Hydrofining process for catalytically cracked crude gasoline

A hydrorefining and catalytic cracking technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, and can solve the problems of high energy consumption and large processing capacity of the absorption and stabilization system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

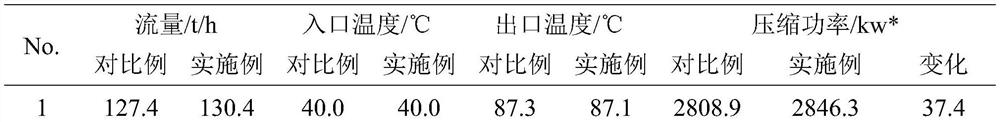

[0033] In this embodiment, a catalytic cracking unit and gasoline hydrogenation unit combined energy-saving technological process, the following improvements are made on the original catalytic cracking unit and technological process:

[0034] The crude gasoline at the top of the main fractionating tower is changed from the original feed into the absorption tower to the gasoline hydrogenation unit directly, and the flow of other pipelines remains unchanged.

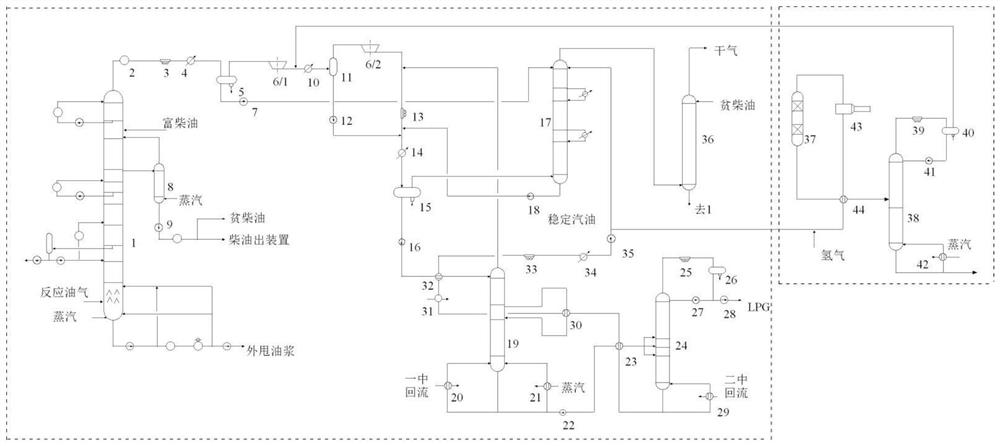

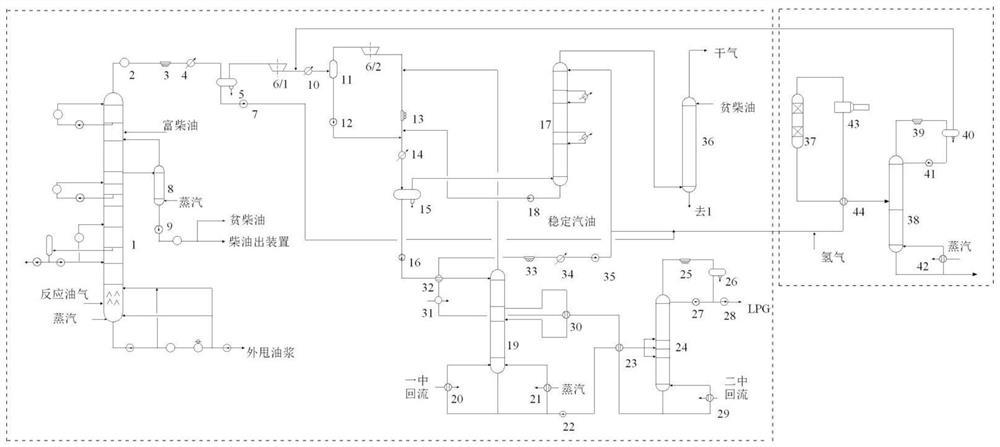

[0035] Its process flow chart is as figure 2 As shown, the specific process flow is as follows:

[0036] The reaction oil and gas from the reaction unit enters the lower part of the herringbone baffle of the main fractionation tower 1, contacts with the circulating oil slurry flowing down from the top of the herringbone baffle from bottom to top, is washed and desuperheated, enters the fractionation part, and undergoes fractionation successively. Refinery oil, diesel oil, crude gasoline and gas are obtained, and the exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com