Manufacturing method of solid waste based cementing material concrete and quantitative feeding device

A production method and concrete technology, which are applied to clay preparation devices, raw material supply devices for sale, cement mixing devices, etc., can solve problems such as high cost, affecting concrete quality, and mixing ratio deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific embodiment:

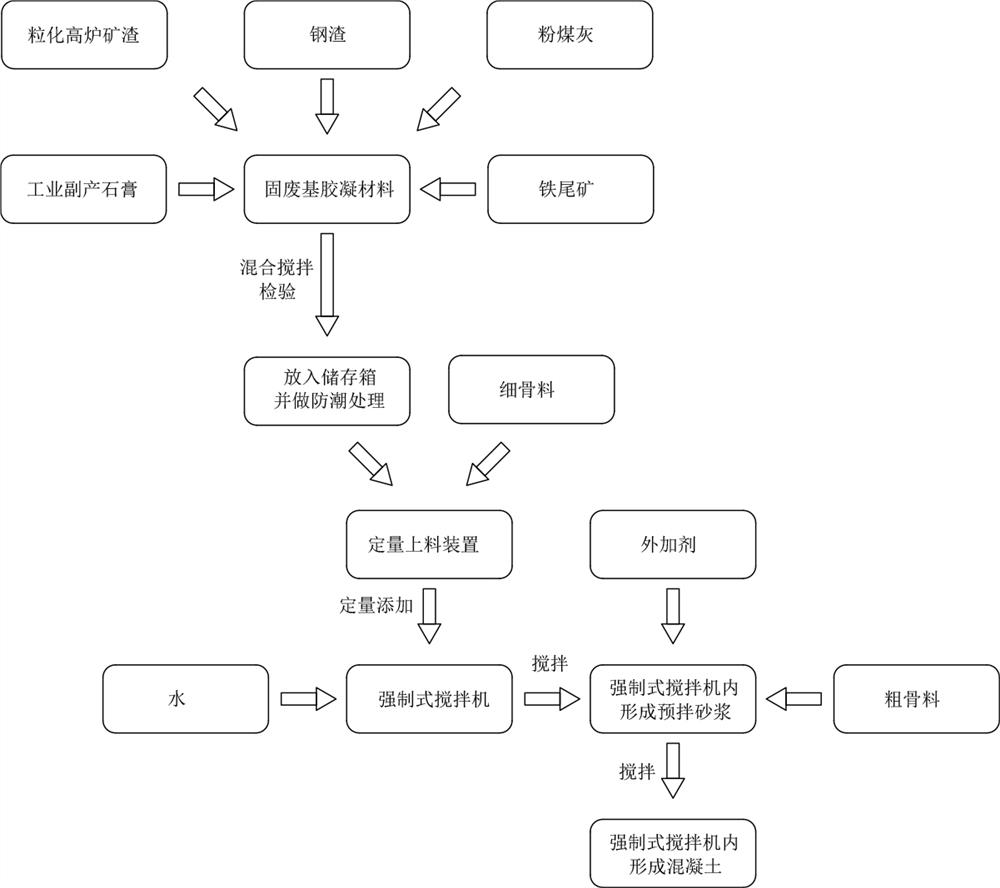

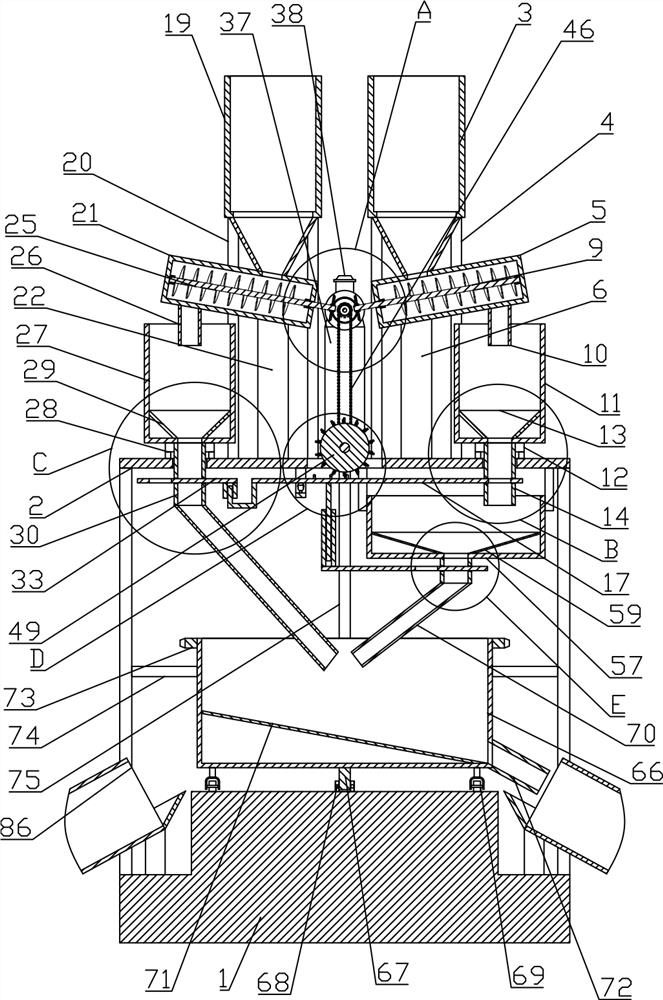

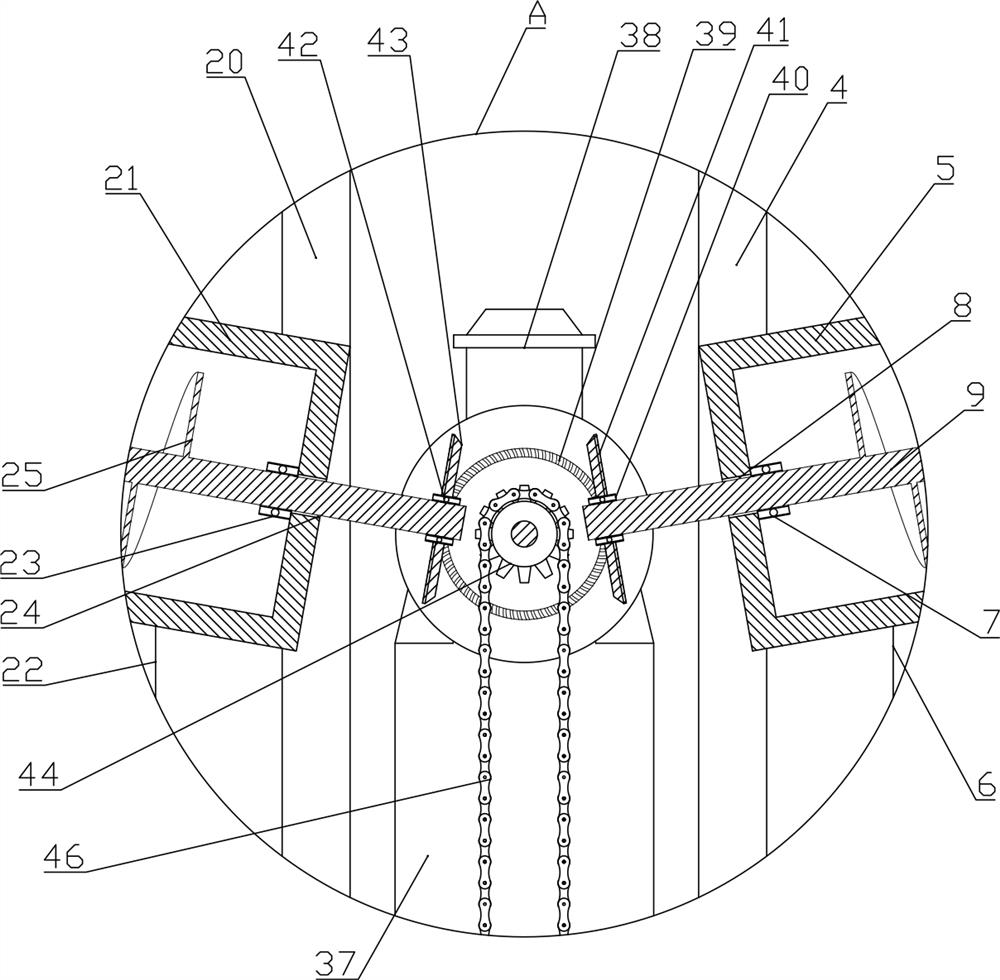

[0041]A method for making solid waste-based cementitious material concrete, comprising the solid waste-based cementitious material, the raw material ratio of the solid waste-based cementitious material is 30-60% of granulated blast furnace slag, 30-50% of steel slag, industrial by-product Gypsum 10-20%, fly ash 3-10%, iron tailings 3-10%, the processing steps include: solid waste-based cementitious material mixing, solid waste-based cementitious material inspection, solid waste-based cementitious material storage , ready-mixed mortar production, concrete production;

[0042] Step 1. Stirring of solid waste-based cementitious materials: granulated blast furnace slag, steel slag, industrial by-product gypsum, fly ash, and iron tailings are mixed in the mixing drum according to the proportion, and stirred by the agitator. At room temperature, through the excitation of divalent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com