Rubber asphalt concrete

A rubber asphalt and concrete technology, applied in the field of rubber asphalt concrete, can solve the problems of poor high temperature storage stability and poor comprehensive road performance of rubber asphalt concrete, and achieve the effects of improving performance, good compatibility and improving compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

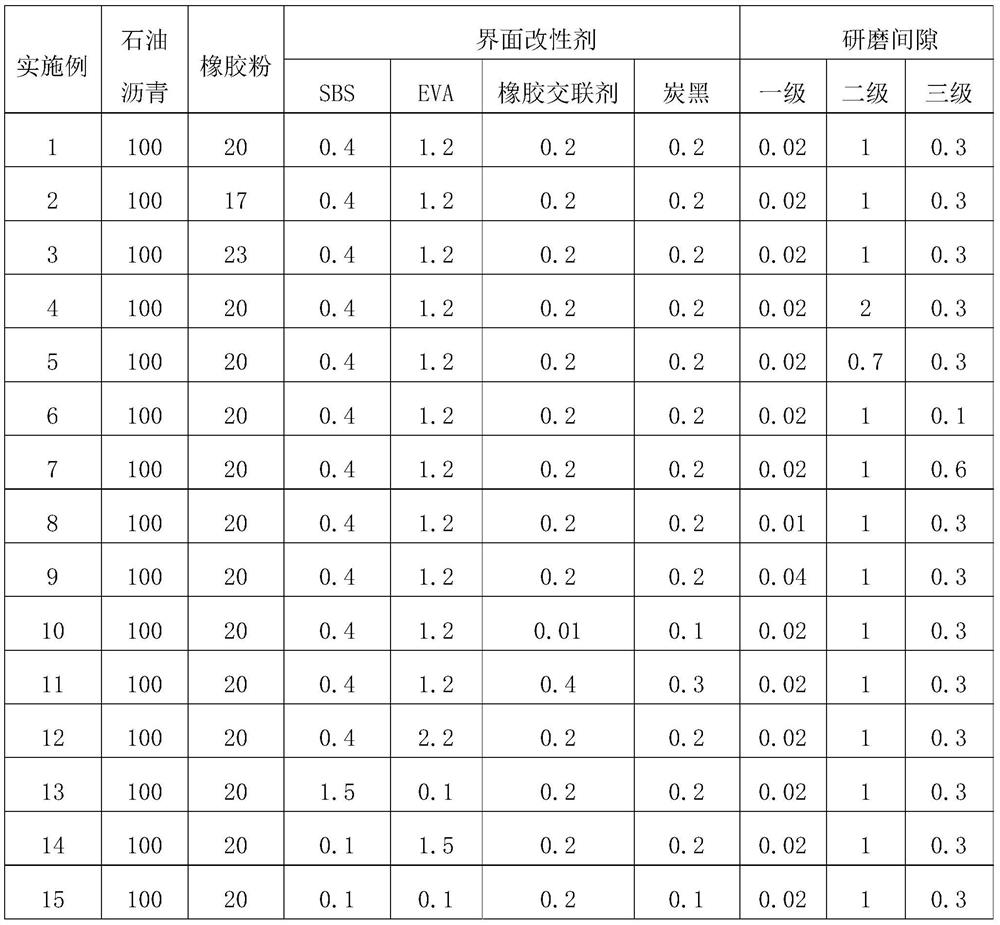

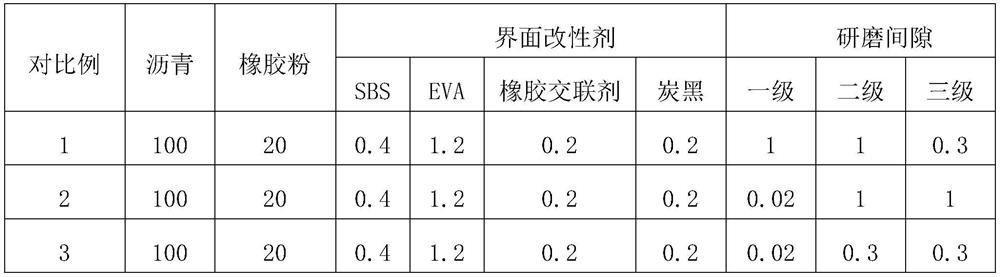

Examples

preparation example Construction

[0050] The preparation method of interfacial modifier, comprises the following steps:

[0051] In step 1, the SBS is crushed and sieved, and the SBS powder with a particle size of 40-120 mesh is selected for use.

[0052] Step 2: put the EVA and crushed SBS powder into the hopper of the extruder according to the metering, mix and melt them at a temperature of 140-190°C, and introduce them into the second-stage extruder.

[0053] Step 2: put rubber cross-linking agent and carbon black into the two-stage extruder according to metering, mix and melt at a temperature of 140-190° C., extrude, cool, and pelletize to form an interface modifier.

[0054] The preparation method of rubber asphalt comprises the following steps:

[0055] Step 1, material mixing

[0056] Weigh the petroleum asphalt according to the measurement and put it into the mixing tank A, and heat the petroleum asphalt to 155-170 ° C, in this embodiment, heat to 160 ° C; then weigh the interface modifier according ...

Embodiment 1

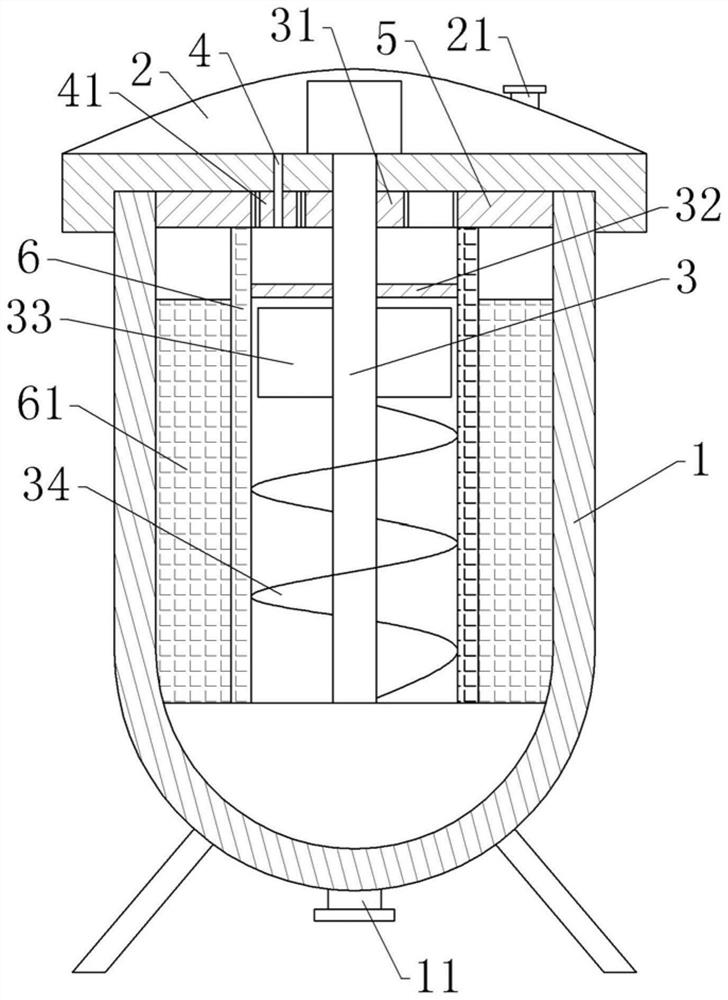

[0069] Embodiment 16 differs from Embodiment 1 only in that, as figure 1 As shown, the present embodiment uses a high-speed shear emulsifier, including a tank body 1, a heating channel is arranged on the outer wall of the tank body 1, and a heat source is connected to the heating channel (for example, water, oil, liquid metal, etc. are passed into the heating channel) . The top of the tank body 1 is provided with a sealing cover body 2 , the sealing cover body 2 is provided with a material inlet 21 , and the bottom of the tank body 1 is provided with a material outlet port 11 . The material inlet 21 is provided with a sealing plug, and the material outlet 11 is provided with a discharge valve.

[0070] The inner side of the sealing cover 2 is fixed with a motor, the driving shaft 4 of the motor is coaxially fixed with the stirring shaft 3, and the driving gear 31 is coaxially fixed on the stirring shaft 3; the sealing cover 2 is also rotatably connected with the driving shaft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com