Automatic transmission and installation system for cabin vibration testing

A vibration testing and automatic transmission technology, applied in vibration testing, measuring devices, transportation and packaging, etc., can solve the problems of high labor intensity, low automation level, low work efficiency, etc., to improve traceability and production efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

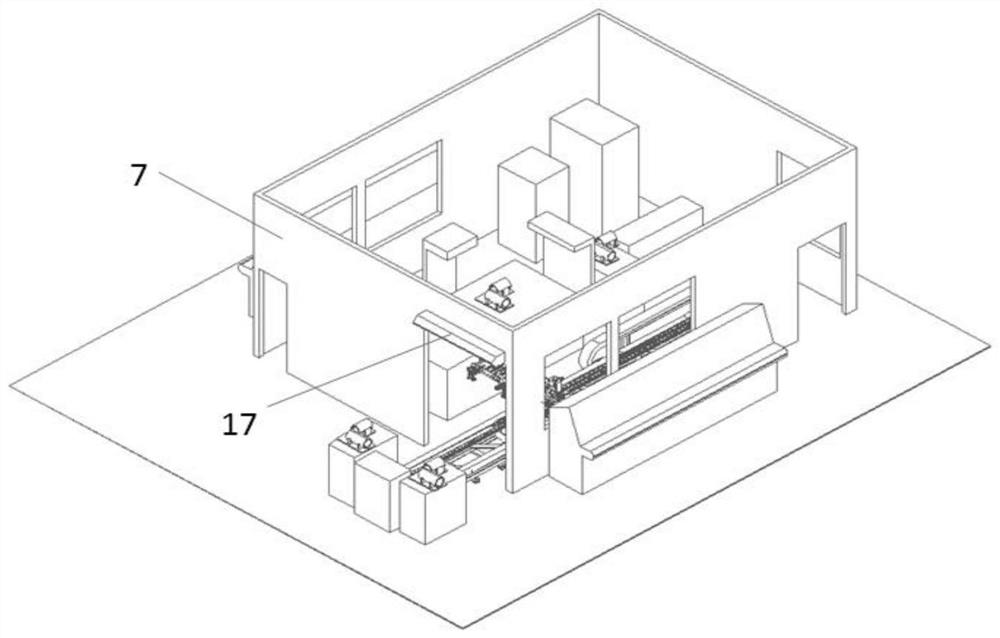

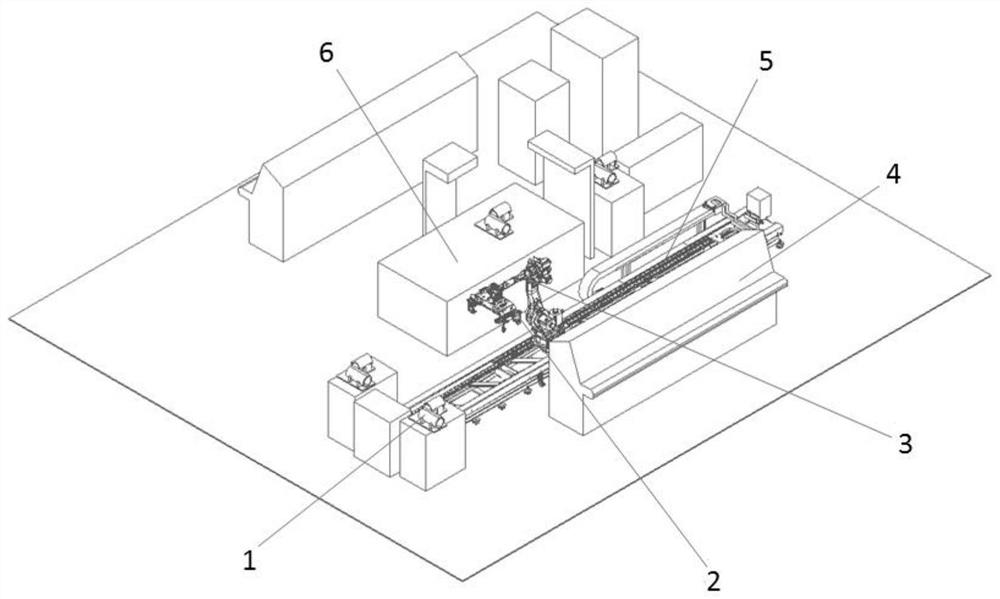

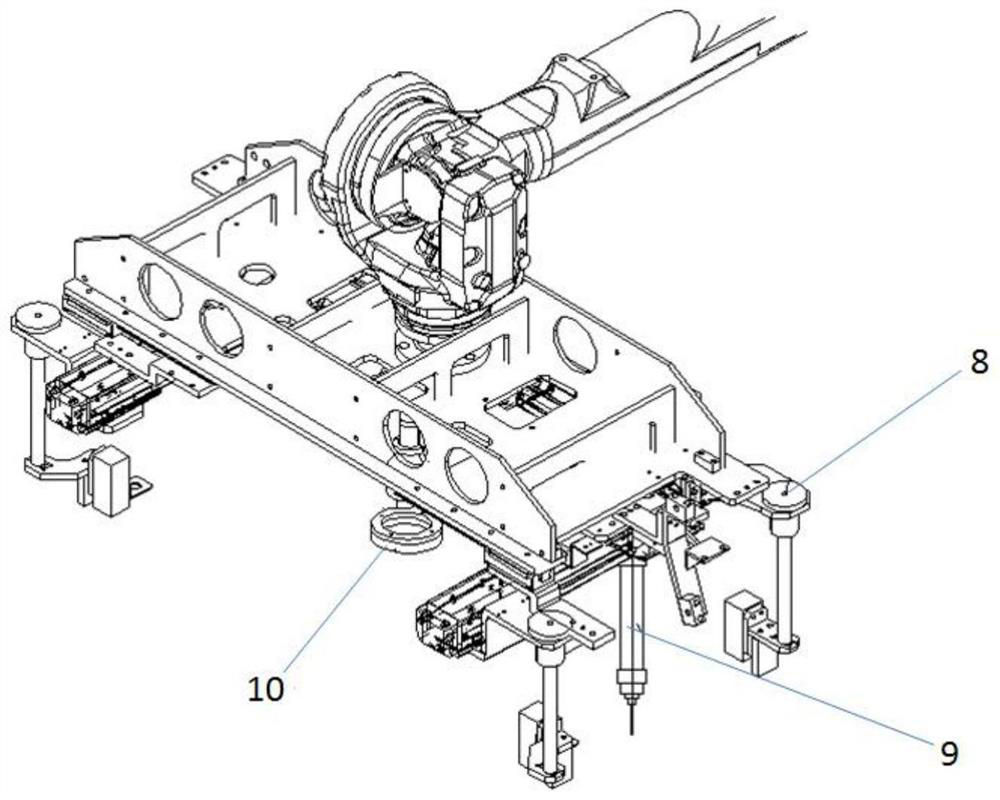

[0029] see Figure 1~5, in an embodiment of the present invention, an automatic transmission and installation system for cabin vibration testing, including an L-shaped fixed cabin fixture 1, a clamping and grabbing tool 2, a robot 3, a robot control system 4, a robot guide rail 5, a vibration table 6 and The vibration test isolation room 7, wherein the vibration table 6 is fixedly installed in the middle position inside the vibration test isolation room 7, and the side wall of the vibration table 6 is provided with a robot guide rail 5, and the robot guide rail 5 is fixedly installed in the vibration test isolation room 7 and one end of the robot guide rail 5 protrudes from the vibration test isolation room 7. At the same time, a robot 3 is installed on the robot guide rail 5. The position of the manipulator of the robot 3 is fixedly equipped with a clamping and grabbing tool 2, and the vibration test isolation room 7 The robot control system 4 is fixedly installed on the side...

Embodiment 2

[0036] see Figure 1-7 , the main structure of this embodiment is the same as that of Embodiment 1, the difference is that: Considering that the experimental cabin section may move on the cabin section fixing fixture 15 during the vibration test process, for this reason, in the cabin section fixing fixture 15 The top is provided with a cover plate 18, the shape of the cover plate 18 is the same as the shape of the cabin fixing fixture 15, and a pair of lower side ears 19 are fixedly installed on the left and right side walls of the top of the cabin fixing fixture 15, and the cover plate 18 A pair of upper ears 20 are fixedly installed on the two side walls of the bottom, wherein the lower ears 19 and the upper ears 20 are fixedly installed together by fixing bolts 21, and the test cabin is fixedly installed between the cabin fixing fixture 15 and the cover plate 18.

[0037] Wherein, the top of the cover plate 18 is provided with a threaded hole 22, the threaded hole 22 is int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com