Automatic steam curing kiln of annular automatic production line

An automatic production line and steam curing technology, which is applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of maintaining the surface humidity and temperature stability of precast concrete floors, so as to improve space utilization and maintenance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

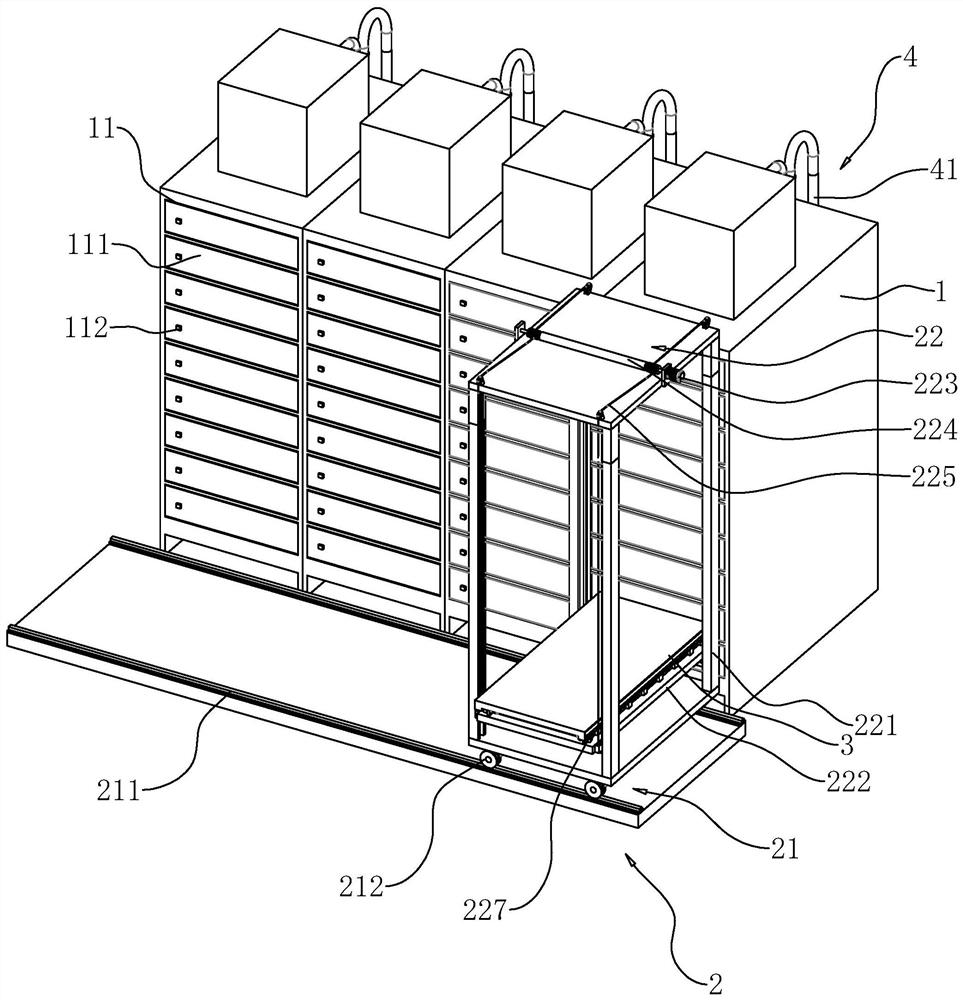

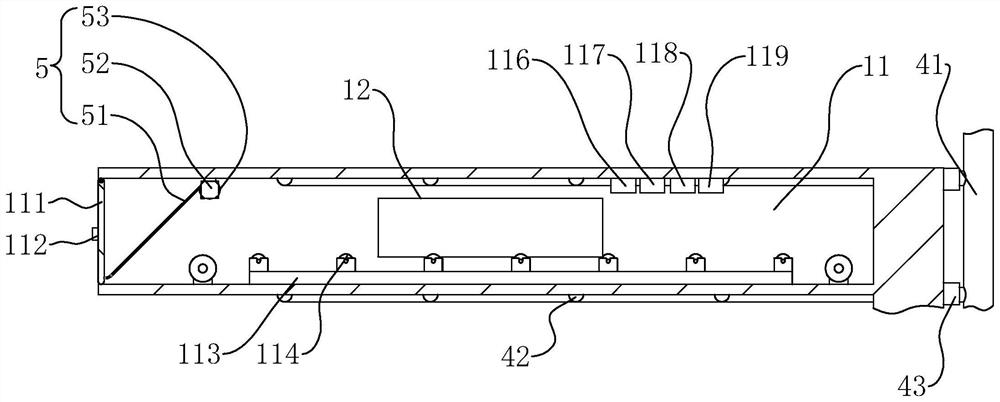

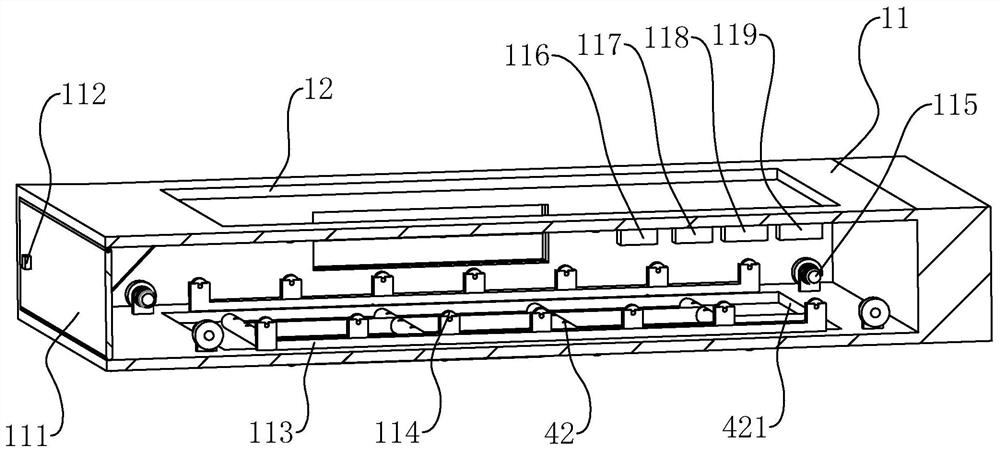

[0040] The following is attached Figure 1-8 The application is described in further detail.

[0041] After splicing molds, laying steel bars and pouring concrete on the precast concrete floor, the staff need to maintain it during the curing process of the concrete slurry of the precast concrete floor. During the maintenance process, it is necessary to ensure the temperature and The humidity is within a certain range, thereby improving the curing performance of the precast concrete floor. In the production workshop of precast concrete floors, since the curing of the concrete floors often takes several hours to dozens of hours, it needs to occupy a large amount of space in the workshop for storing and maintaining the poured concrete floors. Larger, the control and adjustment rate of temperature and humidity are slow, so the maintenance quality is not high.

[0042] The embodiment of the present application discloses an automatic steam curing kiln for a circular automatic prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com