7T global shutter pixel structure based on semi-floating gate

A global shutter, pixel structure technology, applied in image communication, color TV components, TV system components and other directions, can solve the problems of small fill factor, large fill factor, low readout noise, etc., to achieve high global Shutter efficiency, high pixel fill factor, thermal noise removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further clarify the purpose, technical solutions and advantages of the present invention, specific implementations of the present invention are given below in conjunction with examples. In this instance:

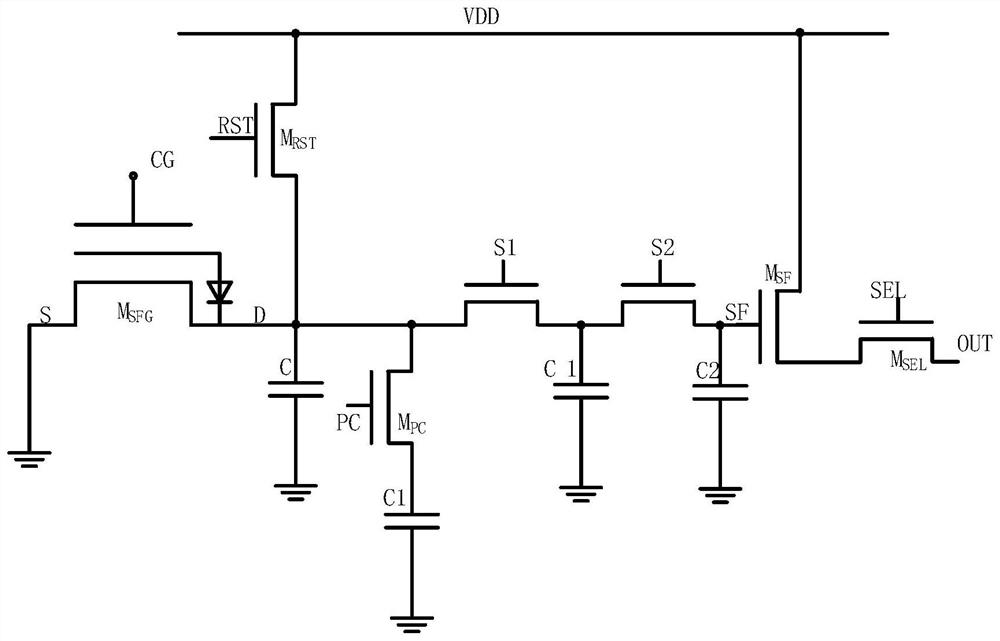

[0012] Semi-floating gate device M SFG Using NMOS tube, the width-to-length ratio is (1.2μm) / (6μm); the switch tube M PC Using NMOS tube, the width to length ratio is (4μm) / (5μm); reset tube M RST Using NMOS tube, the aspect ratio is (4μm) / (0.35μm); source follower M SF Using NMOS tube, the width to length ratio is (4μm) / (6μm); select tube M SEL Using NMOS tube, the width-to-length ratio is (4μm) / (5μm); the switch tube M S1 and M S2 They all use NMOS tubes with a width-to-length ratio of (4μm) / (5μm); capacitors C1 and C2 both use MOS capacitor structures with a capacitance value of 4fF.

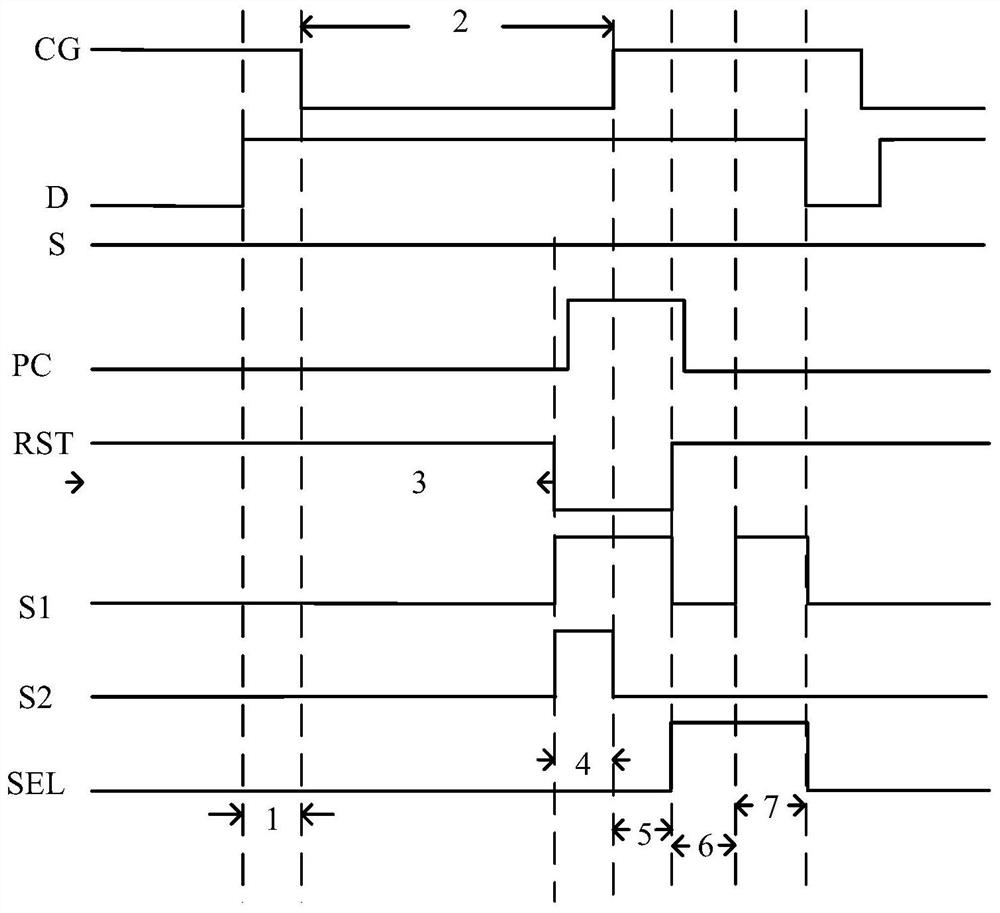

[0013] In timing design, the high level is 3.3V, and the low level is 0V. In the timing design part, the parameters of an exposure cycle are designed as follows: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com