Circular-section concrete supporting structure of fabricated wind turbine generator

A technology for wind turbines and supporting structures, which is applied in the installation/support of wind turbine configuration, wind power generation, etc., can solve the problem that the construction quality of the sealing strip cannot be checked visually, affects the construction quality and construction progress, and damages the structural integrity, etc. problems, to achieve the effect of reducing machining accuracy requirements, enhancing survivability, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

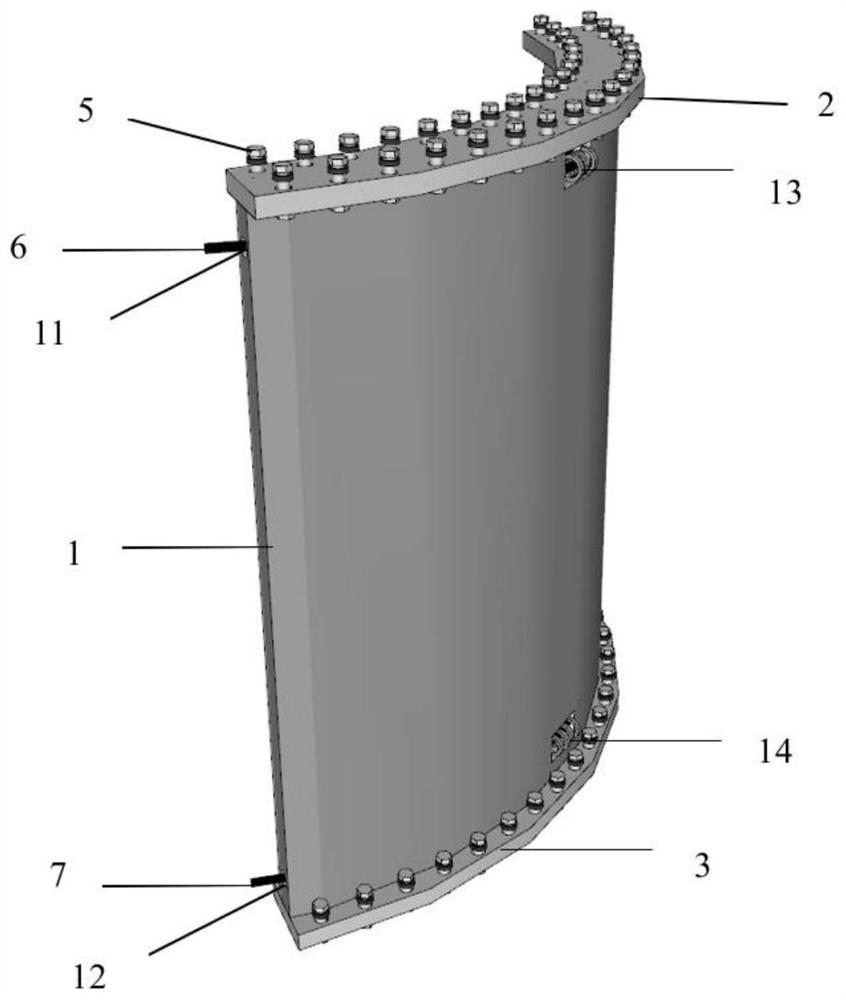

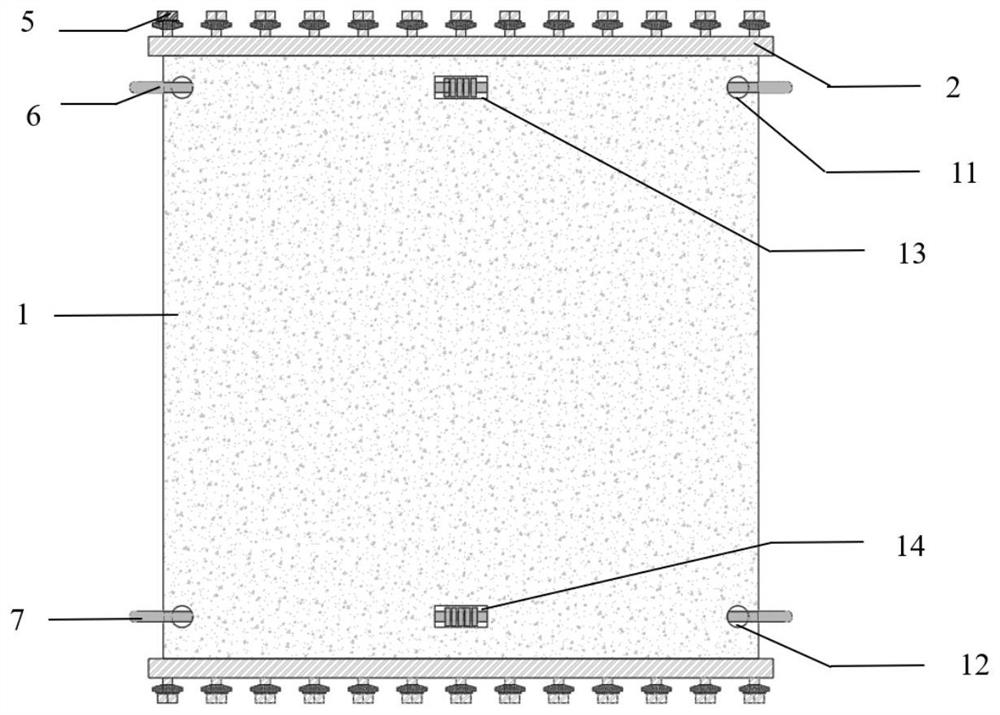

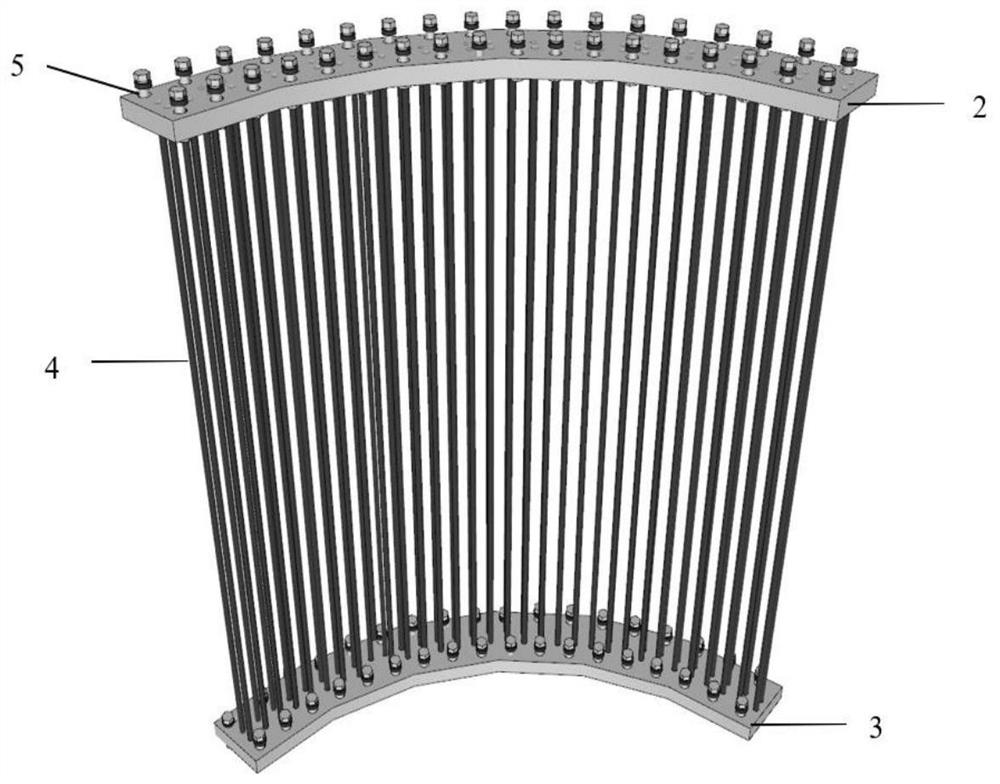

[0023] Such as Figure 1-6 As shown, the circular cross-section concrete support structure of the prefabricated wind turbine of the present invention, when the cross-section of the tower tube is large, the tower tube can be divided into multiple structural units along the ring direction for prefabrication, and when the height of the tower tube is large, it can be The tower is divided into multiple structural units along the longitudinal direction for prefabrication. The structural unit includes a concrete tower section 1, an upper flange 2 and a lower flange 3 with the same structure, a plurality of longitudinal steel bars 4 connecting the upper flange 2 and the lower flange 3, a plurality of high-strength Bolt 5, prestressed steel strand 6 located at the upper part of the tower section, prestressed steel strand 7 located at the lower part of the tower section, the upper flange 2, the lower flange 3 and the longitudinal reinforcement 4 are integrally cast in the factory, The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com