Natural gas pipeline cut-off notch polishing equipment

A technology for natural gas pipelines and equipment, used in grinding/polishing equipment, metal processing equipment, grinders, etc., can solve the problems of difficult and uniform grinding, low grinding efficiency, and difficult to remove, and achieve convenient grinding, improve efficiency, and facilitate positioning and fixing. and polished effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

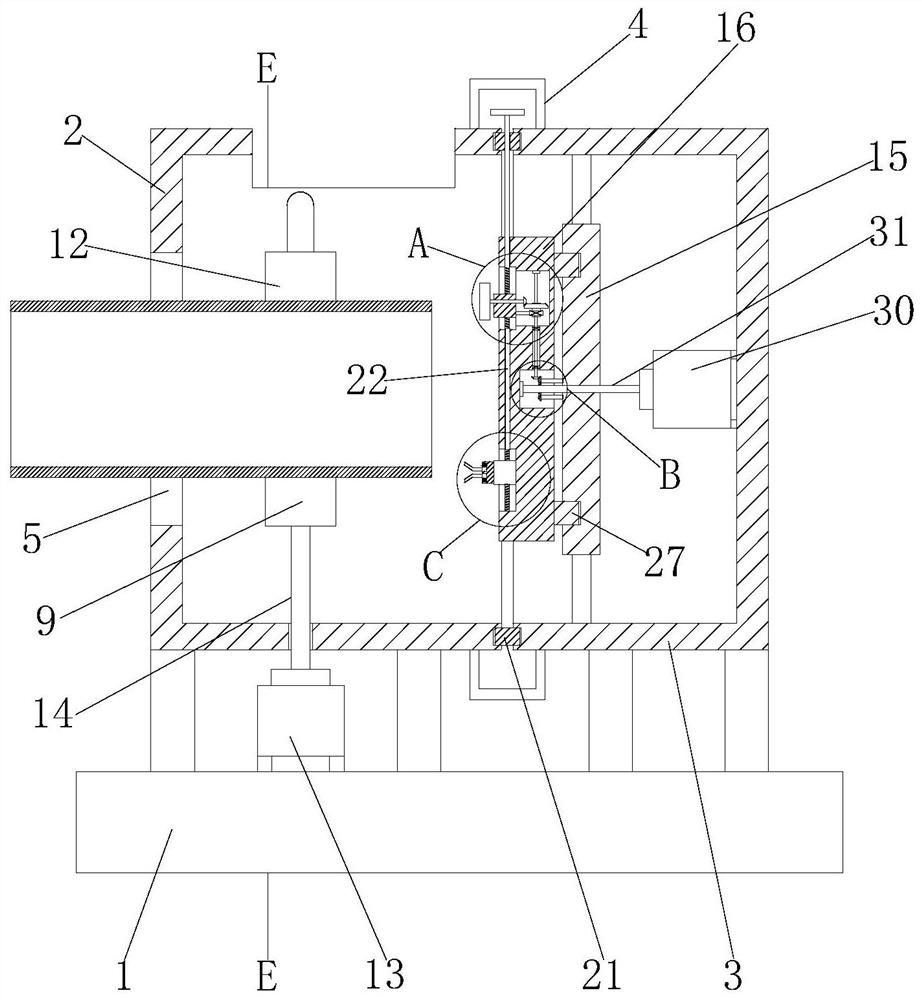

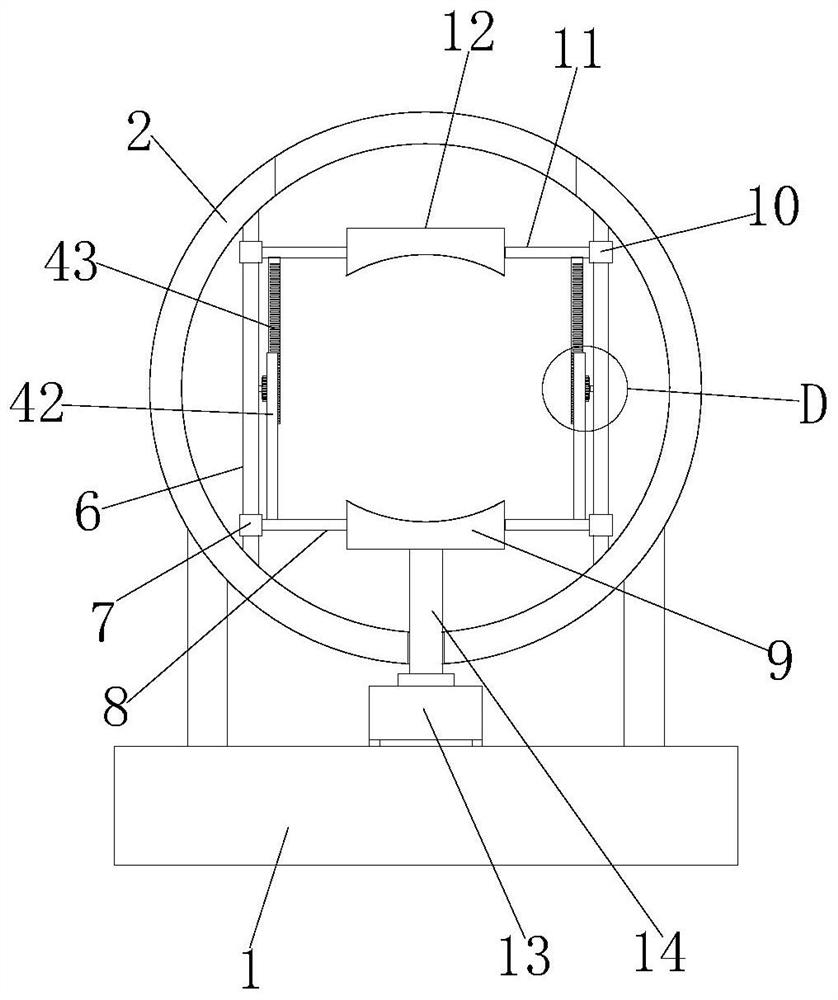

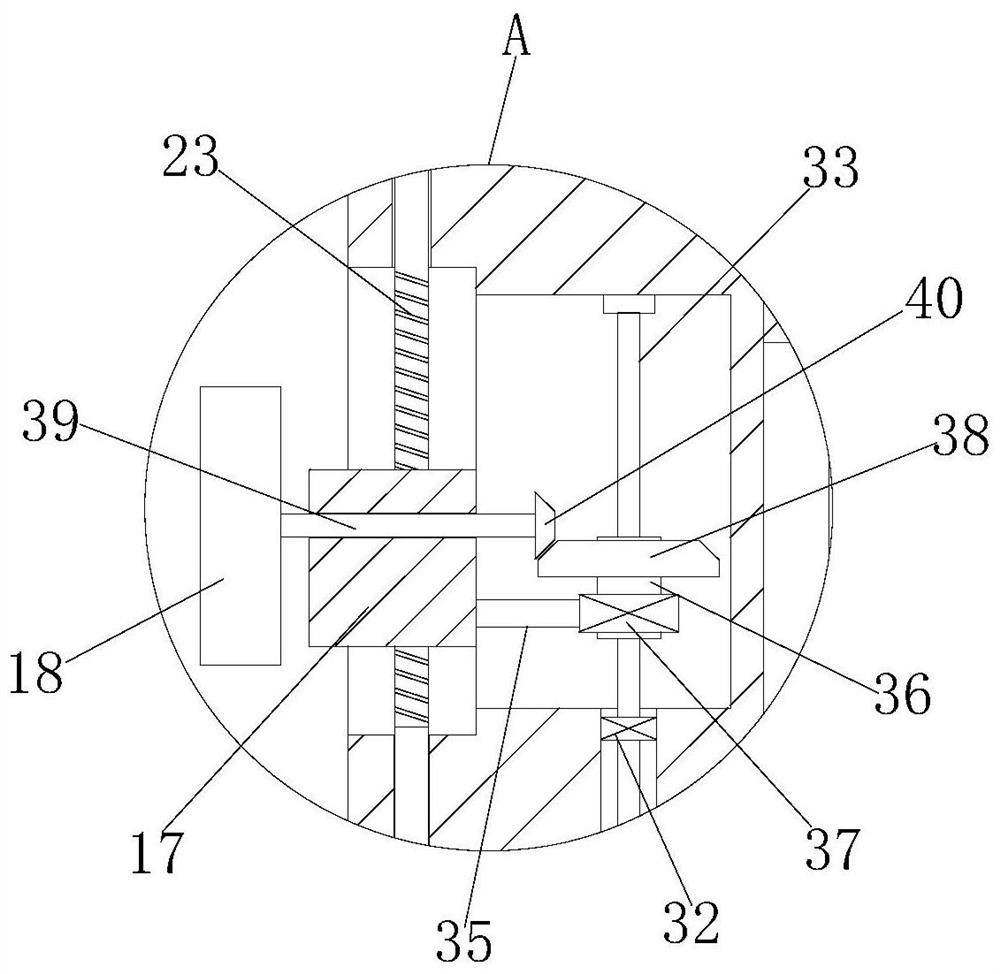

[0030] refer to Figure 1-6, a natural gas pipeline truncation mouth grinding equipment, including a base 1, a first shell 2 and a second shell 3, the first shell 2 and the second shell 3 are fixed on the top of the base 1, the first shell The right side of 2 and the left side of the second housing 3 are provided with openings, and the first housing 2 and the second housing 3 are jointly connected with a plurality of U-shaped connecting rods 4, and the left side of the first housing 2 is opened. There is a feed port 5, and two first sliding bars 6 are fixedly installed in the first housing 2, and the first sliding blocks 7 are slidingly sleeved on the two first sliding bars 6, and the two first sliding blocks 7 are provided with Both are fixedly connected with a first connecting rod 8, and one end of the two first connecting rods 8 close to each other is fixedly connected with the same lower arc-shaped block 9, and the first sliding rod 6 is slidingly sleeved with a second sli...

Embodiment 2

[0041] refer to Figure 1-6 , a natural gas pipeline truncation opening grinding equipment, including a base 1, a first shell 2 and a second shell 3, the first shell 2 and the second shell 3 are fixedly installed on the top of the base 1 by welding, the first The right side of the housing 2 and the left side of the second housing 3 are provided with openings, and the first housing 2 and the second housing 3 are jointly connected with a plurality of U-shaped connecting rods 4, and the left side of the first housing 2 There is a feed port 5 on the side, and two first sliding rods 6 are fixedly installed in the first housing 2 by welding. The first sliding blocks 7 are slidingly sleeved on the two first sliding rods 6, and the two first The slider 7 is fixedly connected with the first connecting rod 8 by welding, and the ends of the two first connecting rods 8 close to each other are fixedly connected with the same lower arc-shaped block 9 by welding, and the first sliding rod 6 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap