Preparation method and preparation system of vanadium-titanium pellets

A preparation system and pelletizing technology, which is applied in the field of vanadium-titanium pellet preparation, can solve the problems such as the inability to guarantee the quality of production and the inability to improve the production capacity under the guarantee of quality, so as to achieve the effect of high output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

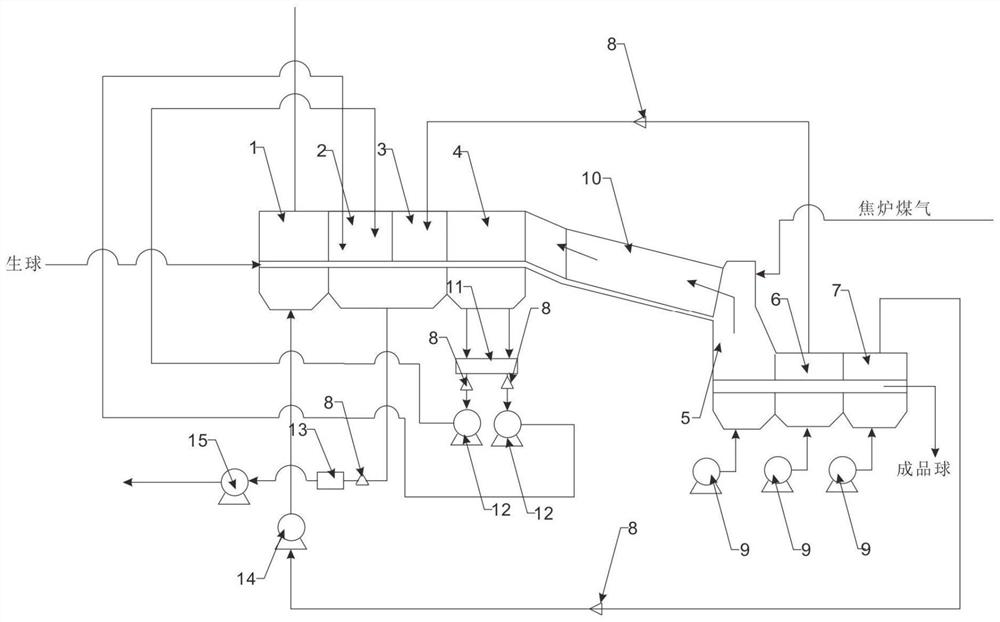

[0028]Such asfigure 1As shown, the preparation system of the vanadium-titanium pellets includes a grate machine, a rotary kiln 10 and a ring cooler which are connected in sequence.

[0029]Among them, the grate machine includes the communicating drum section 1, the exhaust section 2, the preheating section I 3 and the preheating section 4, the drum section 1 is the inlet end of the green ball, and the preheating section 4 is connected with The rotary kiln 10 is connected.

[0030]The preheating section 4 is also connected to the multi-tube dust collector 11, and the multi-tube dust collector 11 is also connected to two regenerative fans 12 at the same time. The regenerative fan 12 is connected to the exhaust section 2 at the same time; at the same time, in the regenerative fan 12 A cold air valve 8 is provided between the multi-tube dust collector 11.

[0031]In addition, the air extraction section 2 and the preheating section I 3 are in communication with the electric precipitator 13 at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com