Machined part surface vibration line defect detection method

A defect detection and parts technology, applied in computer parts, instruments, design optimization/simulation, etc., can solve problems such as low detection accuracy of surface chattering defects and parameter drift of flutter detection model, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

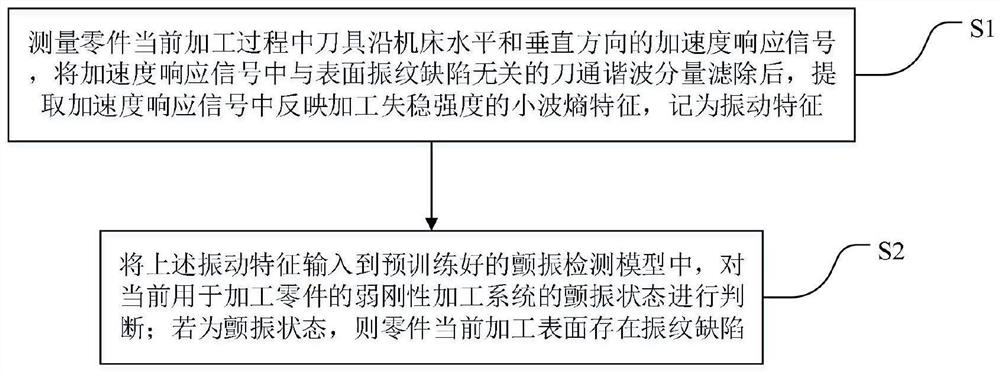

[0031] A method for detecting vibration marks on the surface of a machined part, such as figure 1 shown, including the following steps:

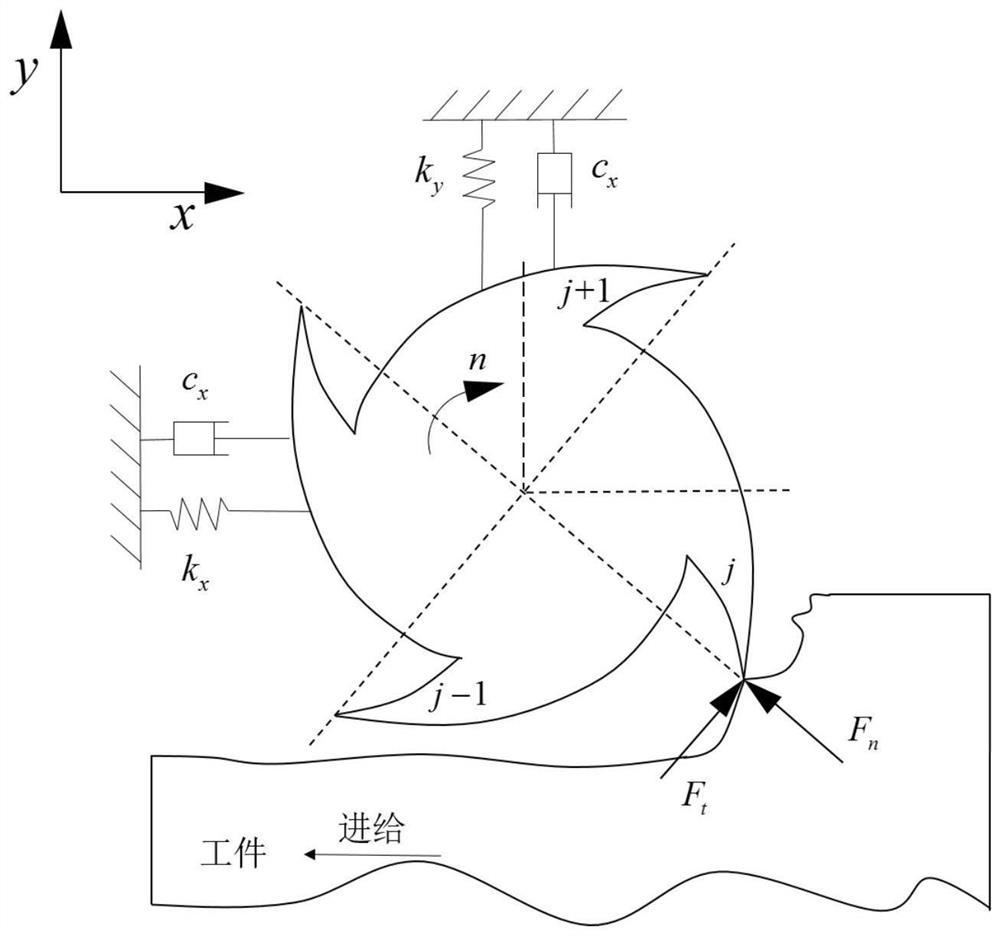

[0032] S1. Measure the acceleration response signal of the tool along the horizontal and vertical directions of the machine tool during the current processing of the part, filter out the tool pass harmonic component in the acceleration response signal that is not related to the surface vibration defect, and extract the processing instability reflected in the acceleration response signal The wavelet entropy feature of intensity is denoted as vibration feature;

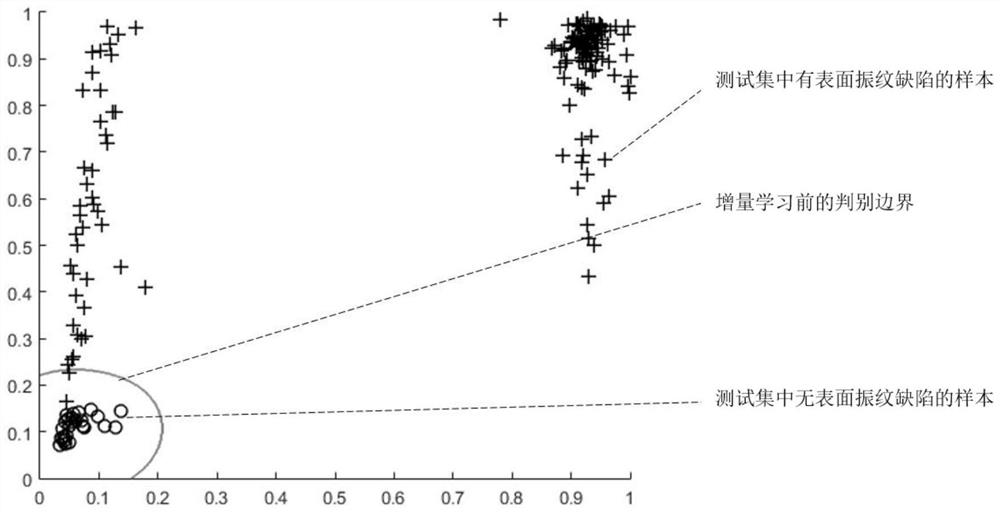

[0033] S2. Input the above vibration characteristics into the pre-trained chatter detection model, and judge the chatter state of the weakly rigid processing system currently used to process parts; if it is in the chatter state, there are chatter marks on the current processing surface of the part defect;

[0034] Wherein, the flutter detection model is a machine learning model; in ...

Embodiment 2

[0075]A computer-readable storage medium, the computer-readable storage medium includes a stored computer program, wherein when the computer program is run by a processor, the device where the storage medium is located is controlled to perform the processing provided in Embodiment 1 of the present invention Method for detection of vibration marks on the surface of parts. The relevant technical solutions are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com