SESAM and optical fiber coupling structure and packaging method

A technology of coupling structure and packaging method, which is applied in the laser field, can solve the problems of short lifespan of SESAM, and achieve the effect of facilitating mass production, improving stability, and compact volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

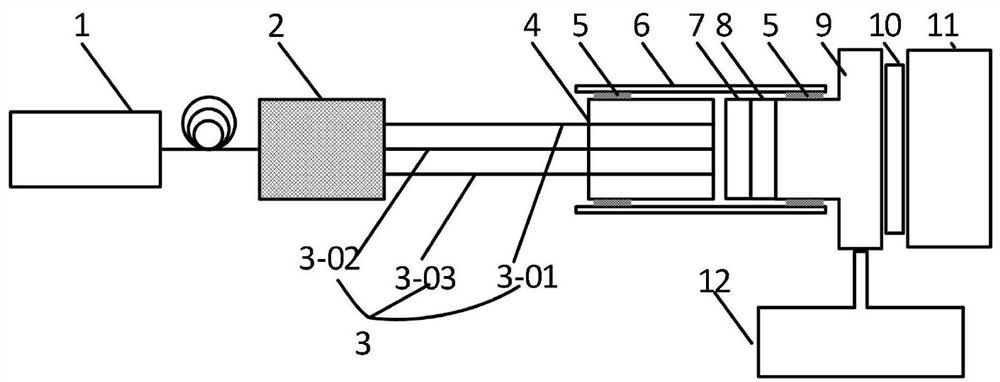

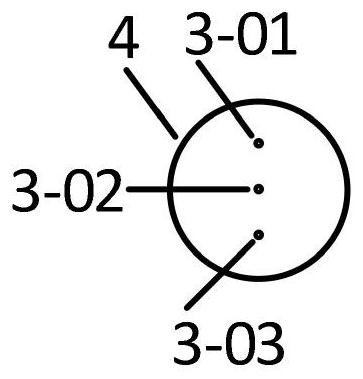

[0052] Embodiment 1 provided by the present invention is an embodiment of the coupling structure of a kind of SESAM and optical fiber provided by the present invention, by figure 1 It can be seen that the embodiment of the coupling structure includes: optical fiber optical path switching device 2, optical fiber 3, plug 4, glass tube 6, SESAM7, adhesive 8, SESAM mount 9, TEC (Thermo Electric Cooler, semiconductor refrigerator) 10, Heat sink 11 and multi-axis mount 12.

[0053] The optical fiber optical path switching device 2 includes an optical fiber optical path at one end and at least one optical fiber optical path at the other end, switches an optical fiber optical path at one end to communicate with any optical fiber optical path at the other end; at least one optical fiber optical path at the other end passes through the corresponding Each optical fiber 3 is plugged into the plug 4 respectively.

[0054] Optical fiber 3 is a polarization-maintaining single-mode fiber or ...

Embodiment 4

[0075] Embodiment 2 provided by the present invention is an embodiment of a packaging method for a SESAM-fiber coupling structure provided by the present invention. The packaging method is based on a SESAM-fiber coupling structure provided in an embodiment of the present invention. Specifically, the Packaging methods include:

[0076] Step 1, inject curing glue into the microholes of the plug 4, set the number of optical fibers 3 according to the requirements, the number is less than or equal to the number of microholes, strip and wipe off the tail coating layer of each optical fiber 3, and then Insert the tails of the optical fiber 3 into the corresponding microholes, and protrude the other end surface of the plug 4 after passing through the plug 4 to cure the curing glue, and then use a grinder to grind the other end surface of the optical fiber 3 passing through the plug 4 Polished to a flat end face, which can be coated or uncoated.

[0077] Step 2, put adhesive on the ra...

Embodiment 3

[0084] Embodiment 3 provided by the present invention is an embodiment of the structure and packaging method of the first specific application embodiment of a SESAM-fiber coupling structure provided by the present invention.

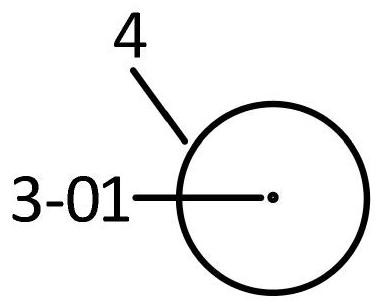

[0085] combine figure 1 and image 3, this embodiment realizes the coupling and packaging method of a single optical fiber and SESAM, including a ceramic plug, a polarization-maintaining single-mode optical fiber, a glass tube, a square SESAM, a heat-conducting adhesive, and a SESAM installation seat, a TEC and a heat sink.

[0086] to combine figure 1 and image 3 , a ceramic plug with an outer diameter of 2mm and a length of 5mm was selected, and there was a microhole with a diameter of 128μm in the center, and heat-cured glue was injected into the microhole.

[0087] to combine figure 1 and image 3 , The optical fiber is a polarization-maintaining single-mode optical fiber with a cladding diameter of 125 μm.

[0088] to combine image 3 After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com