Method for preparing aluminum sulfate solid by using byproduct aluminum mud

A technology of solid sulfuric acid and aluminum mud, applied in aluminum sulfate, aluminum sulfur compounds, etc., can solve problems such as environmental pollution, and achieve the effects of reducing waste pollution, stable product quality, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

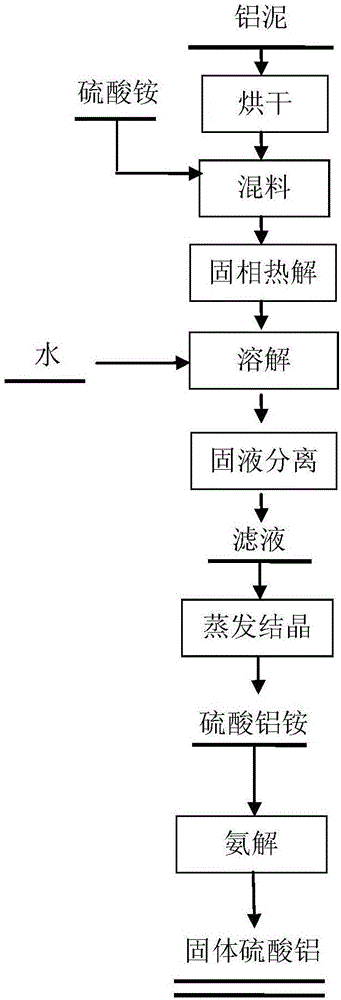

Image

Examples

Embodiment 1

[0024] 1) dry milling

[0025] Take 1 ton of dried aluminum slime, whose Al2O3 content is 60%, add 2.37 tons of ammonium sulfate, put it into a ball mill tank and fully mix and grind for 1 hour to obtain a mixed powder of 40-60 mesh aluminum slime and ammonium sulfate;

[0026] 2) High temperature pyrolysis

[0027] Pyrolyze the mixed powder of aluminum slime and ammonium sulfate obtained in step 1) at 300°C for 1 hour. During the pyrolysis process, mix the aluminum slime and ammonium sulfate to make it fully pyrolyzed, and mix the pyrolyzed The powder is added into the water according to the mass ratio of the mixed powder and water as 1:8, fully dissolved at 70°C for 1 hour with heat preservation and stirring, filtered, and the filtrate is evaporated and crystallized to obtain aluminum ammonium sulfate crystals;

[0028] 3) High temperature ammonia solution

[0029] Ammonium aluminum sulfate crystals were subjected to high-temperature ammonium hydrolysis at 400°C for 2 hour...

Embodiment 2

[0032] 1) dry milling

[0033] Take 1 ton of dried aluminum slime, whose Al2O3 content is 80%, add 5.17 tons of ammonium sulfate, and put it into a ball mill tank to fully mix and grind for 3 hours to obtain a mixed powder of 40-60 mesh aluminum slime and ammonium sulfate;

[0034] 2) High temperature pyrolysis

[0035] Pyrolyze the aluminum slime and ammonium sulfate mixed powder obtained in step 1) at 500°C for 3 hours. During the pyrolysis process, mix the aluminum slime and ammonium sulfate to make it fully pyrolyzed, and mix the pyrolyzed The powder is added into water according to the mass ratio of mixed powder and water as 1:10, fully dissolved at 100°C for 3 hours with heat preservation and stirring, filtered, and the filtrate is evaporated and crystallized to obtain aluminum ammonium sulfate crystals;

[0036] 3) High temperature ammonia solution

[0037] Ammonium aluminum sulfate crystals were subjected to high-temperature ammonium hydrolysis at 600°C for 4 hours t...

Embodiment 3

[0040] 1) dry milling

[0041] Take 1 ton of dried aluminum slime, whose Al2O3 content is 70%, add 3.68 tons of ammonium sulfate, put it in a ball mill tank and fully mix and grind for 2 hours to obtain -60 mesh aluminum slime and ammonium sulfate mixed powder;

[0042] 2) High temperature pyrolysis

[0043] Pyrolyze the aluminum slime and ammonium sulfate mixed powder obtained in step 1) at 400°C for 2 hours. During the pyrolysis process, mix the aluminum slime and ammonium sulfate to make it fully pyrolyzed, and mix the pyrolyzed The powder is added into water according to the mass ratio of mixed powder and water as 1:9, fully dissolved at 80°C for 2 hours with heat preservation and stirring, filtered, and the filtrate is evaporated and crystallized to obtain aluminum ammonium sulfate crystals;

[0044] 3) High temperature ammonia solution

[0045] Ammonium aluminum sulfate crystals were subjected to high-temperature ammonium hydrolysis at 500°C for 3 hours to obtain 2.24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com