Ultrasonic metal powder manufacturing equipment

A metal and ultrasonic technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of unguaranteed consistency of finished products, uncontrollable particle production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

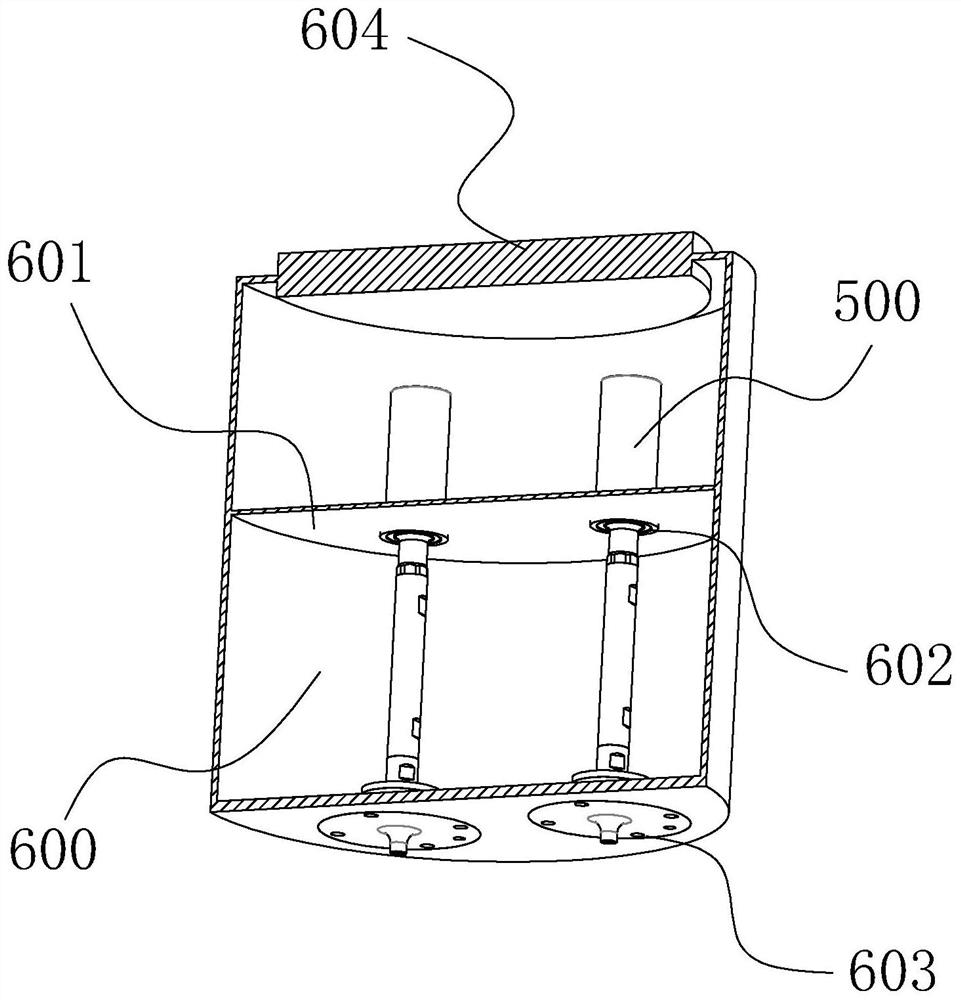

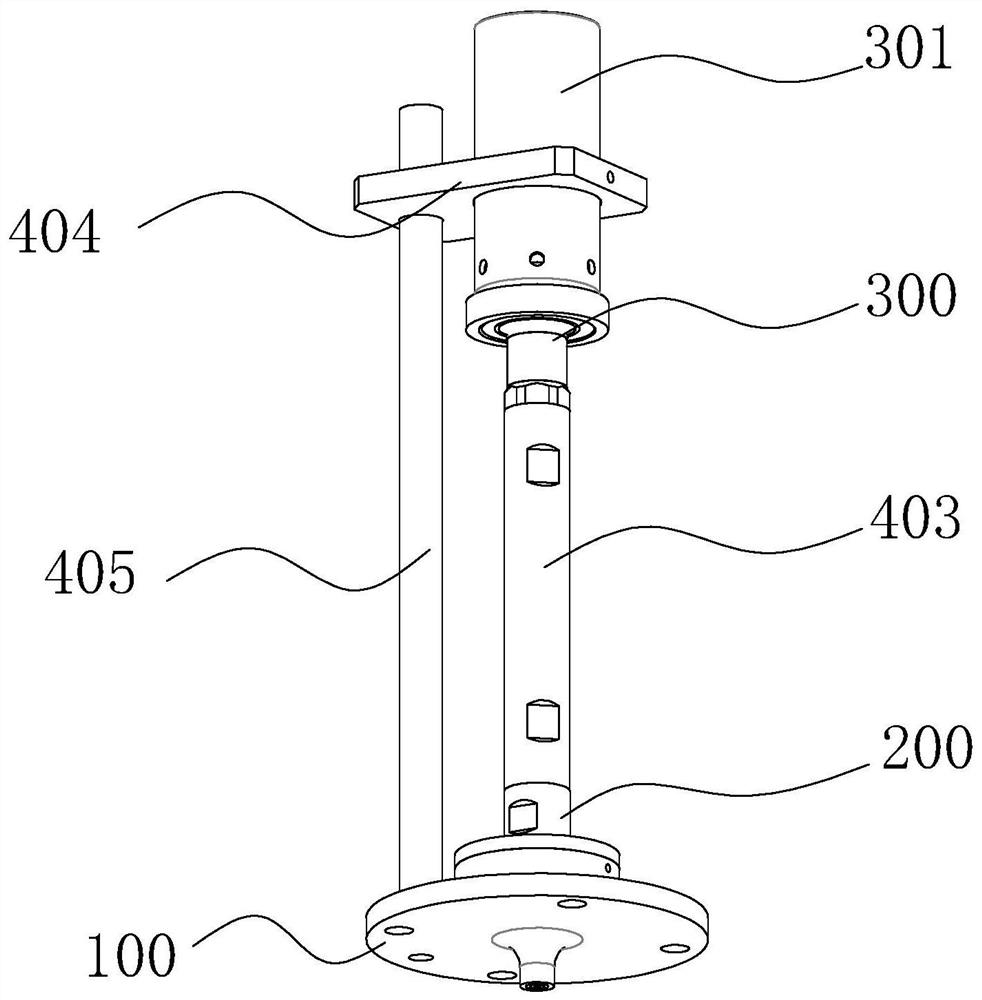

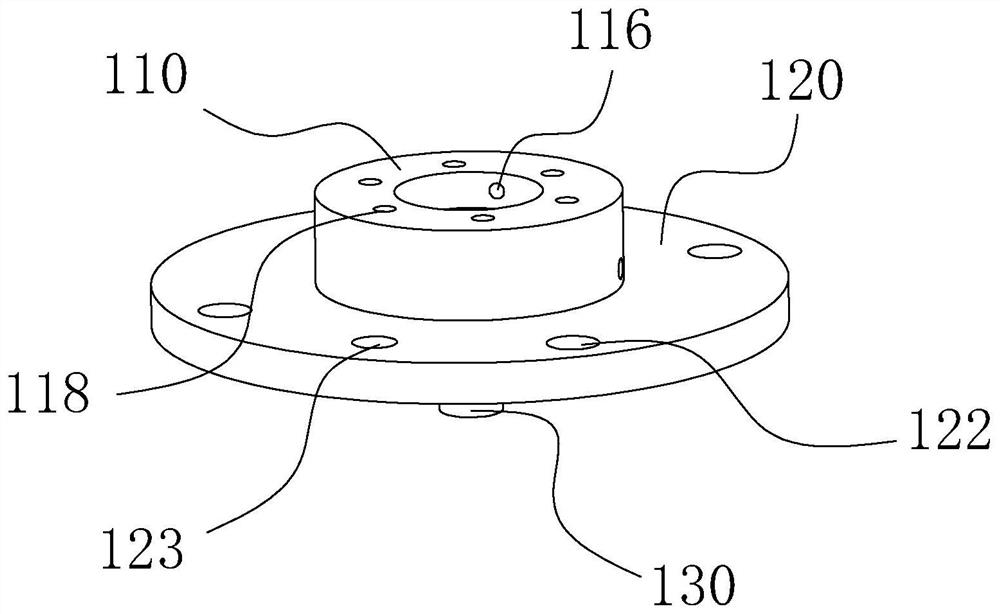

[0026] An ultrasonic metal powder making equipment, comprising a blowing hood 100 and a tool head 200, characterized in that the tool head 200 is installed in the blowing hood 100, a transducer 300 is arranged above the tool head 200, and the blowing hood 100 Including a tool head seat 110 , a blowing disc 120 and an air outlet 130 , the tool head 200 includes a shock-guiding joint 210 , a sealing layer 220 and a liquid outlet 230 .

[0027] In this embodiment, the shock guide joint 210 is a solid cylinder, and the upper end surface of the shock guide joint 210 is provided with an extension rod installation hole 211, and the depth of the extension rod installation hole 211 is half of the length of the shock guide joint 210. One is to enhance the conduction effect of sound waves and reduce the energy loss in conduction.

[0028] In this embodiment, the sealing layer 220 is also a solid cylinder, the diameter of the sealing layer 220 is larger than that of the shock-guiding join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com