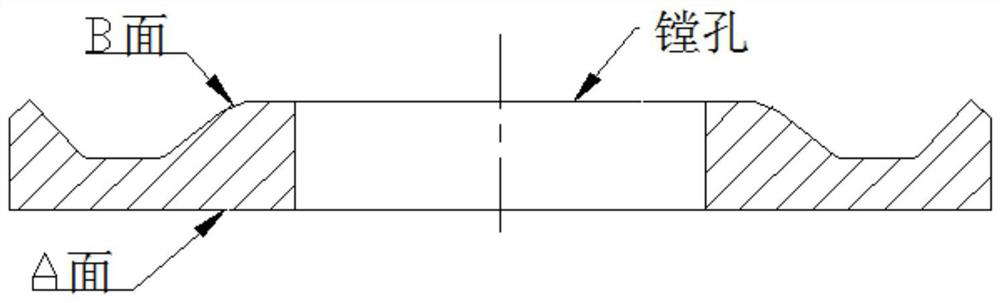

Machining process of damping bowl

A processing technology and damping technology, applied in the field of processing technology of damping bowl, can solve problems such as large error and poor consistency, and achieve the effect of reducing multiple clamping, reducing scrap causes and shortening processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

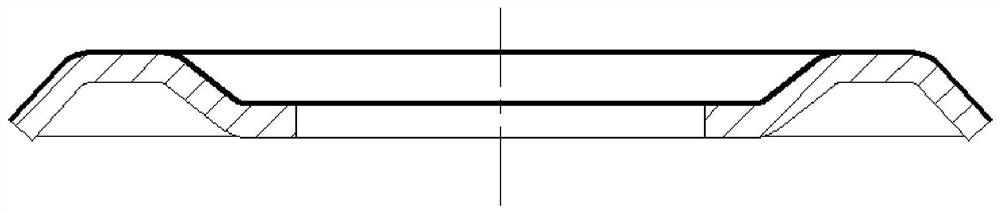

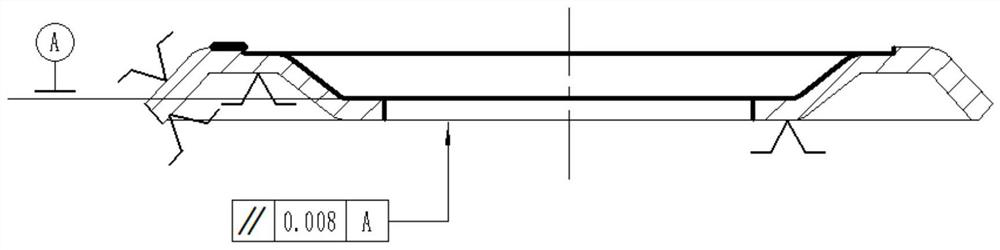

[0029] Embodiment 1: a kind of processing technology of damping bowl, comprises the following steps:

[0030] a) blanking: blanking with a lathe according to the forged length and diameter of the pre-processed damping bowl, to obtain the processed raw blank;

[0031] b) One-time rough turning: the raw material of rough turning shall be processed according to Type II die forgings, and meet the relevant requirements of GJB5040-2001 to obtain forged parts;

[0032] c) Primary heat treatment (stress annealing): place the forged piece in a well-type furnace for annealing for 1 hour, and the annealing temperature is 570°C;

[0033] d) Secondary heat treatment (stress annealing): place the annealed forged piece in an aluminum alloy furnace for annealing for 1 hour at an annealing temperature of 390°C to obtain a secondary annealed forged piece;

[0034] e) Secondary rough turning: Secondary rough turning forging forged parts, to ensure that the runout tolerance of the outer circle r...

Embodiment 2

[0043] Embodiment 2: a kind of processing technology of damping bowl, comprises the following steps:

[0044] a) blanking: blanking with a lathe according to the forged length and diameter of the pre-processed damping bowl, to obtain the processed raw blank;

[0045] b) One-time rough machining (forging): the raw material of the rough car is processed according to the type II die forgings, which meets the relevant requirements of GJB5040-2001, and the forged parts are obtained;

[0046] c) Primary heat treatment (stress annealing): put the forged part in a pit furnace for 1.5 hours, and the annealing temperature is 600 °C;

[0047] d) Secondary heat treatment (stress annealing): put the annealed forged blank into an aluminum alloy furnace for 1.5 hours, and the annealing temperature is 410°C to obtain a secondary annealed forged piece;

[0048] e) Secondary rough turning: the shape of the forged part is roughed again to ensure that the run-out tolerance of the outer circle re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com