Flotation separation device for preparing boric acid from boron ore

A separation device and flotation technology, applied in flotation, solid separation, etc., can solve the problems of single function, low work efficiency, inconvenient popularization and use, etc., and achieve the effect of convenient operation, improved work efficiency and diversified functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

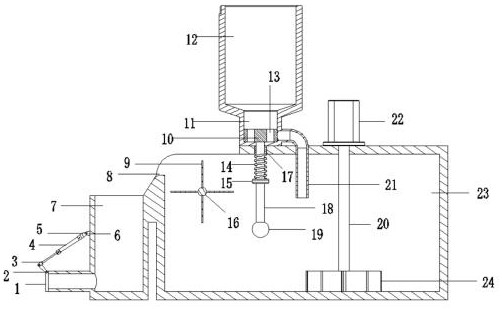

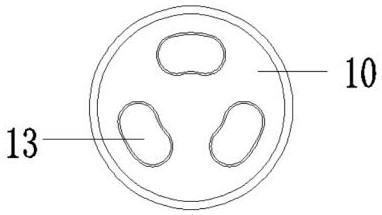

[0027] Such as Figure 1-2 Shown, a kind of flotation separation device for producing boric acid from boron ore comprises:

[0028] A flotation chamber 23, the top of the flotation chamber 23 is provided with a cover plate, one end of the top is open, and an overflow port 8 is formed between it and its side wall;

[0029] Centrifugal assembly, described centrifugal assembly comprises the rotating shaft 20 that is vertically rotatably connected on the cover plate and the lower end extends into the flotation chamber 23, the end of the rotating shaft 20 extending into the flotation chamber 23 is provided with an impeller 24, the rotating shaft 20 is driven to rotate by the motor 22 installed on the cover plate, the motor 22 rotates and drives the rotating shaft 20 to rotate, and then the impeller 24 is rotated to centrifugally stir the ore pulp stored in the flotation bin 23;

[0030] A collection bin 7, the collection bin 7 is located on the outer wall of the flotation bin 23 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com