Non-contact transmission mechanism for extreme non-structural environment

A transmission mechanism and non-contact technology, applied in the direction of electromechanical devices, electric components, superconductor elements, etc., can solve the problems of mechanical performance degradation, atomic oxygen erosion, strong thermal expansion and cold contraction of mechanical parts, etc., to achieve effective Use, the effect that the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

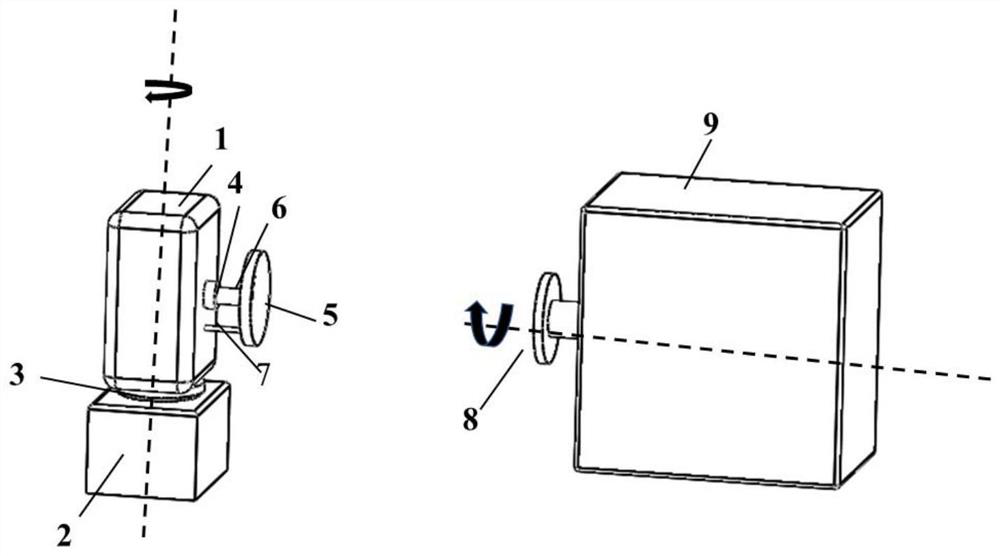

[0030] see figure 1 , the purpose of the implementation required by this embodiment is to achieve the rotational movement of the driven part 8 through the change of the magnetic flux of the superconducting module 6 under the non-contact condition of the components, and the good conductor driven part 8 can realize the rotation through the conversion module 9 The conversion of motion and other forms of motion, so as to achieve the purpose of transmission.

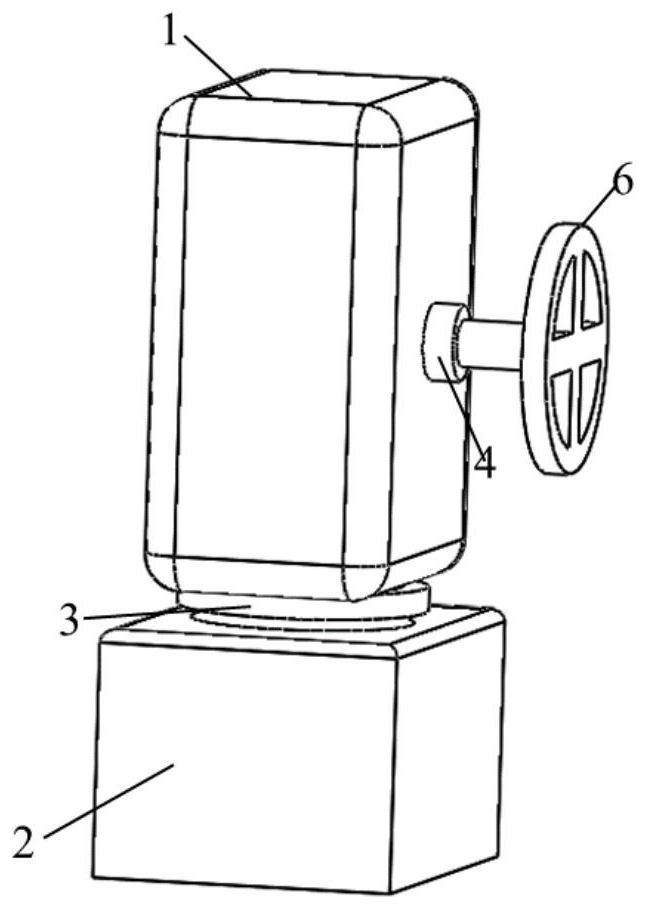

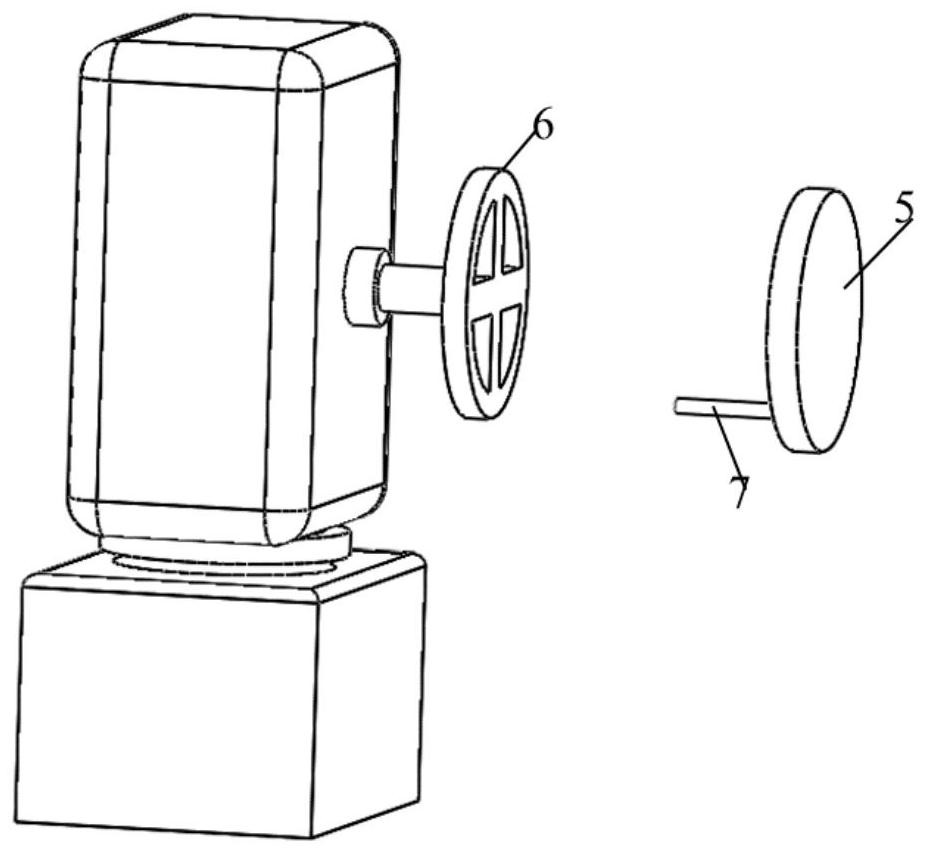

[0031] Such as figure 2 As shown, this embodiment provides a full-circumferential superconducting flux changing module to meet the power requirements of the transmission.

[0032] The superconducting magnetic flux cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com