Quick-frozen poached egg and production method thereof

A production method and technology for poached eggs, which are applied to the preservation of eggs by freezing/cooling, egg preservation, food freezing, etc., can solve the problems of stabbed cells and tissues, high protein moisture content, loss of elasticity of poached eggs, etc. Moisture content, the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A production method for quick-frozen poached eggs, comprising the following steps:

[0029] Step 1. Preheating: Set the surface fire of the oven to 145°C, the bottom fire to 105°C, and preheat for 30 minutes. At this time, the temperature in the oven is 158°C; put the mold in the oven to preheat to its temperature of 72°C;

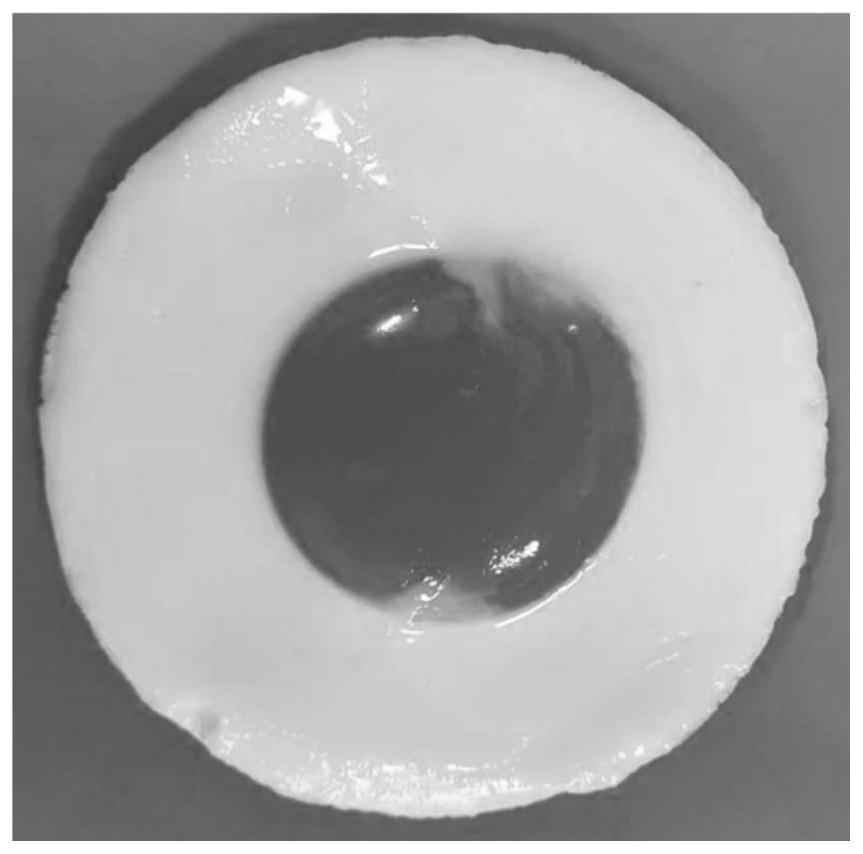

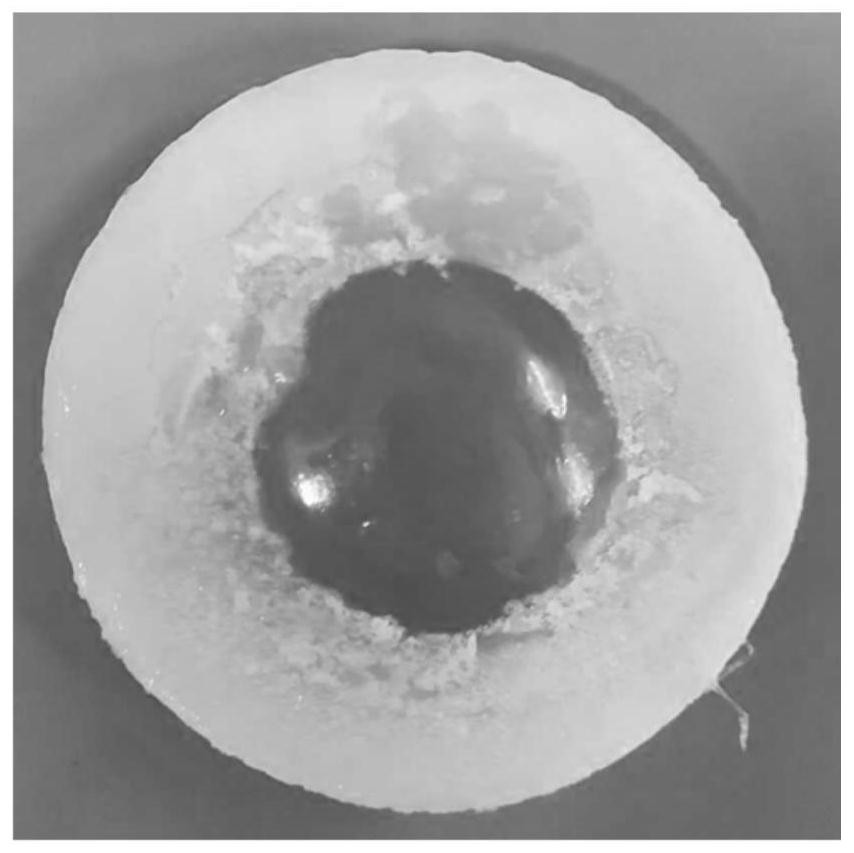

[0030] Step 2. Beat eggs: apply 0.3g of corn oil to the mold, beat the egg into the center of the mold, the egg white will solidify in about 5 seconds, and the egg yolk will be in the middle;

[0031] Step 3. Baking: Put the mold in step 2 together with the eggs in the oven for baking. At this time, the temperature of the oven is still at 158°C, the baking time is 5 minutes, and the demoulding is completed within 2 minutes;

[0032] Step 4. Cooling: Send the poached eggs baked in step 3 into a cooling room for cooling. The temperature is 20°C and the humidity is 40%. Cool until the center temperature of the poached eggs is 30°C. At this time, the eg...

Embodiment 2

[0037] A production method for quick-frozen poached eggs, comprising the following steps:

[0038] Step 1. Preheating: set the surface fire of the oven to 148°C, the bottom fire to 107°C, and preheat for 30 minutes. At this time, the temperature in the oven is 164°C; put the mold in the oven to preheat to its temperature of 75°C;

[0039] Step 2. Beat eggs: apply 0.2g of corn oil to the mold, beat the egg into the center of the mold, the egg white will solidify in about 4 seconds, and the egg yolk will be in the middle;

[0040] Step 3. Baking: Put the mold in step 2 together with the eggs in the oven for baking. At this time, the temperature of the oven is still at 164°C, the baking time is 4min45s, and the demoulding is completed within 1min30s;

[0041] Step 4. Cooling: Send the poached egg baked in step 3 into a cooling room for cooling, the temperature is 22°C, humidity 45%, and the temperature of the center of the poached egg is 32°C, at this time, the egg white moisture...

Embodiment 3

[0046] A production method for quick-frozen poached eggs, comprising the following steps:

[0047] Step 1. Preheating: Set the surface fire of the oven to 150°C, the bottom fire to 110°C, and preheat for 25 minutes. At this time, the temperature in the oven is 167°C; put the mold in the oven to preheat to its temperature of 78°C;

[0048] Step 2. Beat eggs: apply 0.2g of corn oil to the mold, beat the egg into the center of the mold, the egg white will solidify in about 3 seconds, and the egg yolk will be in the middle;

[0049] Step 3. Baking: Put the mold in step 2 together with the eggs in the oven for baking. At this time, the temperature of the oven is still at 167°C, the baking time is 4min40s, and the demoulding is completed in 1min40s;

[0050] Step 4. Cooling: Send the poached eggs baked in step 3 into a cooling room for cooling. The temperature is 18°C and the humidity is 39%. Cool until the center temperature of the poached eggs is 28°C. At this time, the egg whit...

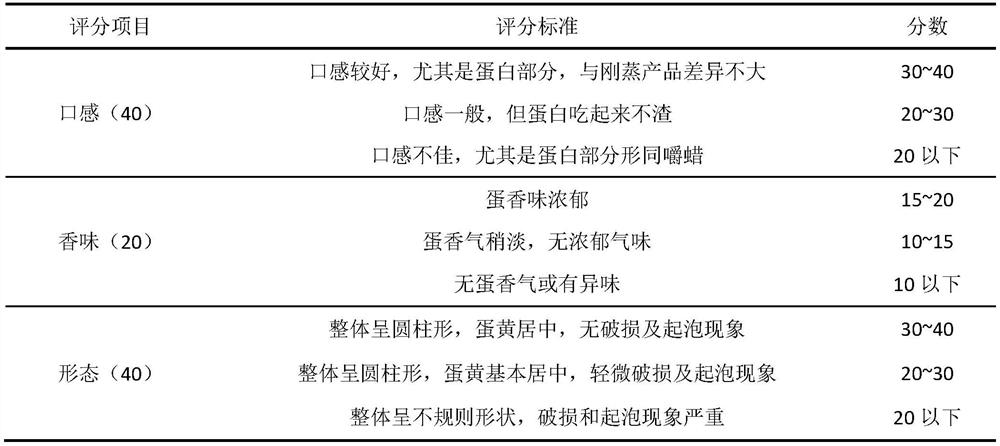

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com