Self-repairing material and preparation method thereof

A technology of self-healing materials and polymers, which is applied in the field of new materials, can solve the problems of expensive replacement costs, etc., and achieve the effects of good solvent performance, good performance, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

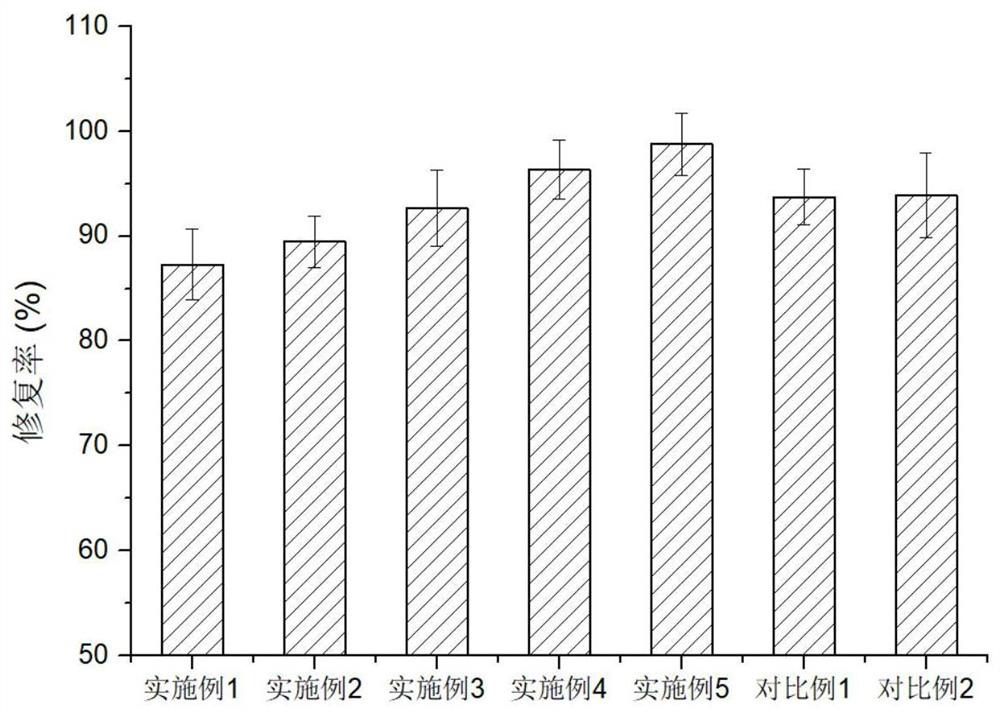

Embodiment 1

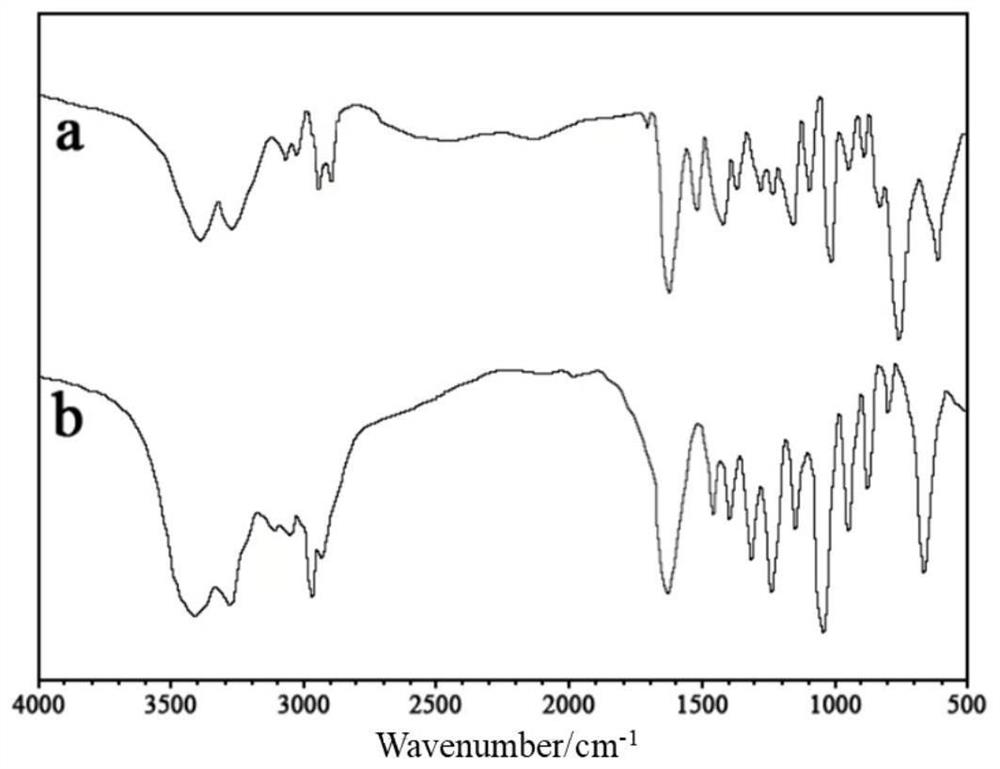

[0032] A method for preparing a self-healing material,

[0033] Preparation of polyamide polymer: add succinamide and furfural to methanol, stir for 1 hour, add THF solution containing 1,4-diisocyanobenzene and 2-hydroxypropionic acid, react at 70°C for 48 hours, reduce pressure The solvent was removed by rotary evaporation to obtain the thick product of polyamide polymer; the thick product was dissolved in dichloromethane, and ether was added to separate out the solid, which was repeated 3 times, and the solvent was evaporated under reduced pressure, and dried to obtain the polyamide polymer (yield 58.37%). The addition amount of succinamide is 20wt% of methanol, the addition amount of furfural is 60wt% of methanol, the addition amount of 1,4-diisocyanobenzene in THF solution is 16wt% of THF, the addition amount of 2-hydroxypropionic acid in THF solution The addition amount is 40wt% of THF, the addition amount of THF solution is 200wt% of methanol solution, the addition amou...

Embodiment 2

[0039] A method for preparing a self-healing material,

[0040]Preparation of polyamide polymer: Add succinamide and furfural to methanol, stir for 1 hour, add THF solution containing 1,4-diisocyanobenzene and 2,2-dimethylolpropionic acid, and add succinamide and furfural at a temperature of 70°C React for 48 hours, remove the solvent by rotary evaporation under reduced pressure, and obtain the crude product of polyamide polymer; dissolve the crude product in dichloromethane, add ether to precipitate the solid, repeat 3 times, evaporate the solvent under reduced pressure, and dry to obtain polyamide Polymer (59.41% yield). The addition amount of succinamide is 20wt% of methanol, the addition amount of furfural is 60wt% of methanol, the addition amount of 1,4-diisocyanobenzene in THF solution is 16wt% of THF, and the addition amount of 2,2-dihydroxy The addition of methacrylic acid is 40wt% of THF, the addition of THF solution is 200wt% of methanol solution, the addition of cr...

Embodiment 3

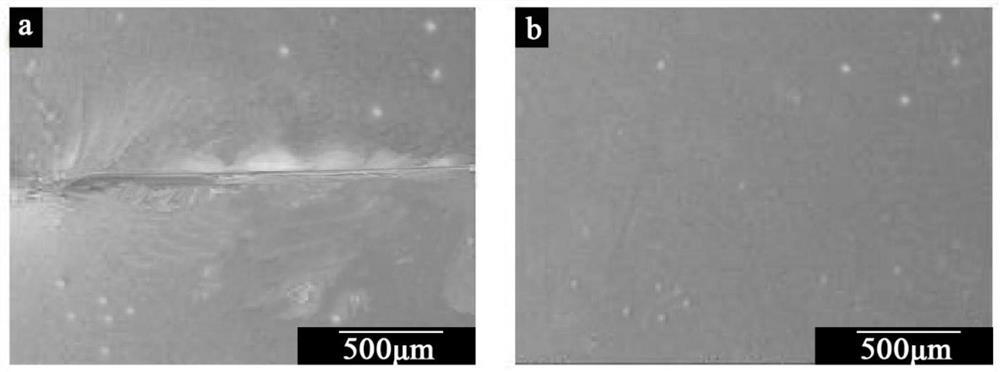

[0046] A method for preparing a self-healing material,

[0047] Preparation of self-healing material: the mixture of the polyamide polymer shown in formula (1) and the polyamide polymer shown in formula (2) and diphenylmethyl bismaleimide are added to dioxygen In the six rings, under the protection of nitrogen, stir at a temperature of 90°C for 20h, take it out and pour it into a mold, and continue to react at a temperature of 60°C for 48h to obtain a self-healing material. The addition amount of the polyamide polymer mixture is 15wt% of dioxane, and the polyamide polymer represented by formula (1) is mixed with the polyamide polymer represented by formula (2) in a mass ratio of 1:4 , the addition of benzhydryl bismaleimide is 9wt% of dioxane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com