Flaky resin composition for encapsulation and semiconductor device

A resin composition and sealing technology, used in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of insufficient effect and low filling, and achieve improved formability and reduced wire flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~4

[0096] The types and compounding amounts of the components listed in Table 1 were mixed using a mixer at normal temperature (25°C), and then heated and kneaded at 80 to 130°C using a hot roll. Under the condition of resin temperature of 60-110° C., rolls were used for rolling and cooling to obtain plates with thicknesses shown in Table 1.

[0097] The obtained board was pulverized using a high-speed pulverizer, and three types of JIS standard sieves (with a sieve diameter of 150 μm, 1 mm, and 2 mm) (JIS Z8801-1:2006 standard) were used to prepare resin compositions for sealing.

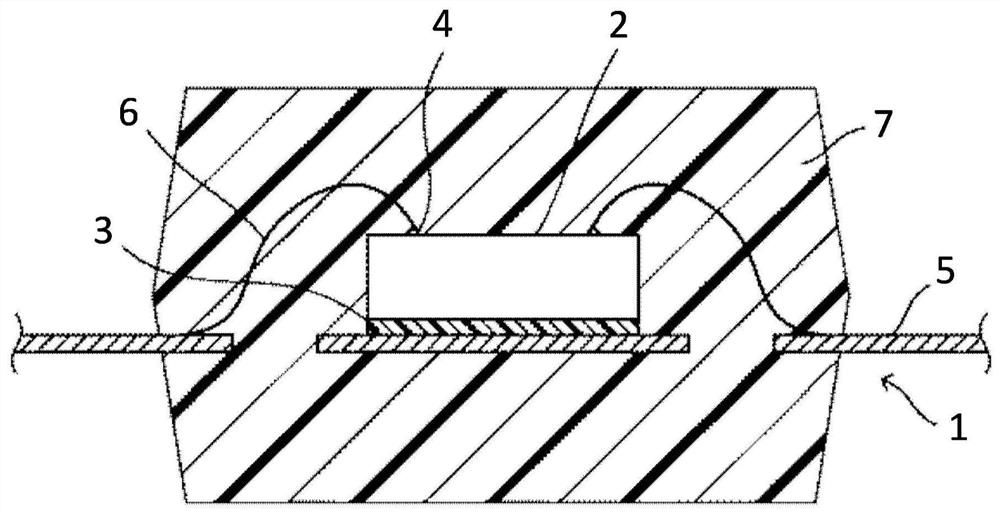

[0098] Moreover, sealing of a semiconductor chip was performed using the obtained resin composition for sealing. That is, using the resin composition for sealing, under the conditions of mold temperature of 175°C, molding pressure of 8.0MPa, and curing time of 2 minutes, a 50mm×50mm×0.54mm FBGA (Fine pitch Ball Grid Array, fine pitch ball grid array ) After compression molding, post-curing was perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com