Horizontal screw centrifuge

A decanter centrifuge and isolation disc technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problem of low solid content in the light phase, inability to separate solid particles in the liquid phase, and solid content in the light phase and other problems, to achieve the effect of saving the setting of the driving source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

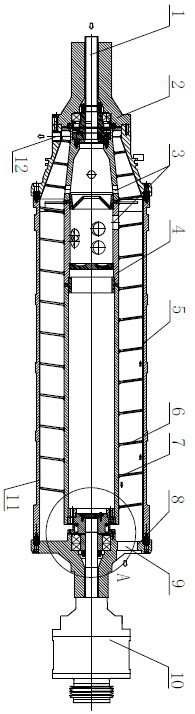

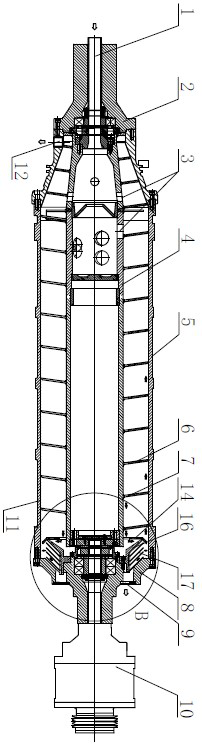

[0022] like image 3 Shown, decanter centrifuge of the present invention is in such as figure 1 On the basis of the existing decanter centrifuge shown, a disk system is added between the drum shell 5 and the inner pipe 4 near the light phase outlet 9 .

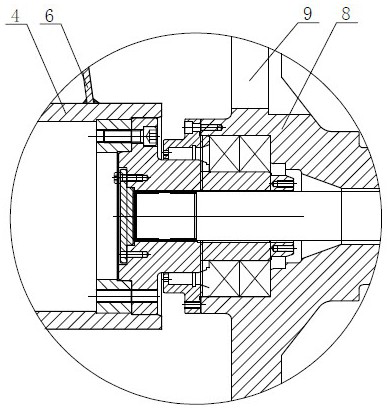

[0023] like Figure 4 As shown, the helical blade 6 at the end of the screw conveyor is near the side of the large end cap 8, and the isolation disc 14 of the disc system is arranged. The flow channel 13 is set on the side, and the flow channel 13 is a number of circular holes evenly distributed on the isolation plate 14. The light phase obtained by the decanter centrifuge enters the disc system through the flow channel 13 for secondary centrifugal separation. The other side of the isolation disc 14 has a gathering part 21 bent towards the direction of the large end cap 8. The gathering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com