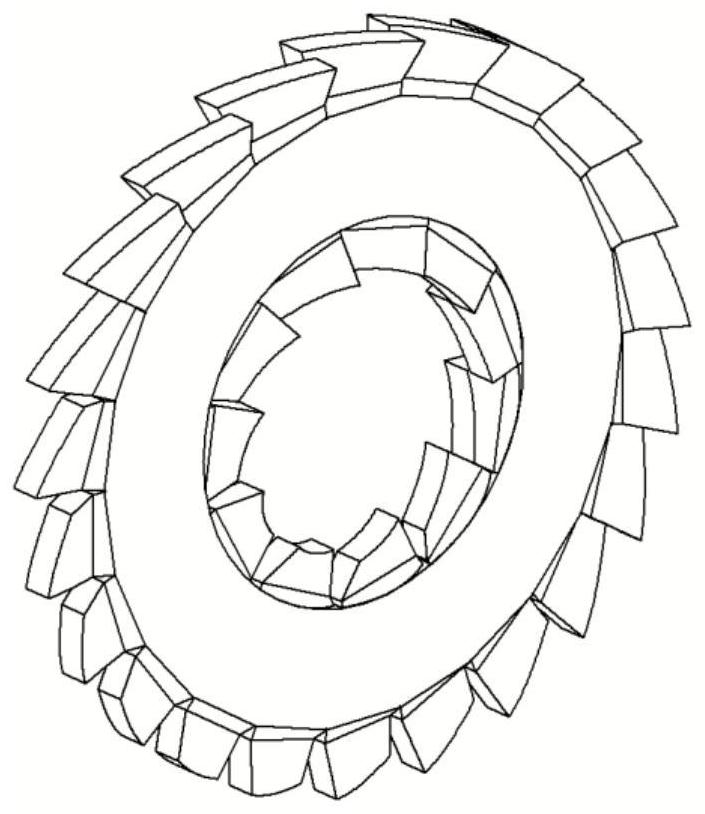

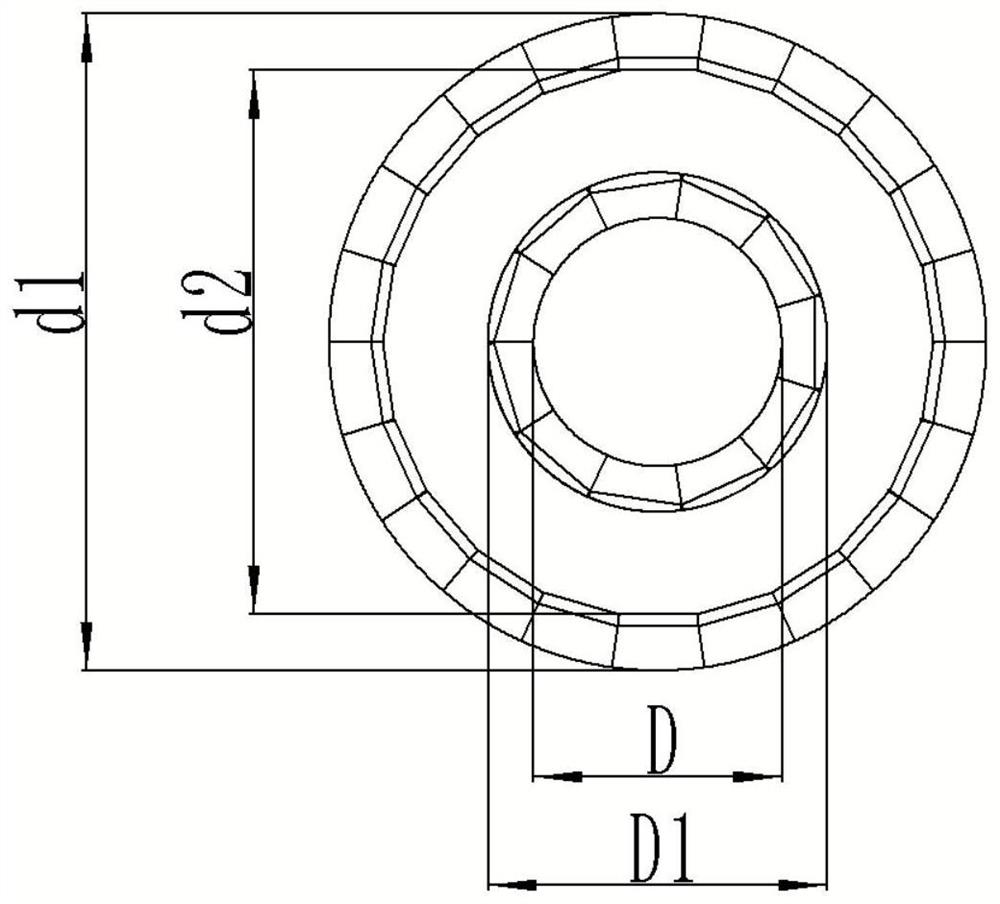

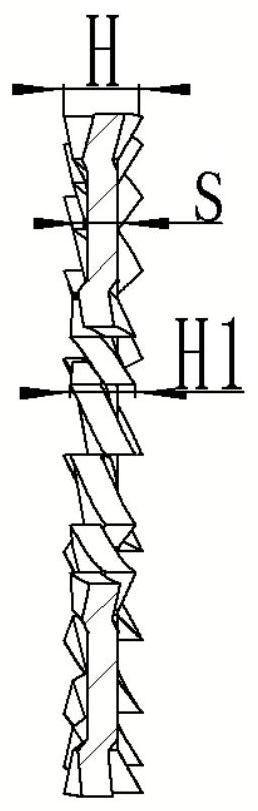

Continuous stamping die for inner and outer sawtooth locking washers

A lock washer and stamping die technology, which is applied in the field of machining tools, can solve the problems of inconvenient picking of parts, and achieve the effects of simple processing and manufacturing methods, favorable design, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solution (including the preferred technical solution) of the present invention will be further described in detail below by means of the accompanying drawings and listing some optional embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0058] The invention discloses that the invention discloses a continuous stamping die for inner and outer sawtooth lock washers, which is used for continuous stamping and forming inner and outer sawtooth lock washers. Die B, Die C for Punching Internal Teeth, Die D for Punching External Teeth, Die E for Punching External Teeth, Die F for Side Cutting and Cutting Die G.

[0059] Preferably, the positioning hole punching d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap