Polyperfluoroethylene propylene resin mixture for high-speed extrusion of thin-walled cables and preparation method thereof

A technology of polyperfluoroethylene propylene and resin mixture, which is applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., and can solve problems such as excessive breakdown, viscose, and unevenness, so as to slow down melt fracture and solve Adhesive, excellent lubricity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

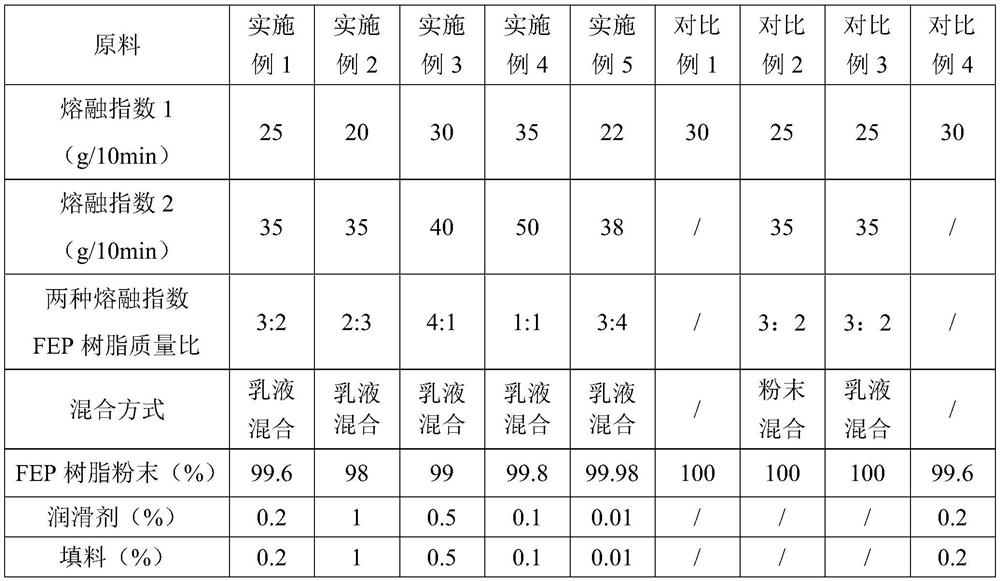

Embodiment 1

[0033] (1) Mix the FEP resin emulsion with powder melt index of 25g / 10min and 35g / 10min according to the mass ratio of 3:2, condense and dry to obtain FEP resin powder, and its melt flow rate under the condition of 372°C and 5kg is 30g / 10min;

[0034] (2) Spray 0.2% lubricant silicone powder and 0.2% filler kaolin onto 99.6% FEP resin powder, and stir evenly to obtain a mixture;

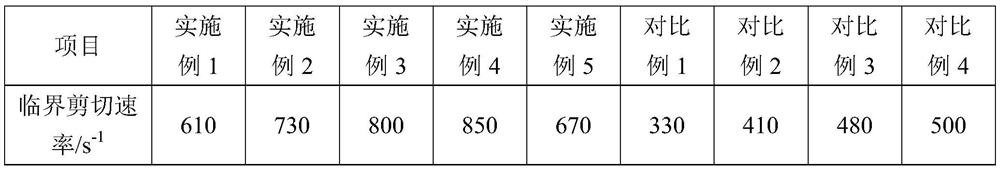

[0035] (3) Melt, process and granulate the mixture on a devolatilization granulator. The temperatures in the feeding section, melting section, mixing section, devolatilization section, and metering section are respectively: 320°C, 370°C, 380°C, 380°C, At 385°C, a polyperfluoroethylene propylene resin mixture for high-speed extrusion of thin-walled cables was obtained, and its critical shear rate was tested at a temperature of 372°C;

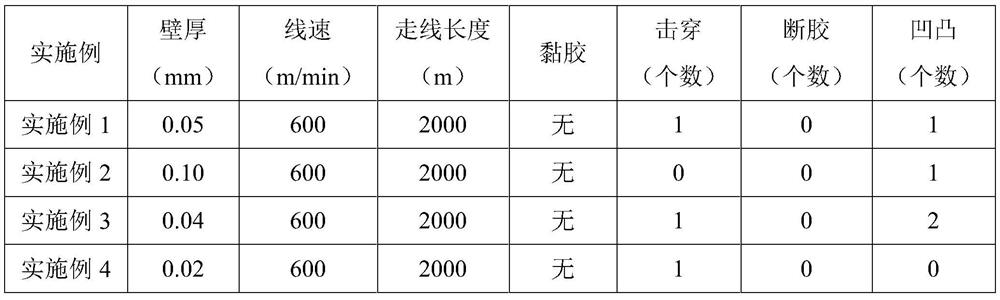

[0036] (4) Add 3% of the total mass of white masterbatch to the prepared polyperfluoroethylene propylene resin mixture for high-speed extrusion of thin-walled cables f...

Embodiment 2

[0038] (1) Mix the FEP resin emulsion with powder melt index of 20g / 10min and 35g / 10min according to the mass ratio of 2:3, condense and dry to obtain FEP resin powder, and its melt flow rate under the condition of 372°C and 5kg is 25g / 10min;

[0039] (2) Spray 1% lubricant silicone powder and 1% filler kaolin onto 98% FEP resin powder, and stir evenly to obtain a mixture;

[0040] (3) The mixture is melt-processed and granulated on a devolatilization granulator. The temperatures of the feeding section, melting section, mixing section, devolatilization section, and metering section are respectively: 320°C, 380°C, 390°C, 390°C, At 395°C, a polyperfluoroethylene propylene resin mixture for high-speed extrusion of thin-walled cables was obtained, and its critical shear rate was tested at a temperature of 372°C;

[0041] (4) Add 3% of the total mass of white masterbatch to the prepared polyperfluoroethylene propylene resin mixture for high-speed extrusion of thin-walled cables fo...

Embodiment 3

[0043] (1) Mix the FEP resin emulsion with powder melt index of 30g / 10min and 40g / 10min according to the mass ratio of 4:1, condense and dry to obtain FEP resin powder, and its melt flow rate under the condition of 372°C and 5kg is 33g / 10min;

[0044](2) Spray 0.5% lubricant silicone powder and 0.5% filler kaolin onto 99% FEP resin powder, and stir evenly to obtain a mixture;

[0045] (3) The mixture is melt-processed and granulated on a devolatilization granulator. The temperatures of the feeding section, melting section, mixing section, devolatilization section, and metering section are respectively: 310°C, 365°C, 375°C, 375°C, At 380°C, a polyperfluoroethylene propylene resin mixture for high-speed extrusion of thin-walled cables was obtained, and its critical shear rate was tested at a temperature of 372°C;

[0046] (4) Add 3% of the total mass of white masterbatch to the prepared polyperfluoroethylene propylene resin mixture for high-speed extrusion of thin-walled cables...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com