Preparation of near-infrared reflection phosphate color pigment

A near-infrared and color technology, applied in the field of ion-doped and compounded high near-infrared reflection pigment preparation, can solve the problem of less research on colorization of aluminum phosphate pigments, and achieve high color saturation, rich colors, and even heat distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

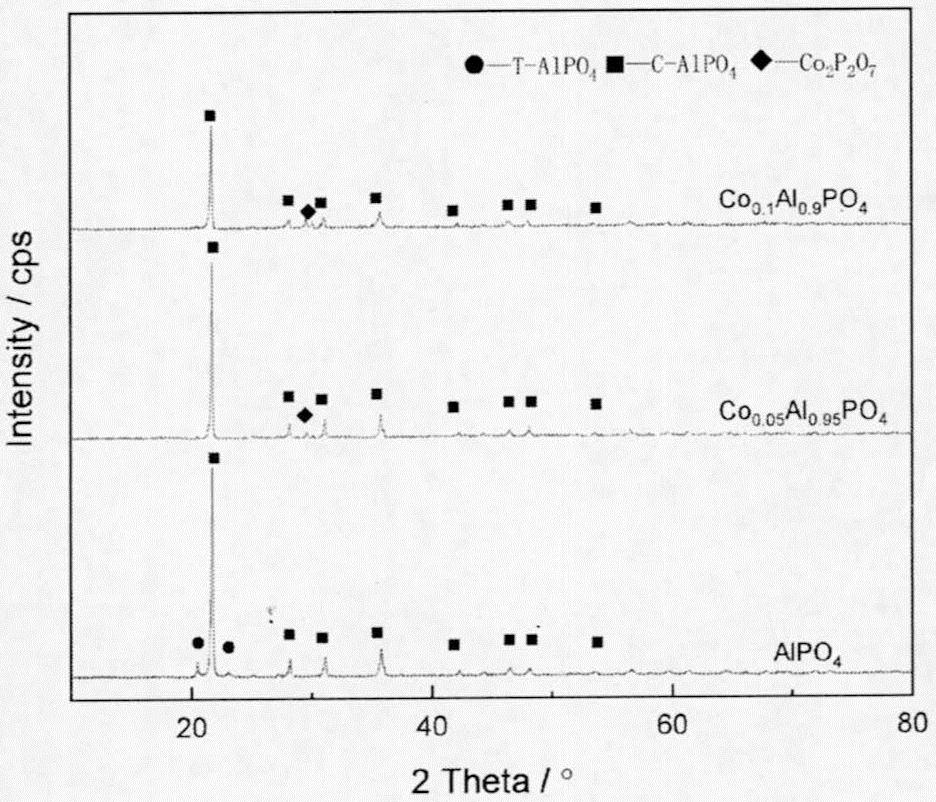

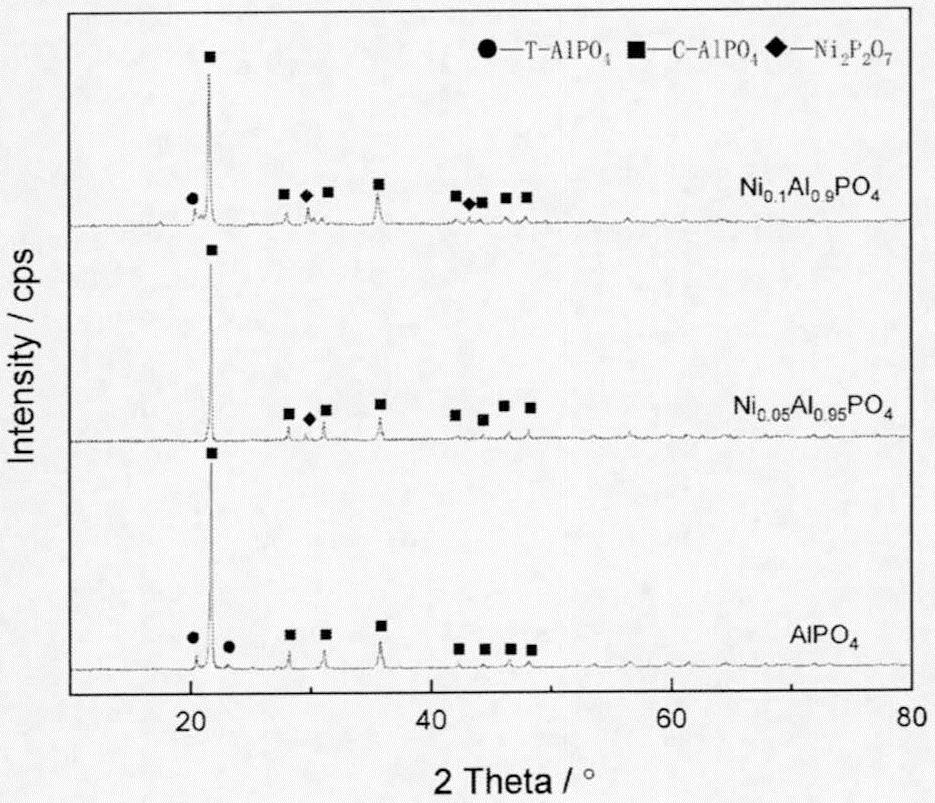

Embodiment 1

[0019]Measure 1ml phosphoric acid (purity is 85%), weigh 7.5g aluminum nitrate nonahydrate and 3.84g citric acid, all dissolve in 20ml deionized water. The above system was placed in an experimental microwave oven and stirred at a temperature of 80°C for 90 minutes to form a precursor. The precursor was transferred to a crucible, put into a muffle furnace and calcined at 1000 °C for 2 hours, and finally the product AlPO was obtained 4 .

Embodiment 2

[0021] Measure 0.02mol phosphoric acid (purity is 85%), according to molecular formula Co 0.05 al 0.95 PO 4 , Weigh cobalt nitrate and aluminum nitrate, citric acid is weighed with the equimolar amount of phosphoric acid, all dissolve in 20ml deionized water. The above system was placed in an experimental microwave oven and stirred at a temperature of 80°C for 90 minutes to form a precursor. The precursor was transferred to a crucible, put into a muffle furnace and calcined at 1000 °C for 2 h, and finally the product Co 0.05 al 0.95 PO 4 .

Embodiment 3

[0023] Measure 0.02mol phosphoric acid (purity is 85%), according to molecular formula Co 0.2 al 0.8 PO 4 , Weigh cobalt nitrate and aluminum nitrate, citric acid is weighed with the equimolar amount of phosphoric acid, all dissolve in 20ml deionized water. The above system was placed in an experimental microwave oven and stirred at a temperature of 80°C for 90 minutes to form a precursor. The precursor was transferred to a crucible, put into a muffle furnace and calcined at 1000 °C for 2 h, and finally the product Co 0.1 al 0.9 PO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com