An anti-floating fire pump station with rainwater collection function

A rainwater collection and functional technology, applied in pumping stations, general water supply conservation, water supply devices, etc., can solve the problems of single water source and rainwater cannot be used, and achieve the effect of simple structure and water resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

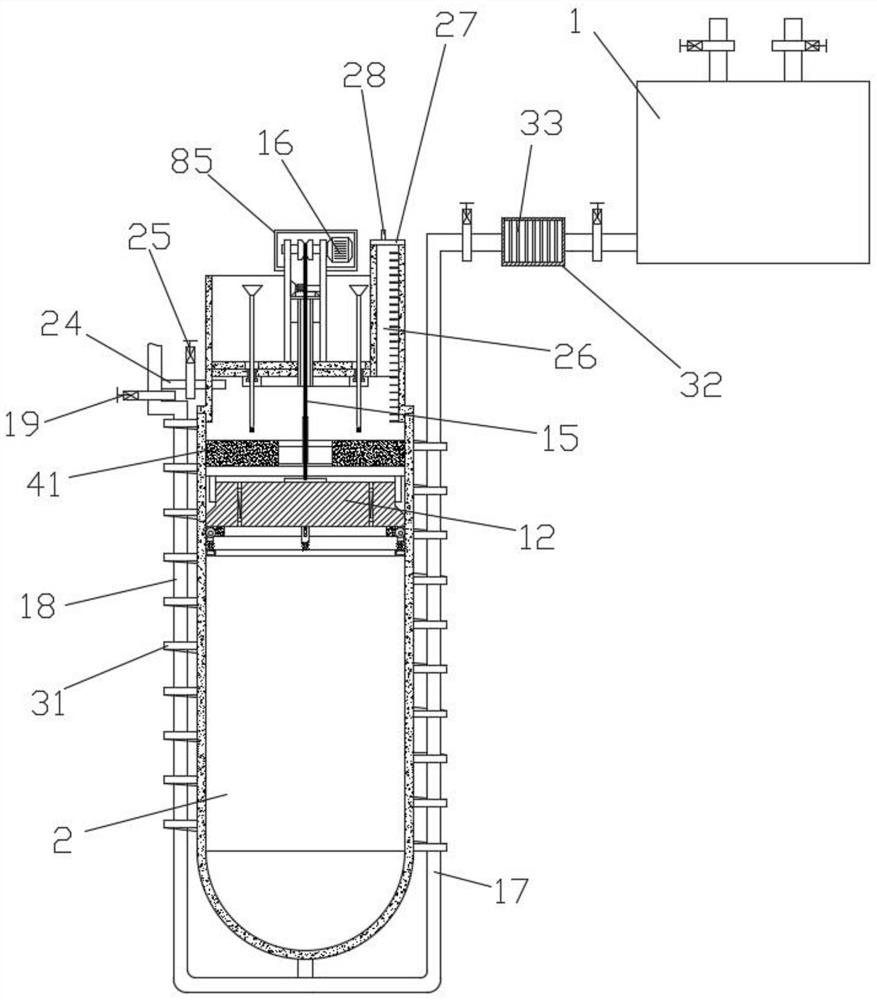

[0028] Such as figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 8 Shown; a kind of anti-floating fire pump station with rainwater collection function, including:

[0029] Pump box 1, water storage tank 2,

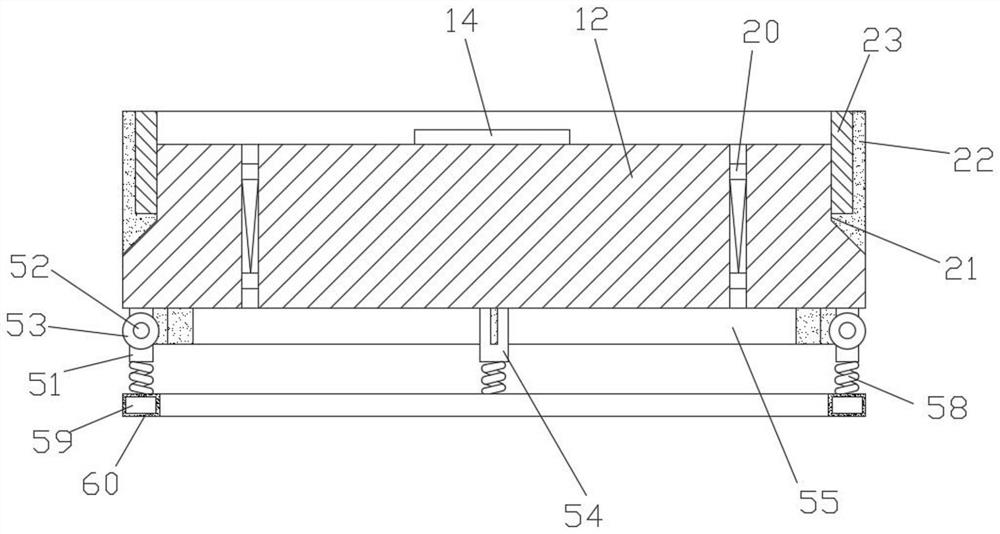

[0030] The water storage tank 2 is provided with a piston plate 12, the top of the piston plate 12 is equipped with a support frame 14, the top of the support frame 14 is connected with a traction cable 15, and the traction cable 15 is wound on the winding motor 16, and the winding motor 16 is fixedly installed On the top of the water storage tank 2, the bottom of the water storage tank 2 is connected with an outlet pipeline 17, and the outlet pipeline 17 is connected with a municipal water supply pipeline 18; Connect pump box 1;

[0031] A one-way valve 20 is installed on the piston plate 12, a water storage tank 71 is provided on the top of the water storage tank 2, and a support tube 72 is provided in the middle of the water storage tank 71. The...

Embodiment 2

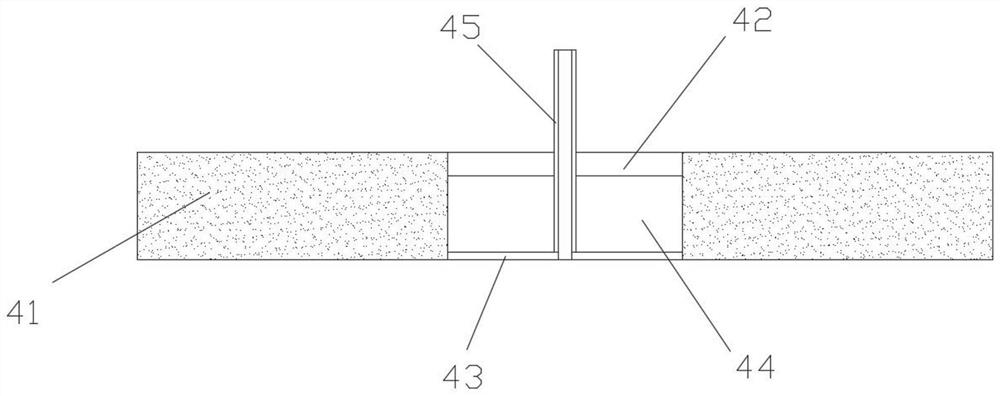

[0035] On the basis of Example 1, such as figure 1 , image 3 As shown; the water storage tank 2 is provided with a floating plate 41, the middle part of the floating plate 41 is provided with a permeable perforation 42, and the bottom end of the permeable perforation 42 is fixed with a supporting backing plate 43, and the supporting backing plate 43 has perforations, and the supporting backing plate 43 top A permeable sponge 44 is laid, a sealing spring 91 is fixed at the lower end of the diversion tube 82, and a sealing plug 92 is fixed at the lower end of the sealing spring 91. The sealing plug 92 can be inserted into the inside of the draft tube 82 by moving upwards. The sealing plug 92 is located on the upper part of the floating plate 41.

[0036]When the amount of water stored in the reservoir 71 is too much, when it overflows the filter funnel 86, the water flow enters the water storage tank 2 through the guide tube 82, and fills the water storage tank 2, so as to faci...

Embodiment 3

[0038] On the basis of Example 1, such as figure 1 , figure 2 As shown; a check valve 20 is installed on the piston plate 12, and both sides of the upper part of the piston plate 12 are provided with an installation ring groove 21, and a sealing rubber ring 22 and a limit screw sleeve 23 are installed in the installation ring groove 21, and the limit screw sleeve 23 Installed in the installation ring groove 21 through threaded connection, the outer surface of the sealing rubber ring 22 is set close to the inner wall of the water storage tank 2, the upper part of the water storage tank 2 is connected with a water injection pipe 24, and the water injection pipe 24 is connected to the municipal water supply pipeline 18. A shut-off valve 25 is installed on the water pipe 24, the connection between the water storage tank 2 and the water injection pipe 24 is located on the upper part of the piston plate 12, the upper part of the water storage tank 2 is provided with an inspection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com