Liquid purification method

A liquid purification and liquid technology, applied in chemical instruments and methods, separation methods, distillation energy recovery, etc., can solve the problems of non-recovery of heat energy, large equipment investment, and difficult treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

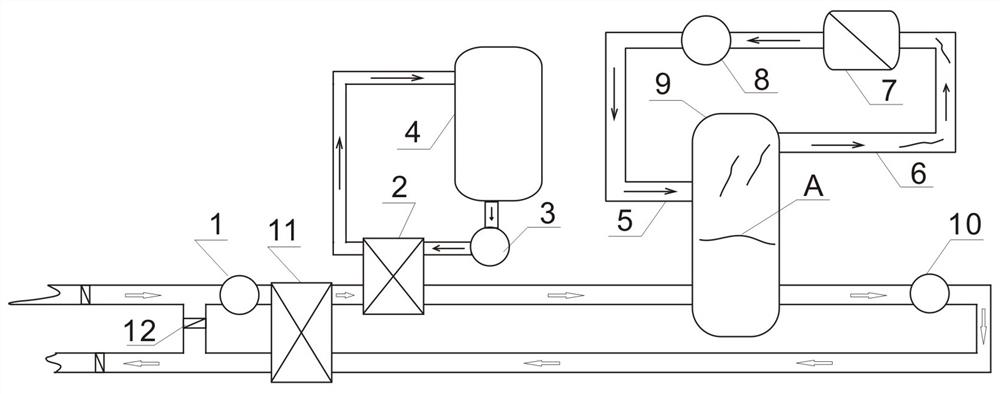

[0010] Embodiment 1. Refer to figure 1 , the first-stage temperature-rising purification equipment of the liquid purification method includes a thermal energy circulation system, a wind energy circulation system, and a liquid delivery system;

[0011] The thermal energy circulation system: the outlet of the heat source tank 4 is connected to the inlet of the thermal energy circulation pump 3 through a pipeline, the heat inlet of the heat exchanger 2 is connected to the outlet of the thermal energy circulation pump 3 through a pipeline, and the heat outlet of the heat exchanger 2 is connected through a pipeline It is connected to the inlet of the heat source tank 4, wherein the generation of heat energy of the heat source tank 4 is designed according to actual needs, and the liquid for transferring heat energy is designed according to the requirements of working conditions;

[0012] The wind energy circulation system: the outlet of the fan 8 is connected to the air inlet of the...

Embodiment approach 2

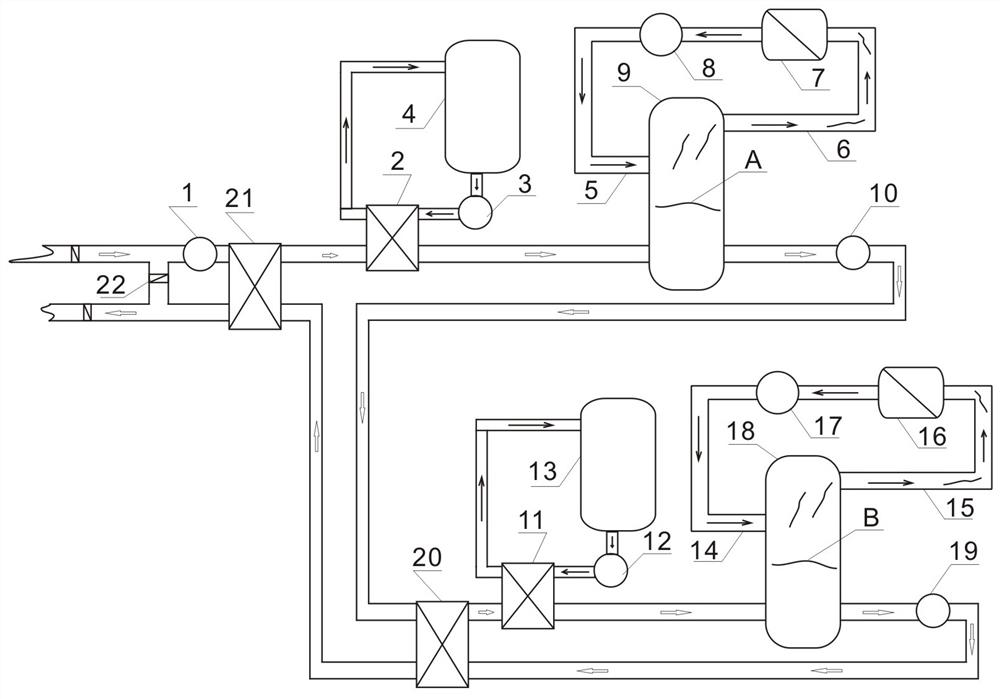

[0018] Embodiment 2. Refer to figure 2 , the multi-stage temperature-raising purification equipment of the method for liquid purification, according to the different boiling points of the purified substances, is purified by temperature-raising stages, and at least two stages have the temperature-rising temperature and purification function. Taking the 2-stage design as an example, the implementation is as follows:

[0019] The multi-stage heating purification equipment includes: a first thermal energy circulation system, a first wind energy circulation system, a second thermal energy circulation system, a second wind energy circulation system, and a liquid delivery system;

[0020] The first thermal energy circulation system: the outlet of the first heat source tank 4 is connected to the inlet of the first thermal energy circulation pump 3 through a pipeline, and the heat inlet of the first heat exchanger 2 is connected to the outlet of the first thermal energy circulation pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com