Automatic material watching device and method under blast furnace trough

A blast furnace tank and blast furnace technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems affecting the normal work of blast furnace operators, inaccurate judgment of raw and fuel quality, and affecting physical and mental health, so as to reduce the work of looking at materials, Good material effect, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

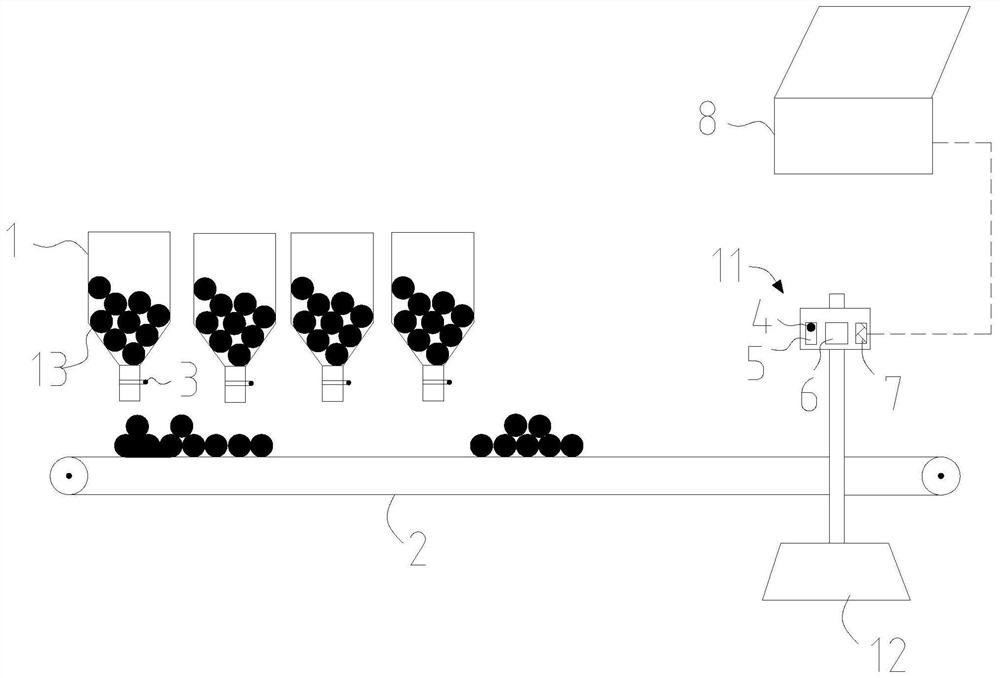

[0037] likefigure 1 As shown, the present invention is an automatic material viewing device under the blast furnace tank, and the blast furnace tank is provided with a furnace charge conveying belt 2 and a number of blast furnace raw material bins 1, and the blast furnace raw material bins 1 are arranged above the furnace charge conveying belt 2, and its innovation The advantage is that the automatic material viewing device under the blast furnace tank includes a computer 8 in the central control room, a material viewing component 11 and a number of signal emitting elements 3; When the gate of the blast furnace raw material bin 1 is opened, a signal is sent; the material viewing assembly 11 is fixedly arranged at the position behind each blast furnace raw material bin 1 above the furnace charge conveying belt 2, and is used for photographing the discharge of the blast furnace raw material bin 1 to the furnace charge conveyance The situation of the charge bar on the belt 2, whic...

Embodiment 2

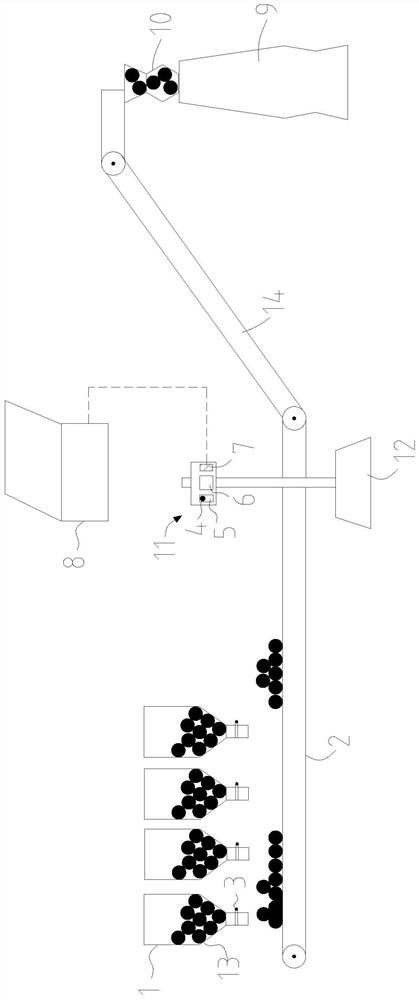

[0042] like figure 1 and figure 2 As shown, a method for checking material under a blast furnace tank of the present invention uses an automatic material checking device under a blast furnace tank described in Embodiment 1, and the furnace charge conveying belt 2 is connected with other conveying belts, and the furnace charge 13 is passed through The feeding equipment 10 is delivered to the blast furnace body 9, and the method of viewing the material is as follows:

[0043] Step 1. According to the material structure of the blast furnace, set the material type of each blast furnace raw material warehouse 1 and mark the information of each blast furnace raw material warehouse 1, and at the same time determine the discharge sequence of each blast furnace raw material warehouse 1 and the row of blast furnace raw material warehouse 1 to the furnace material conveyor belt 2. The furnace material bar on the top needs to see the position of the material;

[0044] Step 2. The opera...

Embodiment 3

[0055] Taking a certain blast furnace of a certain steel as an example, a kind of automatic material viewing device under the blast furnace trough described in Example 1 is used as an example, such as figure 1 and figure 2 As shown, there are 24 blast furnace raw material warehouses 1 in this embodiment, respectively labeled as 1-12A and 1-12B. The furnace charge conveying belt 2 is connected with other conveying belts 14, and the furnace charge 13 is sent through the feeding device 10. In the blast furnace body 9, the method of seeing material is as follows:

[0056] 1. According to the material structure of blast furnace: if ore includes sinter, pellet ore and raw ore, coke includes dry coke in new area and dry coke in old area, set the material type for 24 blast furnace raw material bins 1, and mark different blast furnace raw material bins 1 Charges used: such as 1-3A raw ore, 4-12A sintered ore, 1-5B new dry coke, 6-8B old dry coke, 9-12B pellets, and mark each blast fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com