Constant-flow uniform-temperature heating module

A technology of heating the mold and balancing the flow, which is applied in the direction of electric heating devices, metal processing equipment, manufacturing tools, etc., and can solve problems affecting the balance of heat, the stability of the hot air circulation airflow, the weak air volume in the middle area, and the influence on the stability of the airflow, etc., to achieve Improve the effective heating range, the air flow is small, and the effect of not easy to change temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

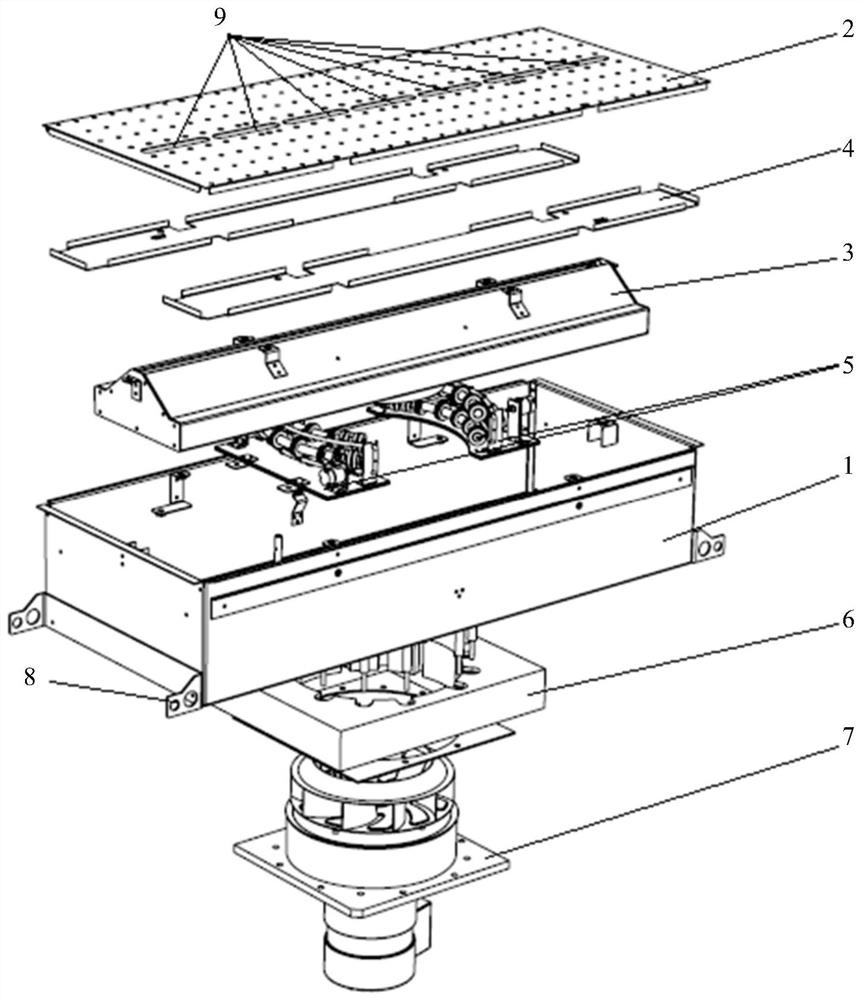

[0031] Such as figure 1 Shown is the exploded schematic view of the overall structure of the balanced flow and uniform temperature heating module of the present invention. It can be seen from the figure that the hot air perforated plate 2 is provided with a plurality of round holes arranged in an array, and the hot air perforated plate 2 blows hot air evenly across the entire surface. Product surface, heat the product. At the same time, there is a suction area in the middle of the hot air orifice plate 2, which is the suction channel of the central control suction chamber 3. The middle position below the hot air orifice plate 2 is the central control suction cavity, forming a suction cavity, and the positions on both sides are the air uniformity layer 4, which is used to balance the air flow. Below the central air suction cavity 3 is a semicircular heating wire, which is used to effectively heat the circulating air. The impeller of the blowing motor assembly 7 realizes the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com