Cigarette cooling section, preparation method thereof, cooling filter tip comprising cigarette cooling section and low-temperature cigarette

A technology of low-temperature cigarettes and cooling section, which is applied in the fields of tobacco, cigar manufacturing, application, etc. It can solve the problems of limited length and diameter of the mouth rod, blockage of smoke channels, and decrease of smoke volume, so as to ensure stability and controllability Sexuality, reducing smoke being blocked, increasing the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

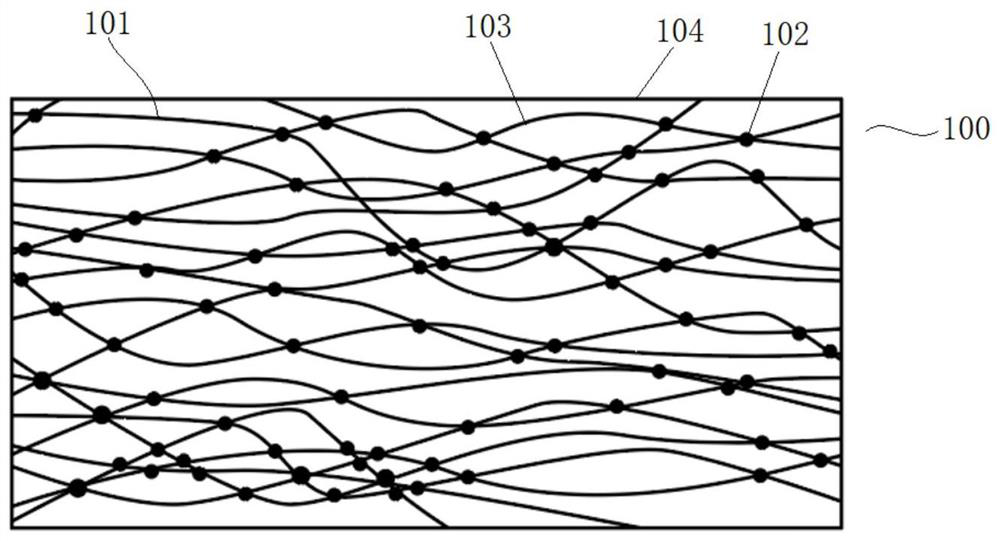

[0050] Such as figure 1 As shown, the cigarette cooling section 100 proposed in the first embodiment includes: a tow 101 and a tow section 102 for lowering the temperature of the smoke, the tow section 102 is fixedly connected to a plurality of monofilaments 103 in the tow 101, Furthermore, cross-linking points are formed among the plurality of monofilaments 103 , so that the linear filament bundle 101 produces a network structure. In this way, the airflow passages in the tow 101 are not only numerous but also smooth, which can reduce the phenomenon of smoke being blocked, and at the same time, the contact area between the smoke and the tow section 102 is increased, so that the cooling efficiency of the smoke can be improved, and the cooling effect is good. The cigarette cooling section 100 also includes a first molding paper 104 covering the tow 101 and the tow section 102 .

[0051] Further, the tow section 102 is used to increase the hardness of the cigarette cooling secti...

Embodiment 2

[0083] Such as figure 1 As shown, the cigarette cooling section 100 proposed in the second embodiment includes: a tow 101 and a tow section 102 for reducing the temperature of the smoke, the tow section 102 is fixedly connected to a plurality of monofilaments 103 in the tow 101, Furthermore, cross-linking points are formed among the plurality of monofilaments 103 , so that the linear filament bundle 101 produces a network structure. In this way, the airflow passages in the tow 101 are not only numerous but also smooth, which can reduce the phenomenon of smoke being blocked, and at the same time, the contact area between the smoke and the tow section 102 is increased, so that the cooling efficiency of the smoke can be improved, and the cooling effect is good. The cigarette cooling section 100 also includes a first molding paper 104 covering the tow 101 and the tow section 102 .

[0084] Further, the tow section 102 is used to increase the hardness of the cigarette cooling sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas permeability | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com