Tempered glass flatness online detection system and detection method thereof

A technology of tempered glass and detection system, applied in measuring devices, instruments, and optical devices, etc., can solve problems such as inability to achieve consistent quality control, extremely high requirements for installation and debugging accuracy, and difficult to control measurement accuracy and errors. The effect of low cost, convenient debugging and simple parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

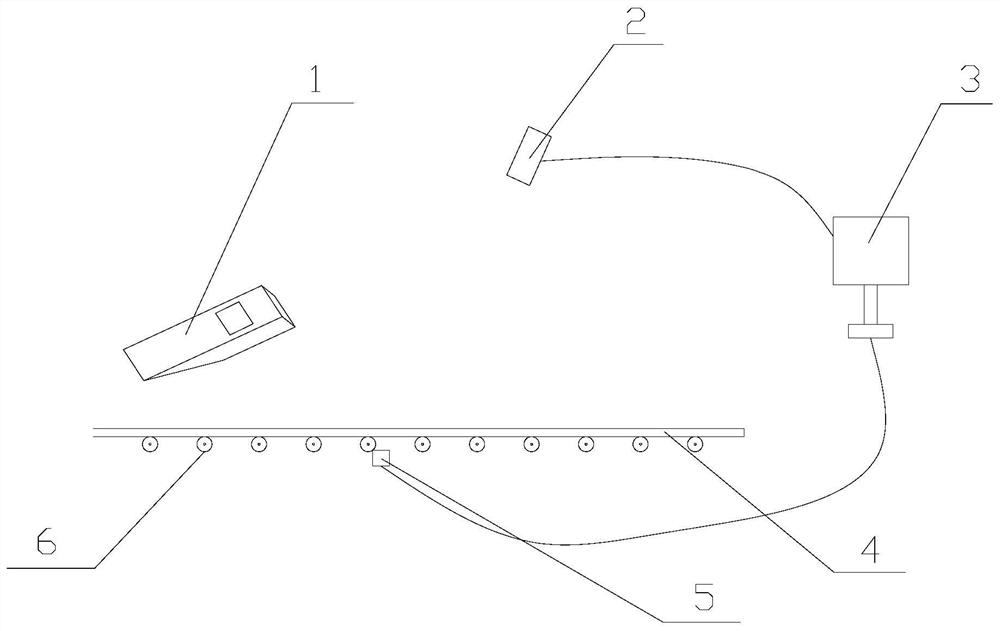

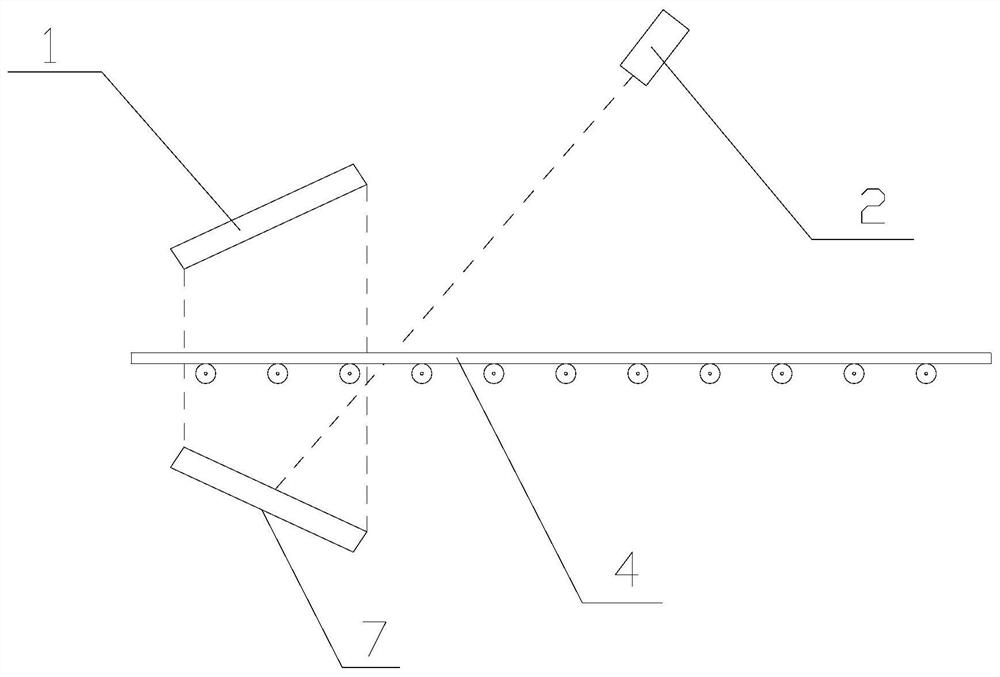

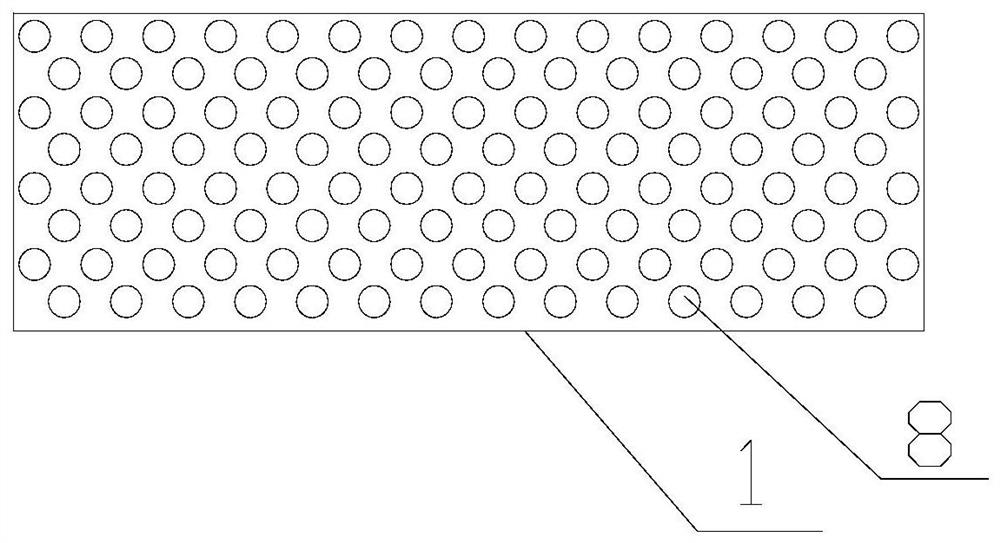

[0026] Such as Figure 1-3 , tempered glass flatness on-line detection system, including light box 1 for imaging, camera 2 for collecting the shape of the tempered glass to be tested, high-speed computer 3 for analysis and calculation, and transmission roller for measuring and conveying the tempered glass 6-speed track speed real-time measuring device 5, said track speed real-time measuring device 5 is connected with high-speed computer 3 signals; said video camera 2 is connected with high-speed computer 3 signals; the bottom of said light box 1 has multiple rows of round holes 8, The two adjacent rows of round holes 8 at the bottom of the light box 1 are distributed at intervals, the distance between two adjacent round holes 8 in a row at the bottom of the light box 1 is 70 mm, and the distance between two adjacent rows of round holes 8 is 60 mm. The diameter of the circular hole 8 is 50 mm, and the camera 2 is a CCD camera.

[0027] When in use, the test results obtained by...

Embodiment 2

[0029] The on-line detection method for the flatness of tempered glass comprises the following steps:

[0030] 1) Install the light box 1 at the end of the tempered glass 4 production line and above the glass 4 transmission roller table; install a camera at a position corresponding to the light box 1 above the glass 4 transmission roller table;

[0031] 2) The glass 4 is conveyed at a constant speed on the glass 4 conveying roller table through the light box 1 and the camera. The round hole 8 at the bottom of the light box 1 forms a high-precision and high-brightness circular spot light curtain, and the camera continuously and high-speed photographs the light box 1 round spot during the operation of the glass 4. image, record the change of the position of each circular spot with the movement of the glass 4, and transmit the shooting signal to the high-speed computer 3;

[0032] 3) The high-speed computer 3 calculates the slope of each point on the surface of the glass 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com