Energy-saving dehydration device for granular biological pesticide

A technology for biological pesticides and dehydration devices, which is applied in the directions of drying solid materials, drying gas layout, lighting and heating equipment, etc., can solve the problems of pesticide properties, low use value of pesticide dehydration devices, and large energy consumption, and improve dehydration efficiency. and dehydration effect, the effect of improving the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

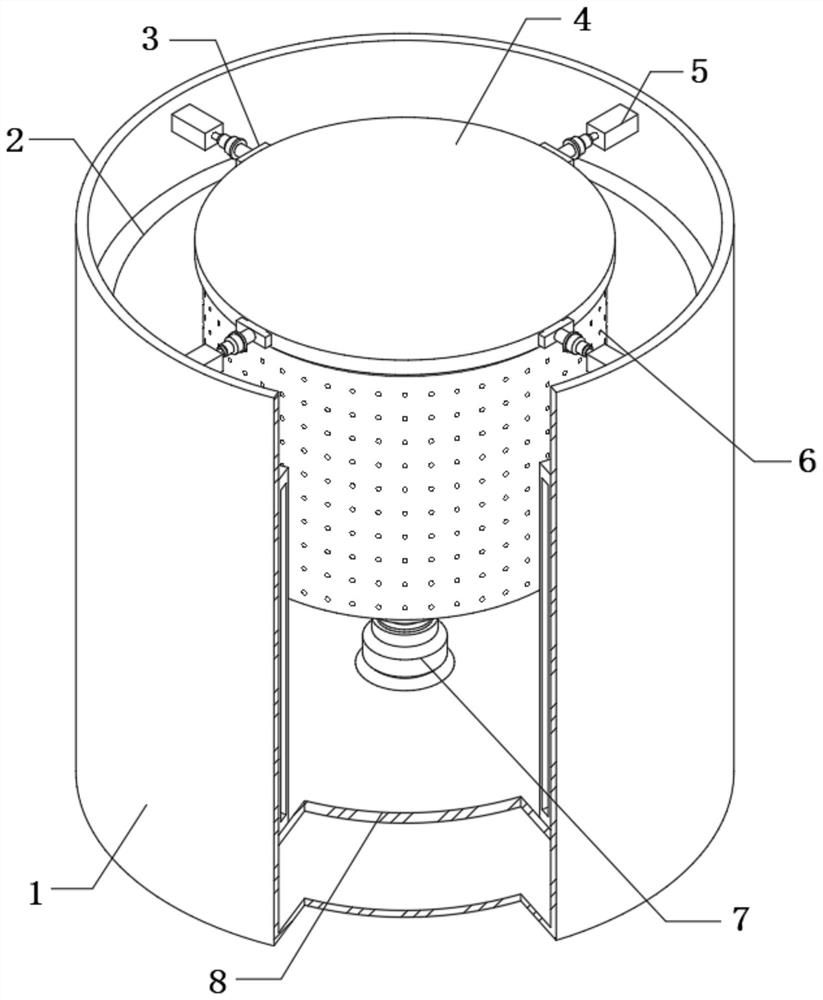

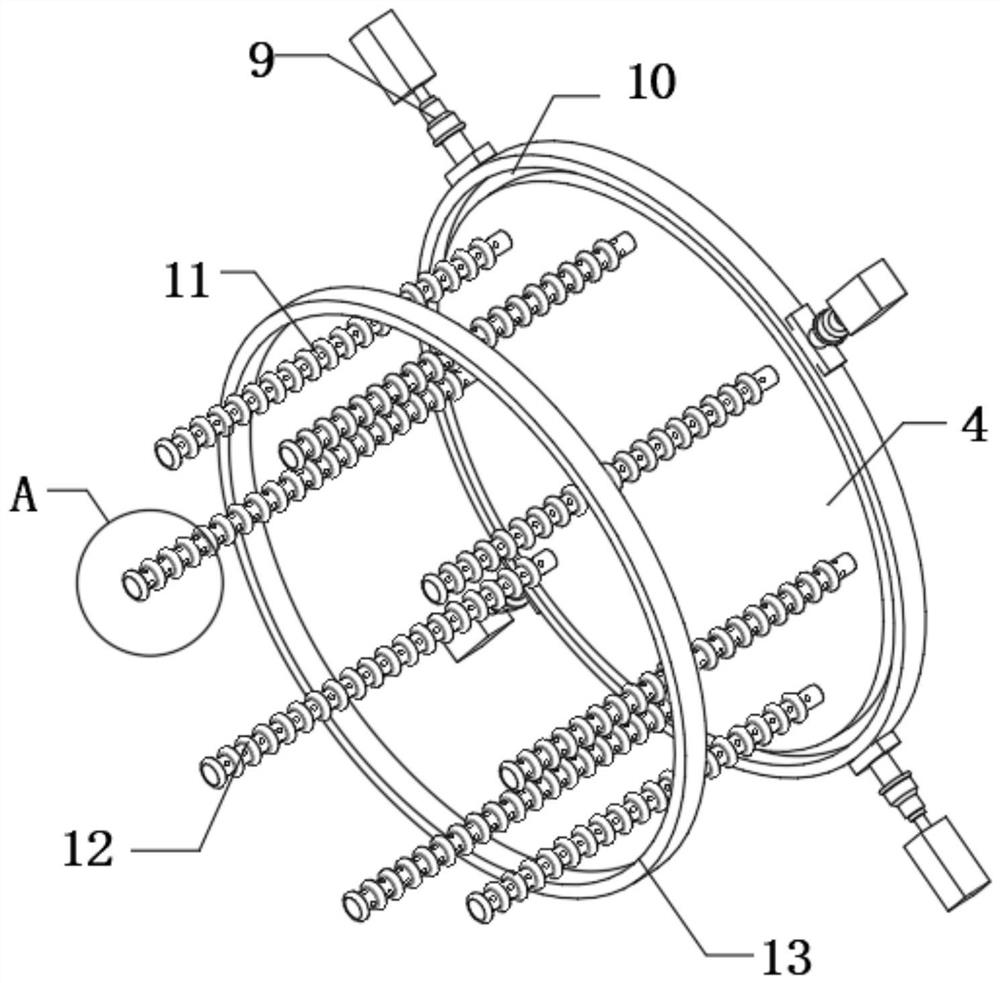

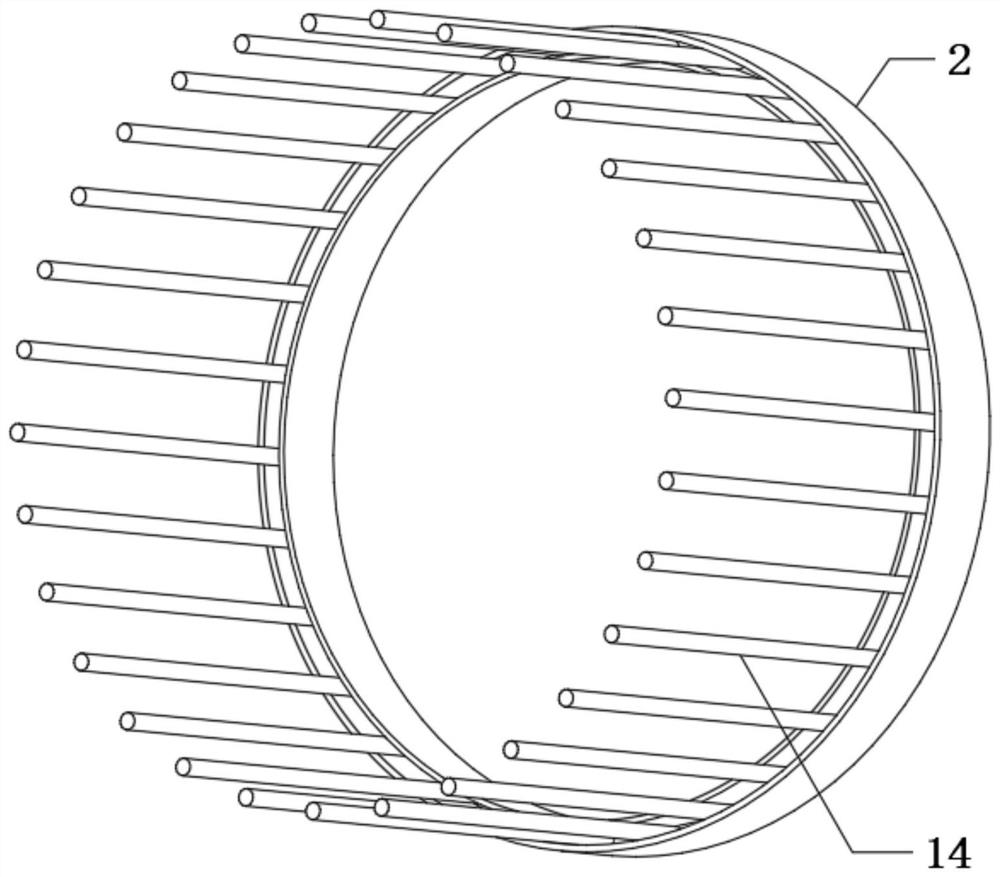

[0026] refer to Figure 1-4 , a granular biopesticide energy-saving dehydration device, comprising a drying box 1, a fixed plate 4 and a dehydration cylinder 6, the top outer wall of the dehydration cylinder 6 is fixedly connected with a rotating ring 13, and the bottom outer wall of the fixed plate 4 is provided with a sliding groove 10, The rotating ring 13 is slidably connected to the inner wall of the sliding groove 10, the outer wall of the bottom of the fixed plate 4 is fixedly connected with the extruding rod 11 equidistantly, and the outer wall of the extruding rod 11 is equidistantly connected with the impact ring 12, and the corners of the impact ring 12 are Arc-shaped structure, the extruding rod 11 is located at the outer wall between every two impact rings 12 and has through holes 15 at equal distances, the outer wall of the dehydration cylinder 6 has water filter holes at equal distances, and the bottom outer wall of the dehydration cylinder 6 is fixedly connected...

Embodiment 2

[0033] refer to Figure 1-5, a granular biopesticide energy-saving dehydration device, comprising a drying box 1, a fixed plate 4 and a dehydration cylinder 6, the top outer wall of the dehydration cylinder 6 is fixedly connected with a rotating ring 13, and the bottom outer wall of the fixed plate 4 is provided with a sliding groove 10, The rotating ring 13 is slidably connected to the inner wall of the sliding groove 10, the outer wall of the bottom of the fixed plate 4 is fixedly connected with the extruding rod 11 equidistantly, and the outer wall of the extruding rod 11 is equidistantly connected with the impact ring 12, and the corners of the impact ring 12 are Arc-shaped structure, the extruding rod 11 is located at the outer wall between every two impact rings 12 and has through holes 15 at equal distances, the outer wall of the dehydration cylinder 6 has water filter holes at equal distances, and the bottom outer wall of the dehydration cylinder 6 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com