Crankshaft blank, crankshaft blank assembling method and crankshaft blank batch manufacturing method

An assembly method and a technology of blanks, which are applied to crankshafts, pump elements, and parts of pumping devices for elastic fluids, etc., can solve the problems of large production area, high input cost, and poor balance of equipment utilization, and reduce the The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

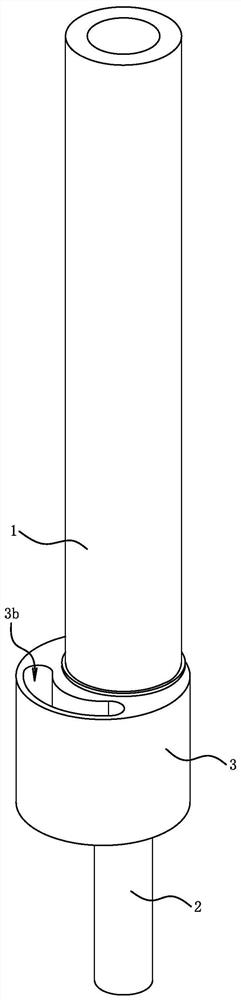

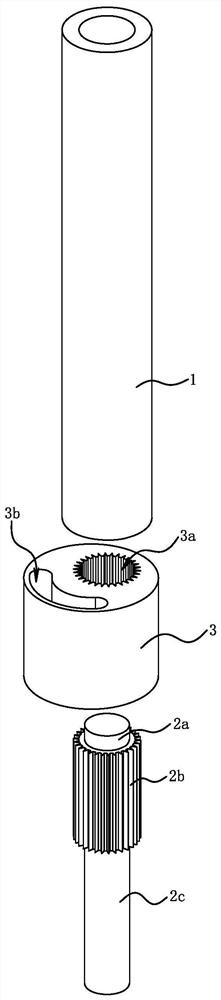

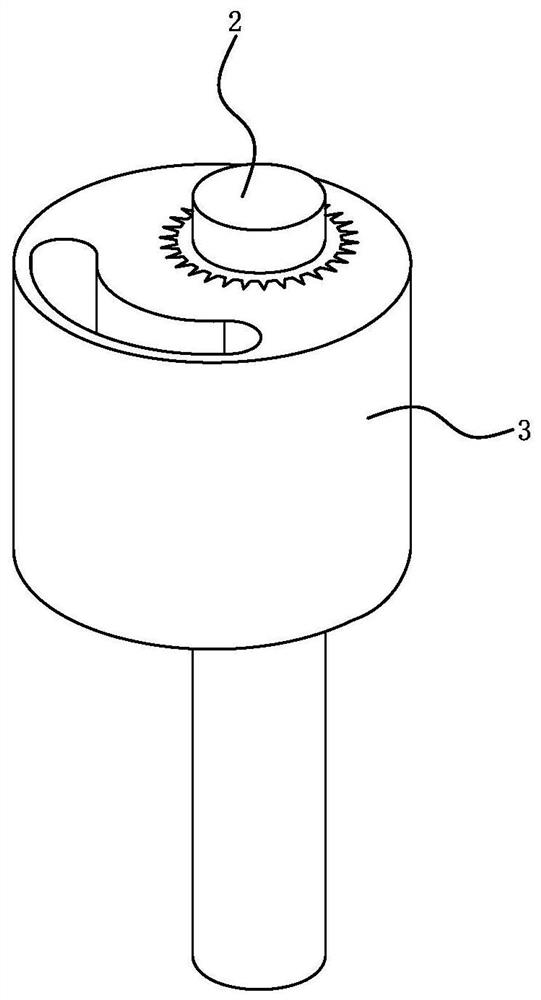

[0034] Such as Figure 1 to Figure 4 As shown, a compressor crankshaft blank is composed of a hollow major shaft 1 , a solid minor shaft 2 and an eccentric sleeve 3 .

[0035] From one end to the other, the short shaft 2 consists of a welding connection section 2a, a spline section 2b and a main shaft section 2c, and the spline section 2b has spline teeth. The eccentric sleeve 3 has a shaft hole 3a inside, the shaft hole 3a deviates from the axis of the eccentric sleeve 3, and the side of the shaft hole 3a has a spline groove. One end of the short shaft 2 is passed through the shaft hole 3a of the eccentric sleeve 3; specifically, the spline section 2b of the short shaft 2 is located in the shaft hole 3a, and the spline t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com