Nano synthetic lubricating oil and preparation method thereof

A synthetic lubricating oil and nanotechnology, applied in the field of lubricating oil, can solve the problems of many external substances, lubricating oil stability, poor durability, and impact on anti-wear performance, and achieve good overall performance, good performance stability, anti-wear and Good antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

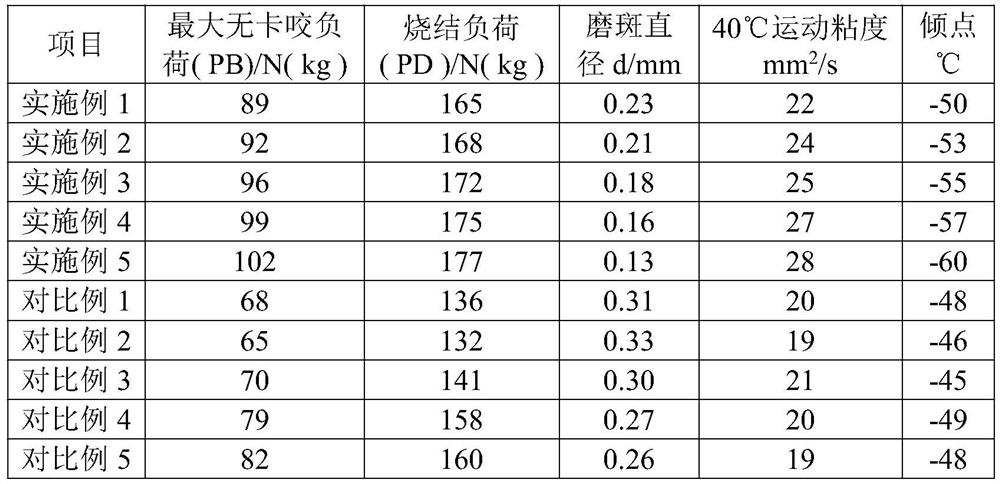

Examples

Embodiment 1

[0027]A nano-synthetic lubricating oil is characterized in that, it is composed of the following components in parts by weight: hydroxyl-terminated hyperbranched nano-hybrid polymer HB-SiO 2 5 parts, 1 part of organic nanomaterials, 3-hydroxy-1-adamantyl methacrylate / (1H,1H,7H-perfluoroheptyl) methacrylate / polyethylene glycol monoallyl ether / 10 parts of dimethyl-vinyl phosphate copolymer, 60 parts of base oil, 0.3 part of antioxidant, 0.5 part of dispersant, and 0.2 part of antiwear agent.

[0028] The anti-wear agent is zinc dialkyl thiosulfate; the dispersant is triethylhexyl phosphoric acid; and the antioxidant is 2,6-tertiary butyl-4-methylphenol.

[0029] The 3-hydroxy-1-adamantyl methacrylate / (1H,1H,7H-perfluoroheptyl) methacrylate / polyethylene glycol monoallyl ether / dimethyl-vinyl phosphoric acid The preparation method of ester copolymer comprises the following steps: 3-hydroxy-1-adamantyl methacrylate, (1H, 1H, 7H-perfluoroheptyl) methacrylate, polyethylene glycol mo...

Embodiment 2

[0033] A nano-synthetic lubricating oil is characterized in that, it is composed of the following components in parts by weight: hydroxyl-terminated hyperbranched nano-hybrid polymer HB-SiO 2 6 parts, 1.5 parts of organic nanomaterials, 3-hydroxy-1-adamantyl methacrylate / (1H,1H,7H-perfluoroheptyl) methacrylate / polyethylene glycol monoallyl ether / 11 parts of dimethyl-vinyl phosphate copolymer, 65 parts of base oil, 0.4 part of antioxidant, 0.6 part of dispersant, and 0.3 part of antiwear agent.

[0034] The anti-wear agent is zinc dialkyl thiosulfate; the dispersant is vinyl bis-stearamide; the antioxidant is bis(3,5-tertiary butyl-4-hydroxyphenyl) thioether.

[0035] The 3-hydroxy-1-adamantyl methacrylate / (1H,1H,7H-perfluoroheptyl) methacrylate / polyethylene glycol monoallyl ether / dimethyl-vinyl phosphoric acid The preparation method of ester copolymer comprises the following steps: 3-hydroxy-1-adamantyl methacrylate, (1H, 1H, 7H-perfluoroheptyl) methacrylate, polyethylene g...

Embodiment 3

[0040] A nano-synthetic lubricating oil is characterized in that, it is composed of the following components in parts by weight: hydroxyl-terminated hyperbranched nano-hybrid polymer HB-SiO 2 6.5 parts, 2 parts of organic nanomaterials, 3-hydroxy-1-adamantyl methacrylate / (1H,1H,7H-perfluoroheptyl) methacrylate / polyethylene glycol monoallyl ether / 13 parts of dimethyl-vinyl phosphate copolymer, 68 parts of base oil, 0.6 part of antioxidant, 0.7 part of dispersant, and 0.35 part of antiwear agent.

[0041] The anti-wear agent is zinc dialkyl thiosulfate; the dispersing agent is monoglyceryl stearate and polyethylene glycol; the antioxidant is tetrakis[beta-(3,5-tertiary butane] yl-4-hydroxyphenyl)propionic acid]pentaerythritol ester.

[0042] The 3-hydroxy-1-adamantyl methacrylate / (1H,1H,7H-perfluoroheptyl) methacrylate / polyethylene glycol monoallyl ether / dimethyl-vinyl phosphoric acid The preparation method of ester copolymer comprises the following steps: 3-hydroxy-1-adamant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com