Heterogeneously integrated thermal infrared sensing element and thermal infrared sensor

A technology of heterogeneous integration and sensing elements, applied in the direction of electric radiation detectors, instruments, measuring devices, etc., can solve the trouble of making array elements and the inability to configure circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above content of the present invention more comprehensible, preferred embodiments are specifically cited below, together with the accompanying drawings, and described in detail as follows.

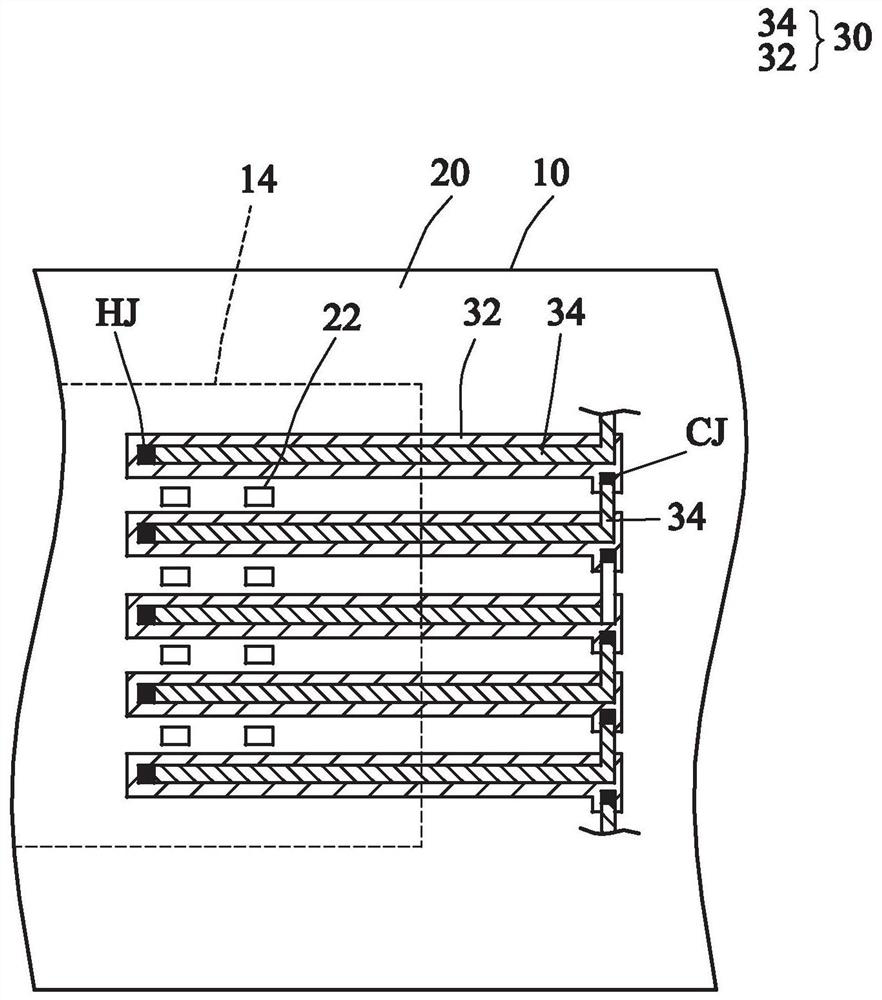

[0035] The spirit of the present invention is to use the technology of heterogeneous integration, first use the integrated circuit (especially CMOS) front-end process to form a circuit (including multiple metal layers) in the wafer, and then define the circuit on the wafer in the back-end process. A groove or cavity or predetermined sacrificial layer structure. Then use wafer bonding technology to bond the two wafers together, and then perform material removal, patterning and wiring processes to manufacture thermal infrared sensing elements or thermal infrared sensors (array elements).

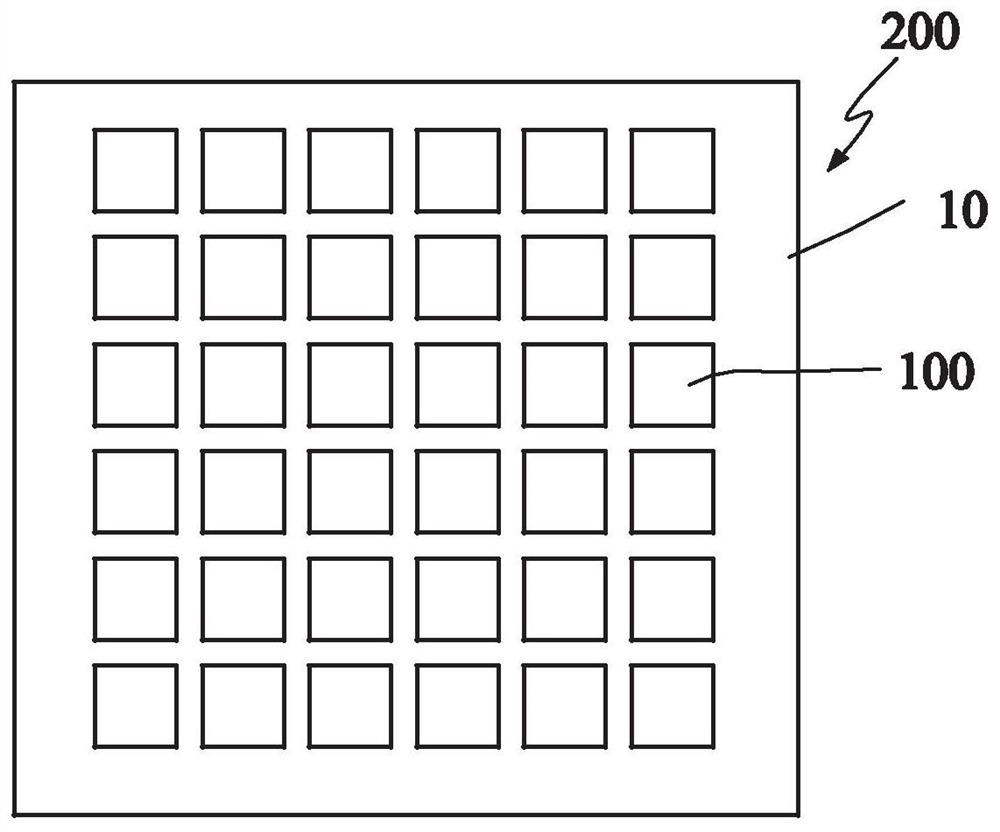

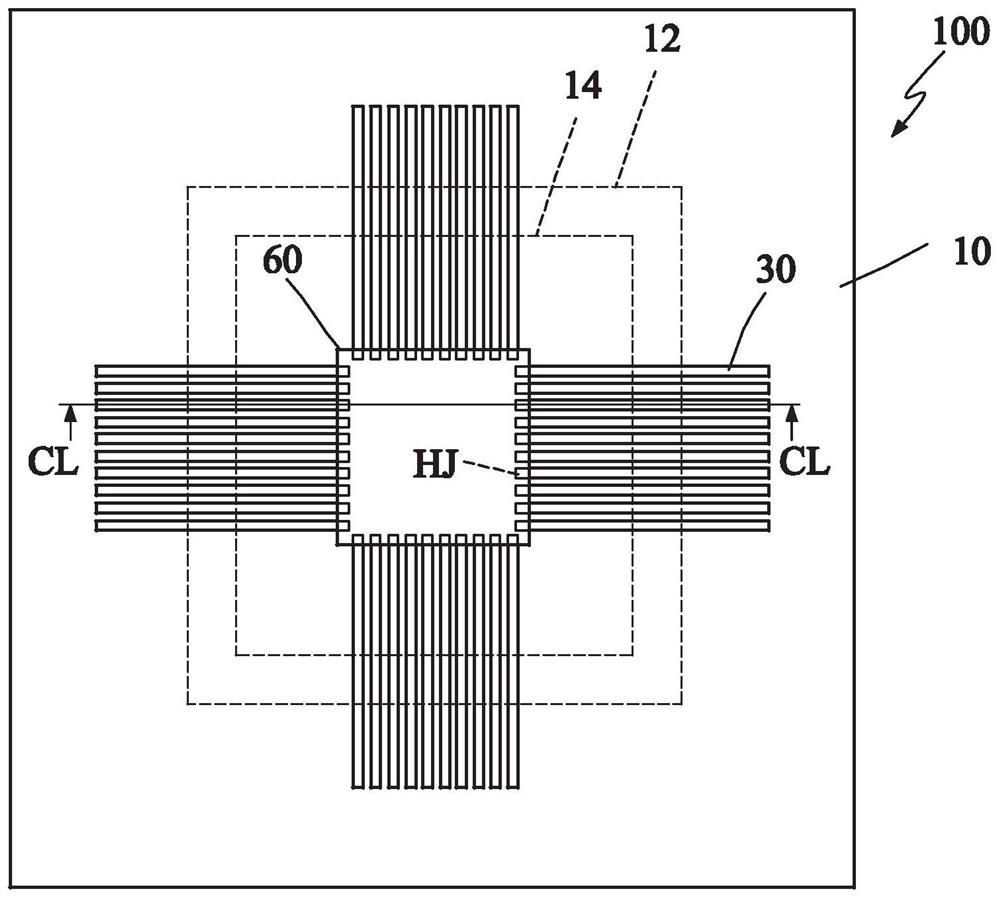

[0036] Figure 1A A schematic top view of a thermal infrared sensor according to a preferred embodiment of the present invention is shown. Such as Figure 1A As shown, a therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com