Furnace-entering firing device with high use efficiency

A high-efficiency, furnace-feeding technology, used in furnaces, furnace types, furnace components, etc., can solve problems such as the limit of objects that cannot be processed by the grinding wheel, damage to the processed objects of the grinding wheel, trouble, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

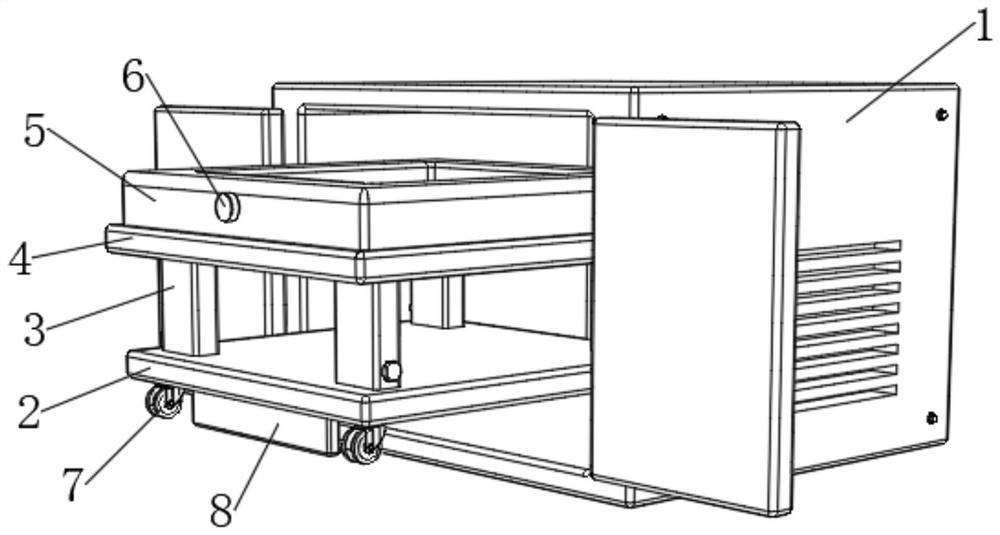

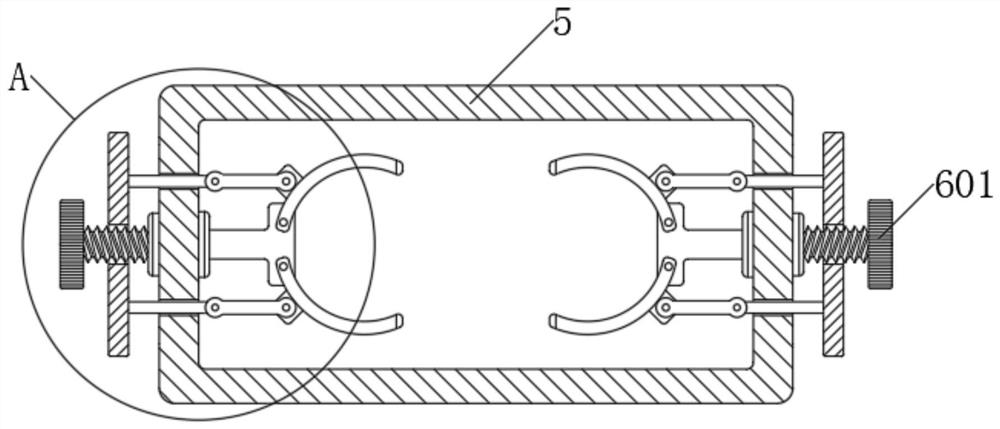

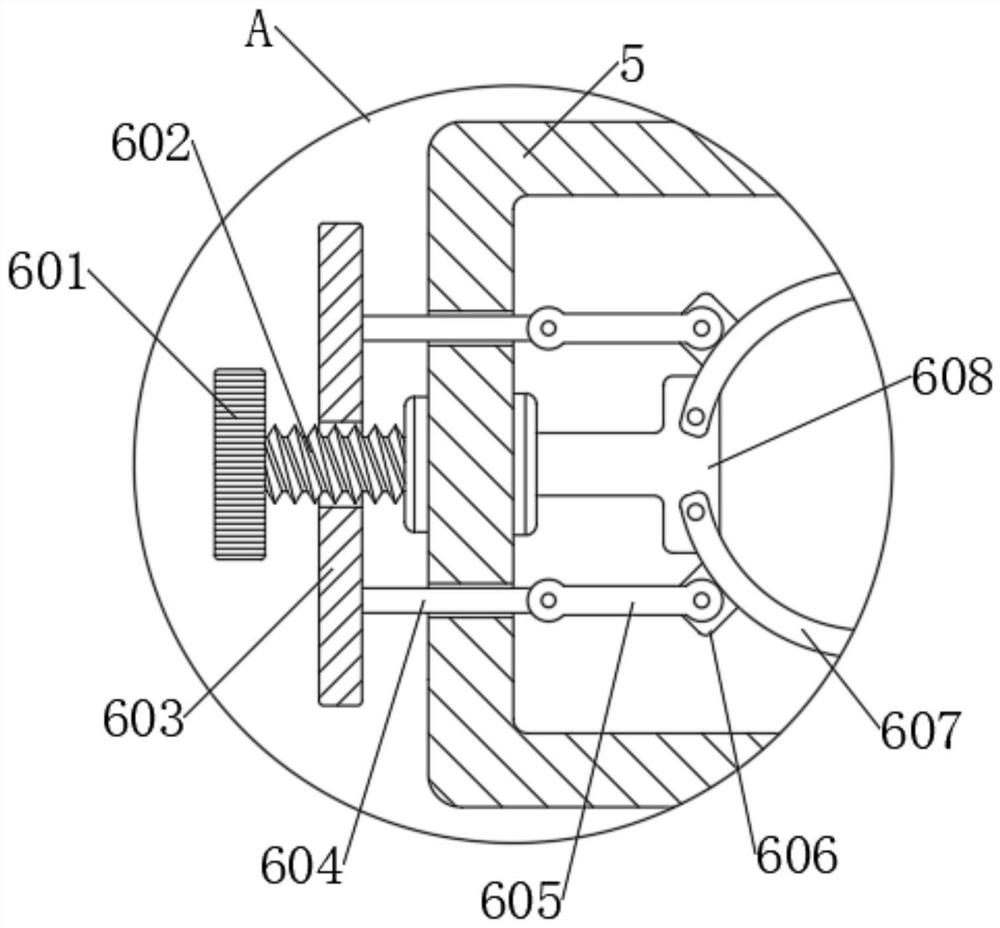

[0037] see Figure 1 to Figure 11, an embodiment provided by the present invention: a high-efficiency furnace firing device, including a cabinet body 1, a bottom plate 2, a support structure 3, a lower plate 301, a rotating shaft 302, a No. 1 helical gear 303, a No. 2 Helical gear 304, threaded rod 305, upper plate 306, slide rod 307, shock absorbing structure 4, shock absorbing box 401, fixed block 402, No. 1 spring 403, No. 1 ear seat 404, telescopic guide rod 405, No. 2 ear seat 406, installation box 5, limit mechanism 6, knob 601, screw rod 602, installation block 603, No. 1 connecting rod 604, No. 2 connecting rod 605, connecting block 606, arc clamping rod 607,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com