A kind of 780mpa grade automobile structural steel and production method

A production method and automobile structure technology, applied in the field of 780MPa automobile structural steel and production, can solve the problems of non-corrosion performance and non-compliance with the requirements of high-strength formed automobile parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] See Table 1-5 for the specific composition, temperature regime, finish rolling tension control parameters, properties of the steel plate, and tissue volume percentage of the six embodiments of the present invention.

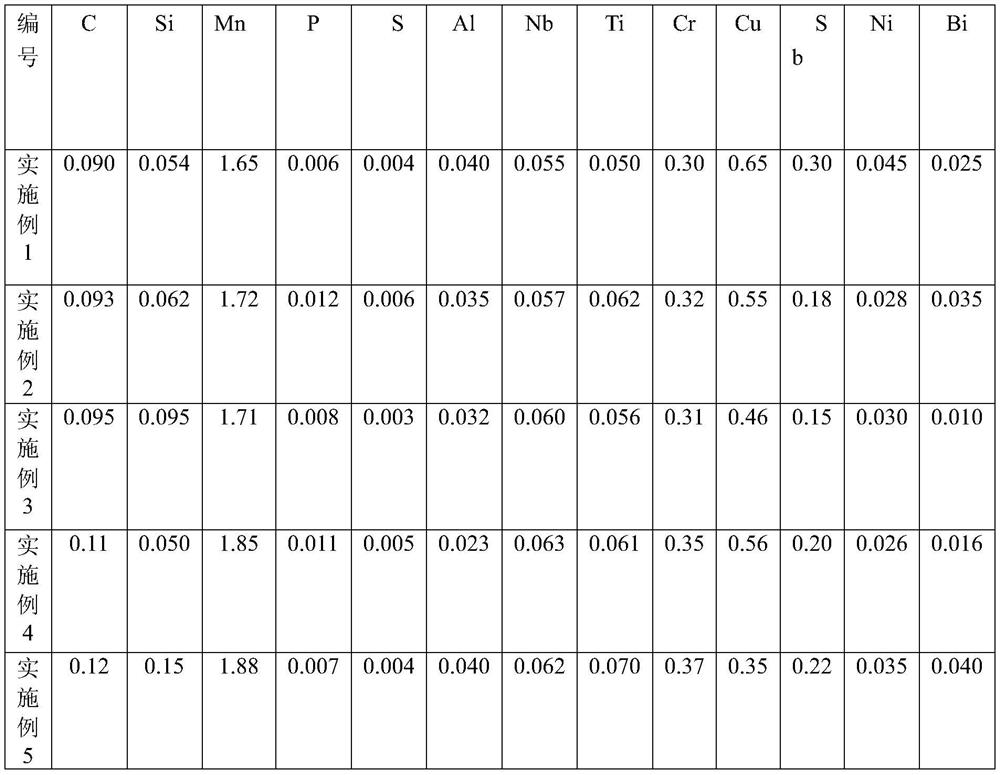

[0049] Table 1 Chemical composition (wt, %) of the embodiment of the present invention

[0050]

[0051]

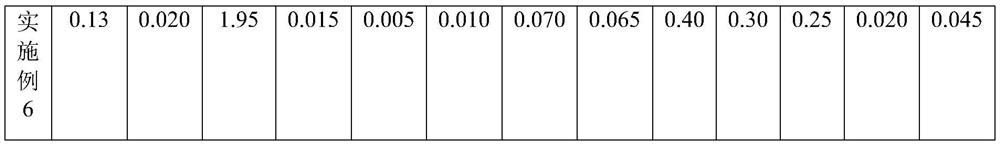

[0052] Table 2 The hot rolling temperature system of the embodiment of the present invention

[0053]

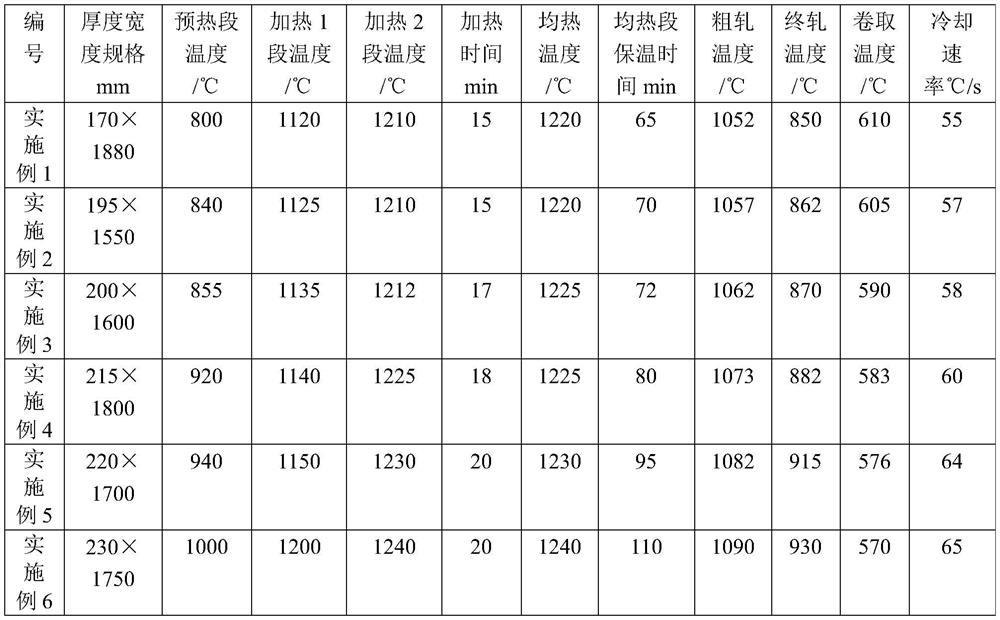

[0054] Table 3 Example finish rolling tension control parameters

[0055]

[0056] The mechanical property parameter of table 4 embodiment of the present invention

[0057]

[0058]

[0059] Tissue volume percentage in the embodiment of the present invention in table 5

[0060] Numbering ferrite Bainite Example 1 0% 100% Example 2 10% 90% Example 3 8% 92% Example 4 14% 86% Example 5 11% 89% Example 6 15% 85%

[0061] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com