A kind of preparation method of nitrogen-doped mof-like structure modified two-phase sulfide material

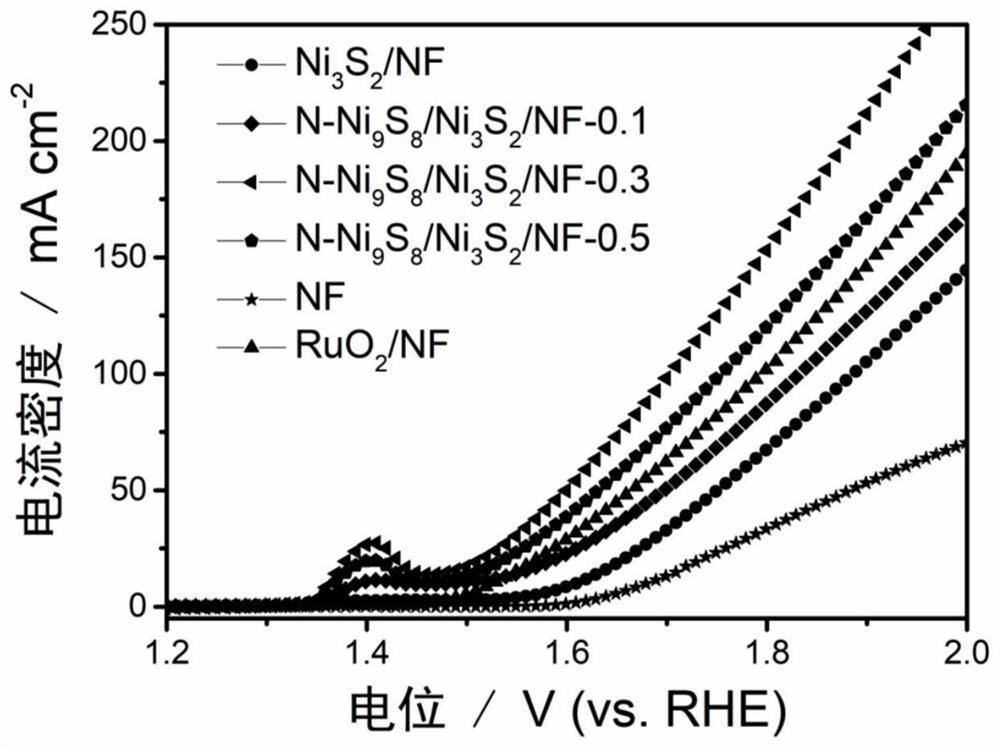

A technology of nitrogen doping and sulfide, applied in the field of electrocatalysis, can solve the problems of easy collapse of catalytic structure and long reaction cycle, achieve high specific surface area, good conductivity, and improve the performance of electrocatalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

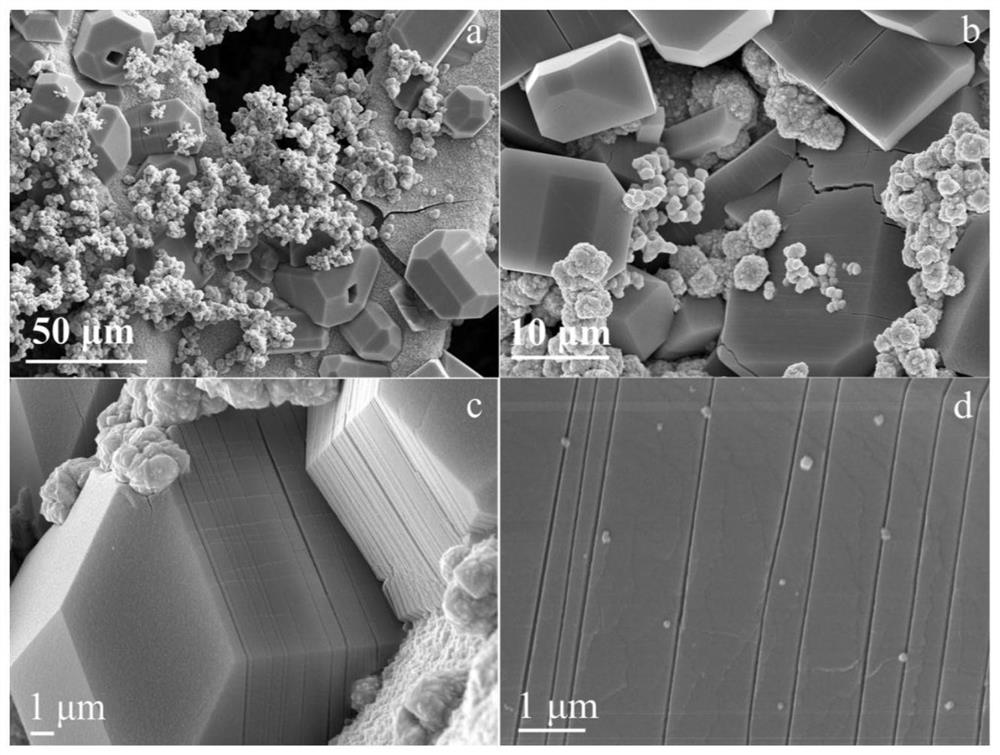

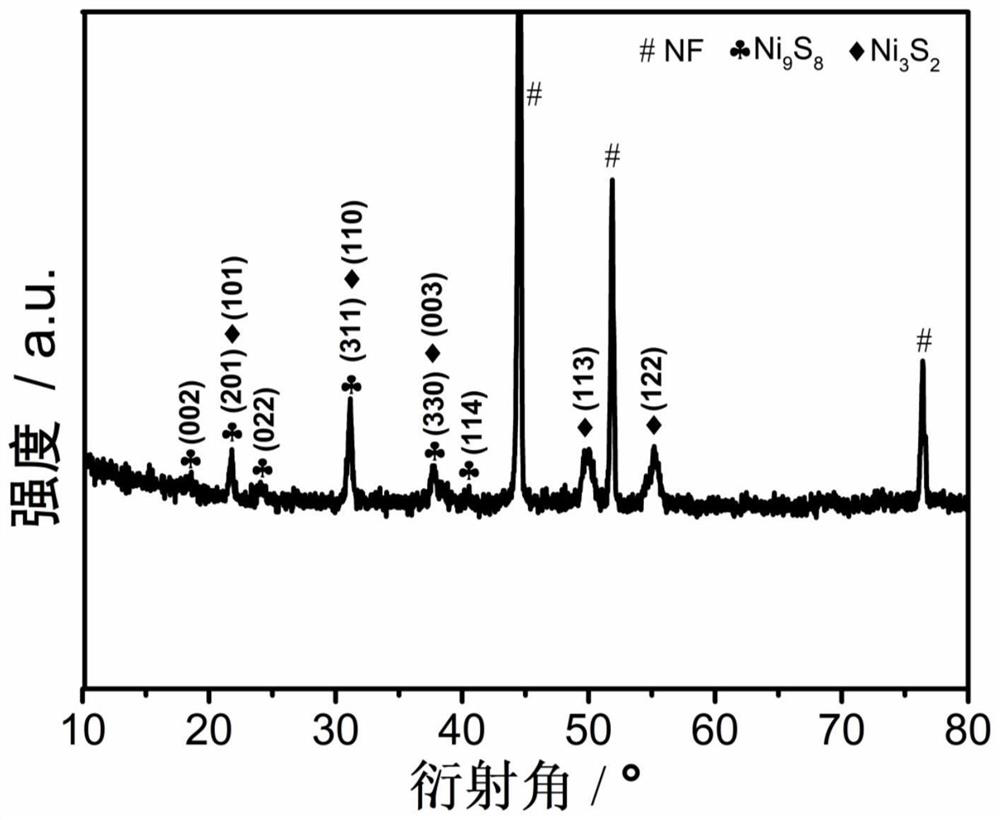

[0028] The cut-out Ni metal foam (NF, 1cm×2cm) was ultrasonically cleaned with 3M hydrochloric acid, acetone, water and ethanol for 10min, and vacuum-dried at 60°C for 6h before use. Weigh 0.3mmoL NiCl 2 6H 2 O was dissolved in 25 mL of ethylene glycol to obtain solution A. Dissolve 1.0mmoL thiourea in 25mL ethylene glycol solvent to obtain solution B. Add solution B dropwise to solution A, stir well and mix well. Then the mixed solution was transferred to a high-pressure reactor, and at the same time, one piece of the above-mentioned clean and dry NF was vertically put into a sealed high-temperature reactor. Finally, the reaction kettle was put into an oven, and the reaction temperature was controlled at 160°C. After solvothermal reaction for 8 hours, the reaction kettle was taken out and cooled naturally. The product was washed repeatedly with deionized water and ethanol, and dried in a vacuum oven at 60°C for 12 hours to obtain N-Ni 9 S 8 / Ni 3 S 2 / NF (see figure ...

Embodiment 2

[0030] Embodiment 2 is similar to embodiment 1, and substrate is dense nickel sheet (NP) among embodiment 2, and gained electrode is N-Ni 9 S 8 / Ni 3 S 2 / NP (see Figure 4 In part a), compared to the Ni metal foam substrate in Example 1, Ni 9 S 8 There are few crystal phases, most of the material is spherical Ni 3 S 2 , indicating that the radius of curvature and porous structure of the metal substrate are conducive to the occurrence of crystal phase transformation.

Embodiment 3

[0032] Embodiment 3 is similar to embodiment 1, and nickel salt is a kind of in nickel acetate, nickel sulfate, nickel nitrate in embodiment 3, obtains N-Ni 9 S 8 / Ni 3 S 2 / NF, indicating that different types of nickel salt precursors can assist in the completion of crystal phase transformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com