Surface grinding device for mechanical processing

A mechanical processing and grinding box technology, which is applied to grinding drive devices, automatic grinding control devices, metal processing equipment, etc. Control work efficiency, avoid manual clamping, and quickly fix the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

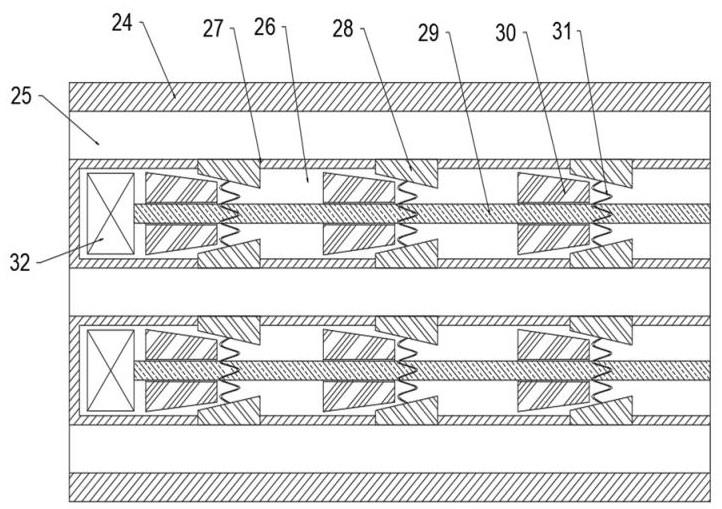

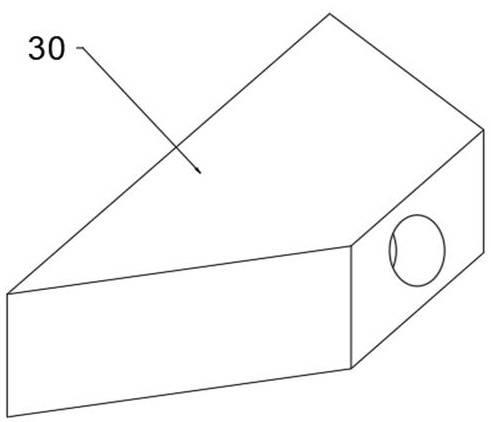

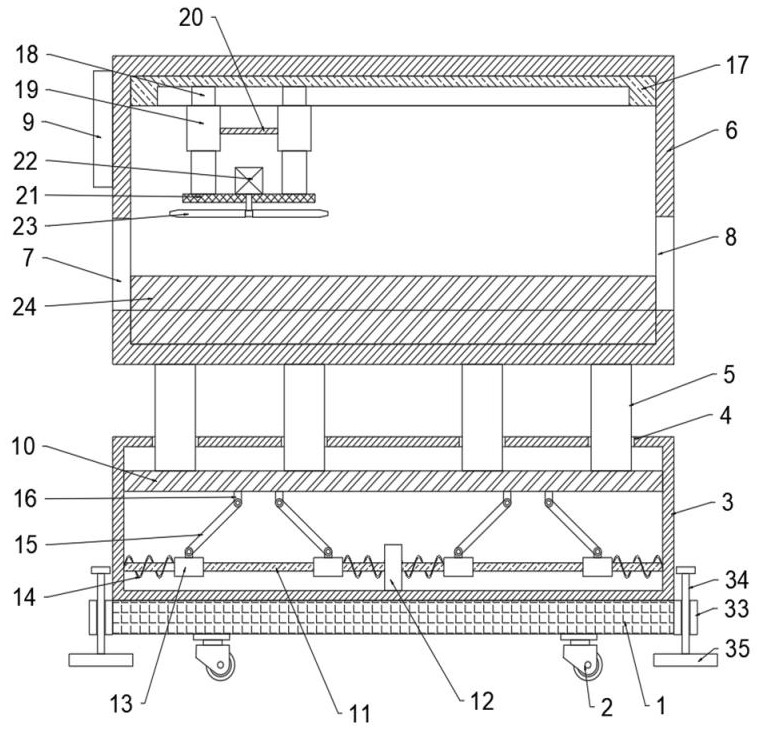

[0025] see Figure 1~3 , a surface grinding device for mechanical processing, comprising a grinding box 6, the left side of the grinding box 6 is provided with a material inlet 7, the right side of the grinding box 6 is provided with a discharge port 8, and the bottom of the grinding box 6 passes A plurality of support plates 5 are connected with the shock absorbing box 3, and the inside of the shock absorbing box 3 is provided with a shock absorbing assembly, and a slide rail 17 is installed on the top of the grinding box 6, and two electric slide rails are slidably connected in the slide rail 17. Block 18, the bottom of the electric slider 18 is connected with an electric push rod 19, and the bottom of the electric push rod 19 is connected through a connecting plate 21, and a grinding assembly is provided on the connecting plate 21, and the inner bottom of the grinding box 6 is provided with Placing plate 24, is provided with parts fixing assembly in described placing plate ...

Embodiment 2

[0034] see Figure 1~4 , as a kind of surface grinding device for mechanical processing in embodiment 1, comprising a grinding box 6, the left side of the grinding box 6 is provided with a material inlet 7, and the right side of the grinding box 6 is provided with a discharge port 8, so The bottom of the polishing box 6 is connected to the shock absorbing box 3 through several support plates 5, the inside of the shock absorbing box 3 is provided with a shock absorbing assembly, the top of the polishing box 6 is equipped with a slide rail 17, and the slide rail 17 slides Two electric sliders 18 are connected, and the bottom of the electric slider 18 is connected with an electric push rod 19, and the bottom of the electric push rod 19 is connected by a connecting plate 21, and the connecting plate 21 is provided with a grinding assembly, and the grinding The inner bottom of the box 6 is provided with a placement plate 24, the placement plate 24 is provided with a part fixing ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com