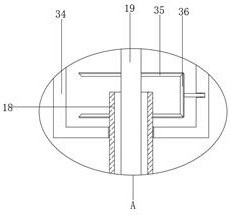

[0030] refer to Figure 1-4 , a blending device for lubricating oil production, comprising a base 4 with legs welded at the four corners of the bottom outer wall, booms 5 are vertically welded on both sides of the top outer wall of the base 4, and the top of the boom 5 is welded with the same ejector rod 11 , one side of the outer wall of the boom 5 is fixed with a push rod motor 8 by bolts, and the end of the extension rod of the push rod motor 8 is fixed with a connecting end block 9 by bolts, and the connecting end block 9 is slidably connected with a connecting end plate 10, And one side connecting the end plate 10 is welded with a blending tank 2, and the four corners of the bottom outer wall of the blending tank 2 are welded with a support frame 24, and the bottom end of the support frame 24 is welded with the same mounting block 25, and the bottom end of the mounting block 25 rotates A pulley 26 is connected, and the top outer wall of the base 4 is fixed with a corrugat...

Embodiment 2

[0041] refer to figure 1 and Figure 5 , a blending device for lubricating oil production. Compared with Embodiment 1, this embodiment also includes liquid turning plates 39 that are welded to the outer peripheral wall of the liquid-draining ring 37 and are alternately distributed with the pendulum blades 22 .

[0042] When the present invention is used: using the liquid turning plate 39 arranged on the outer wall of the liquid dialing ring 37, when the position of the mixing tank 2 and the mixing mechanism in the vertical direction changes, the stirring of the material in the vertical direction by the mixing mechanism can be further improved effect, in order to further improve the harmonization effect of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com