A kind of steel slag conditioning agent and using method thereof

A technology for conditioning agent and steel slag, applied in the field of iron and steel smelting, can solve the problems of low activity, poor stability, and reduce the content of calcium oxide and magnesium oxide, and achieve the effects of improving the gelling activity, increasing the strength and shortening the setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

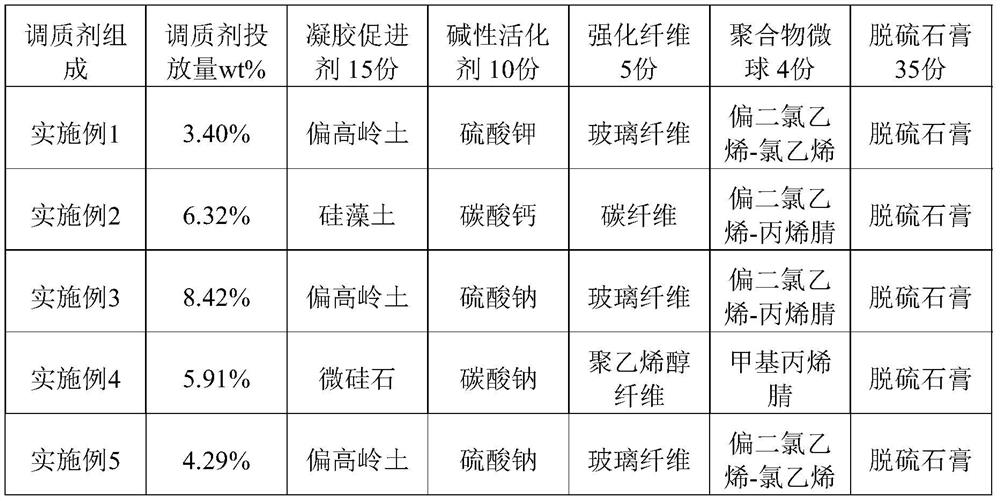

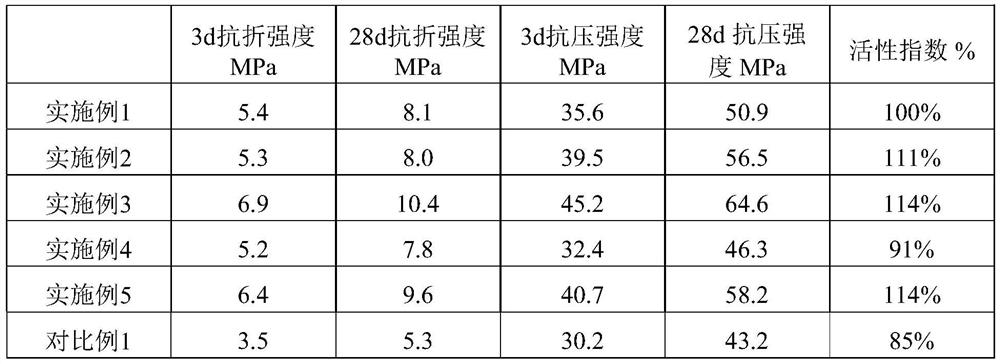

Embodiment 1

[0046] After the molten steel is smelted in the converter, before the steel slag is discharged, the temperature of the steel slag is controlled at 700°C, and argon is blown to the bottom of the steel slag tank to keep the liquid steel slag stirring clockwise smoothly. Quickly add the components of conditioner on the liquid surface, including gel accelerator, alkaline activator, reinforcing fiber, and desulfurized gypsum, stir for 2 minutes, and slowly cool to 450°C, add polymer microspheres, and keep blowing argon for 40 seconds at the same time. Then the steel slag is discharged, cooled to room temperature, crushed and ground to obtain tempered steel slag powder.

Embodiment 2

[0048] After the molten steel is smelted in the converter, before the steel slag is discharged, the temperature of the steel slag is controlled at 780°C, and argon is blown to the bottom of the steel slag tank to keep the liquid steel slag stirring clockwise smoothly. Quickly add the components of conditioner on the liquid surface, including gel accelerator, alkaline activator, reinforcing fiber, and desulfurized gypsum, stir for 5 minutes, and slowly cool to 490°C, add polymer microspheres, and keep blowing argon for 30 seconds at the same time. Then the steel slag is discharged, cooled to room temperature, crushed and ground to obtain tempered steel slag powder.

Embodiment 3

[0050] After the molten steel is smelted in the converter, before the steel slag is discharged, the temperature of the steel slag is controlled at 800°C, and argon is blown to the bottom of the steel slag tank to keep the liquid steel slag stirring clockwise smoothly. Quickly add the components of conditioner on the liquid surface, including gel accelerator, alkaline activator, reinforcing fiber, and desulfurized gypsum, stir for 5 minutes, and slowly cool to 500°C, add polymer microspheres, and keep blowing argon for 30 seconds at the same time. Then the steel slag is discharged, cooled to room temperature, crushed and ground to obtain tempered steel slag powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com