A kind of manufacturing method of x70m pipeline steel plate used under low-cost and ultra-low temperature conditions

A manufacturing method and ultra-low temperature technology, applied in the field of X70M pipeline steel plate manufacturing, can solve the problems of high requirements for pipeline steel, limited plant design, and less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

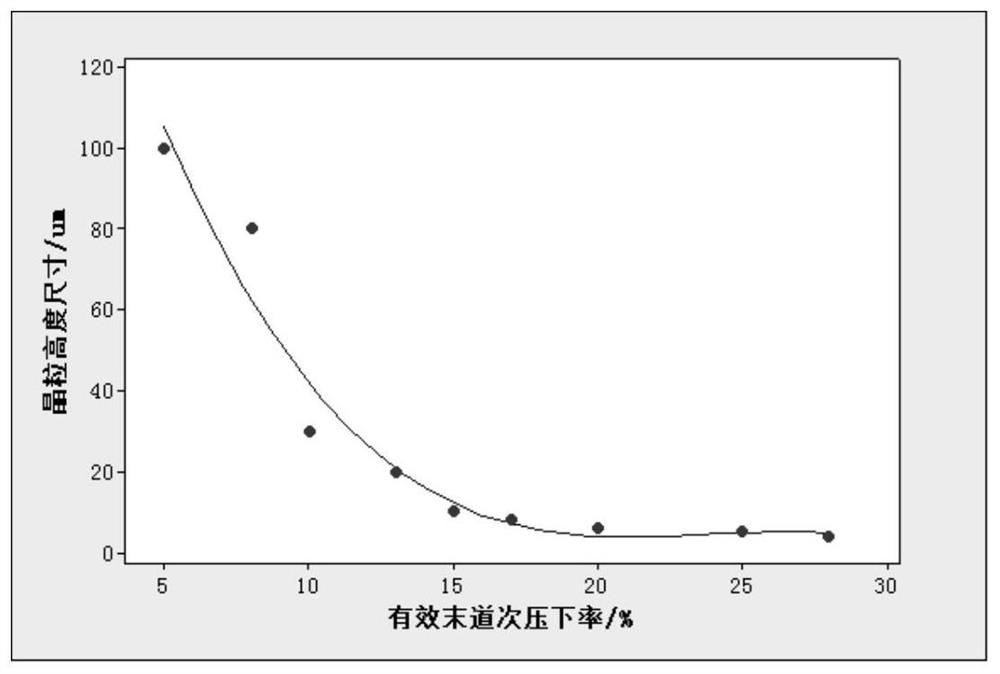

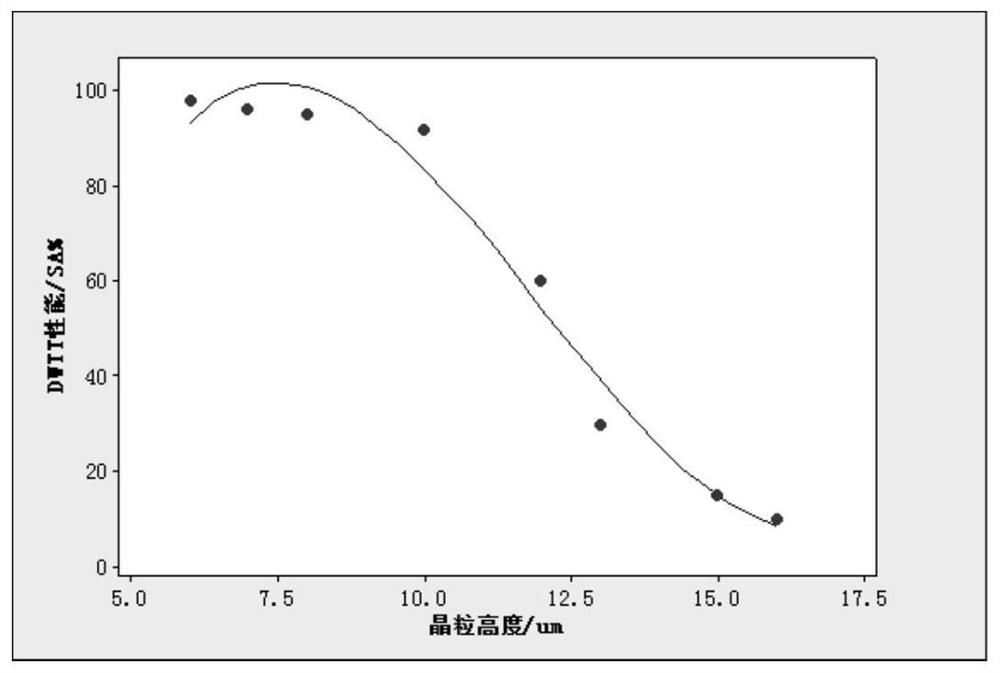

Image

Examples

Embodiment 1-2

[0041] According to the chemical composition range and manufacturing method of the present invention, KR molten iron pretreatment - BOF smelting - RH vacuum degassing - LF refining - RH vacuum degassing - 150mm thickness continuous casting billet continuous casting - continuous casting billet inspection and cleaning - hot charging Sending - billet heating - high-pressure water descaling - rolling - ACC cooling - straightening - steel plate shearing - inspection and storage process steps to manufacture X70M pipeline steel plates used under low-cost and ultra-low temperature conditions.

[0042] The specific process of the above heating, rolling and cooling is as follows: heating the 150mm thick continuous casting slab from 670°C to 1120°C, keeping the soaking section for 40 minutes (Example 1) or heating the 150mm thick continuous casting slab from 660°C to 1100°C, The soaking section was kept for 30 minutes (Example 2), and the continuous casting billet was removed from the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com