Synthetic resin skin material and method for producing same

A skin material, synthetic resin technology, applied in synthetic resin layered products, chemical instruments and methods, textiles and paper making, etc. It can reduce the problems such as lowering of the surface energy, and achieve the effect of reducing the surface energy, the freedom of the design, and the freedom of the design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0209] As the resin contained in the composition for forming a vinyl chloride resin skin layer, polyvinyl chloride (Dayang Vinyl Chloride Co., Ltd.: TH-2800) having an average degree of polymerization of 2,800 was used.

[0210] (Composition for forming skin layer)

[0211]

[0212] (Composition for forming foamed resin layer)

[0213] · Polyvinyl chloride resin Taiyang Vinyl Chloride Co., Ltd.: TH-1300:

[0214]

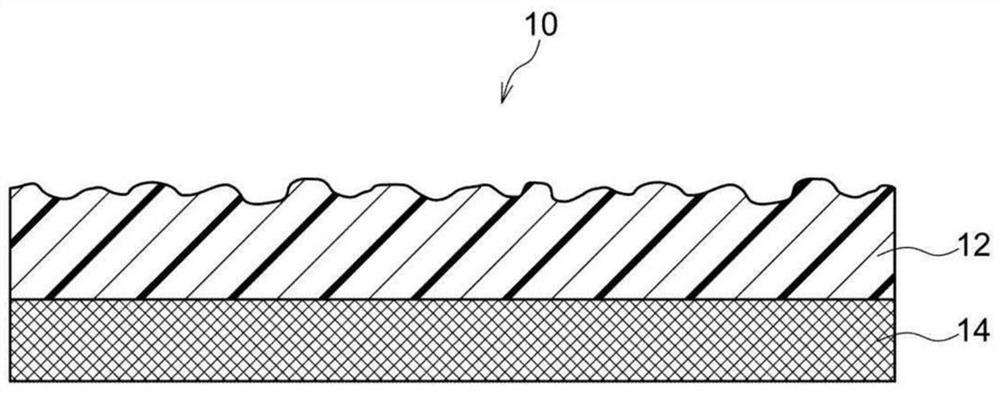

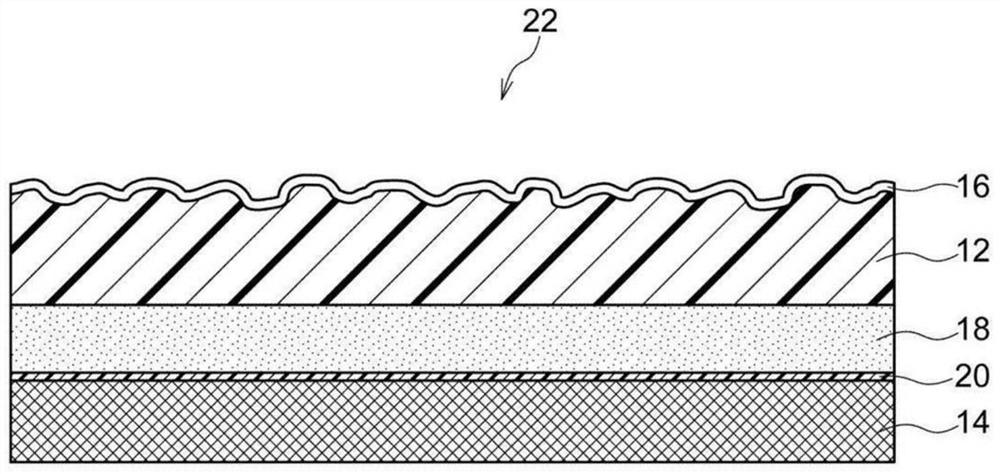

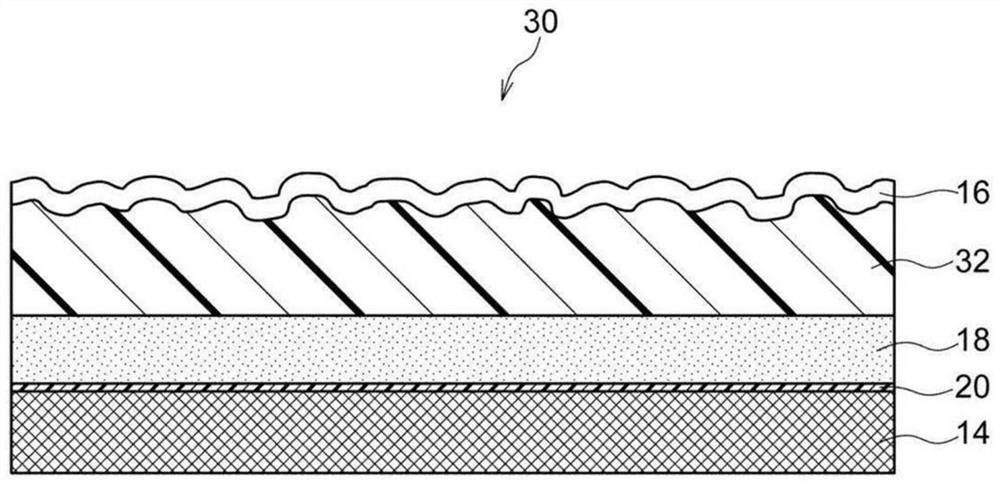

[0215] Using a calendering apparatus, each of the compositions described above was used to form a laminate in which the skin layer and the composition layer for forming a foamed resin layer were laminated. The thickness of the skin layer in the laminate was 250 μm, and the thickness of the foamed resin layer-forming composition layer (before foaming) was 500 μm.

[0216] Apply about 15 g / m to the surface of the composition for forming a foamed resin layer of the obtained laminate 2 Adhesive (polyurethane-based emulsion adhesive) to bond the base fabric.

...

Embodiment 2

[0225] In the same manner as in Example 1, except that the content of the silicone / acrylic copolymer used in Example 1 was replaced by the amount (10 parts by mass) described in Table 1 with respect to 100 parts by mass of vinyl chloride resin with a degree of polymerization of 2800 The skin material of Example 2 was obtained.

Embodiment 3

[0227] In addition to using a vinyl chloride resin with a degree of polymerization of 1700 (Dayang Vinyl Chloride Co., Ltd.: TH-1700) instead of the vinyl chloride resin with a degree of polymerization of 2800 used in Example 1, and replacing the content of the silicone / acrylic copolymer with Table 1 Except for the amount (10 parts by mass) described in , the skin material of Example 3 was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com