Shoe tree magnetic attraction suspension type shoe sole glue spraying and drying equipment

A drying equipment and hanging technology, which is applied to the field of shoe sole spraying and drying equipment, can solve the problems of affecting the yield, uneven gluing of the upper edge, easy displacement of the upper, etc., to achieve the effect of ensuring the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

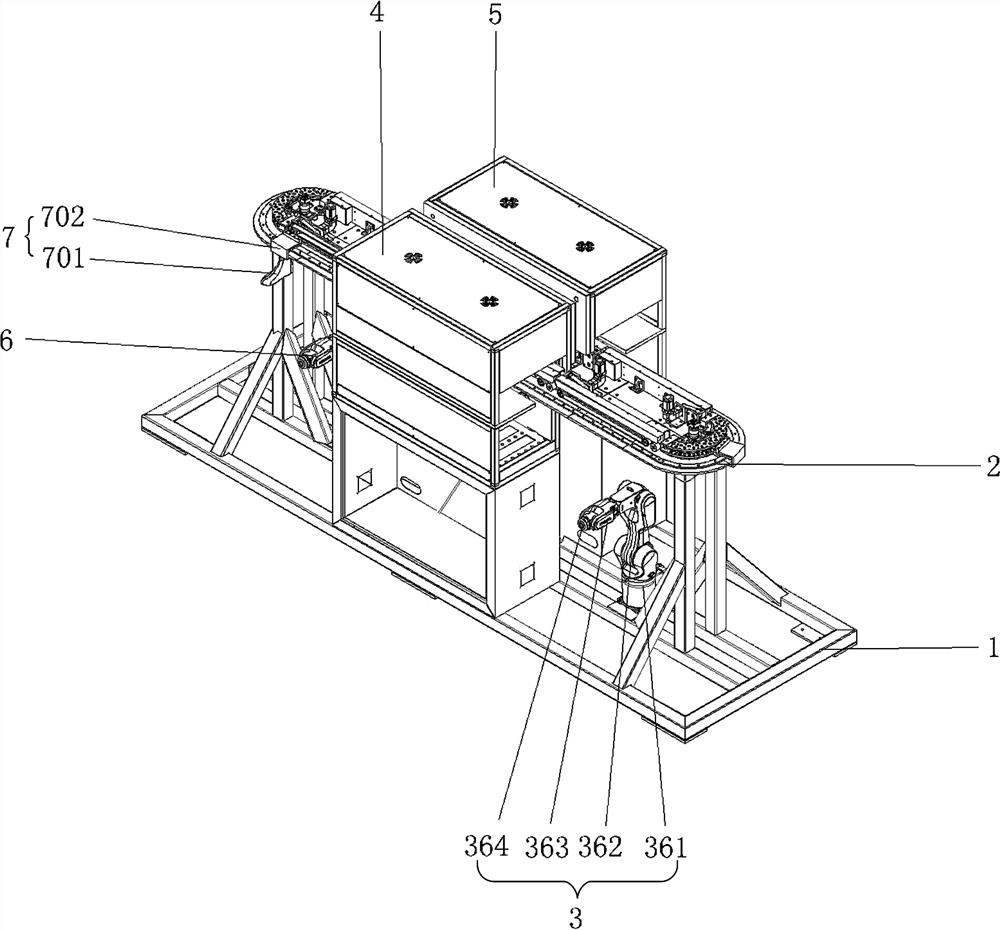

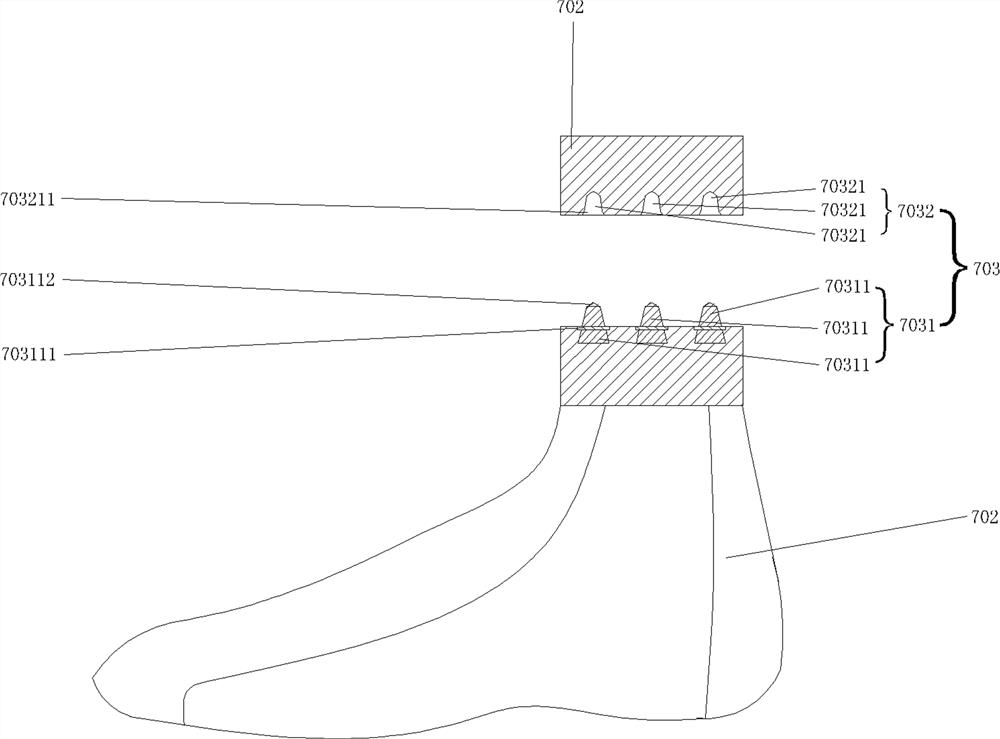

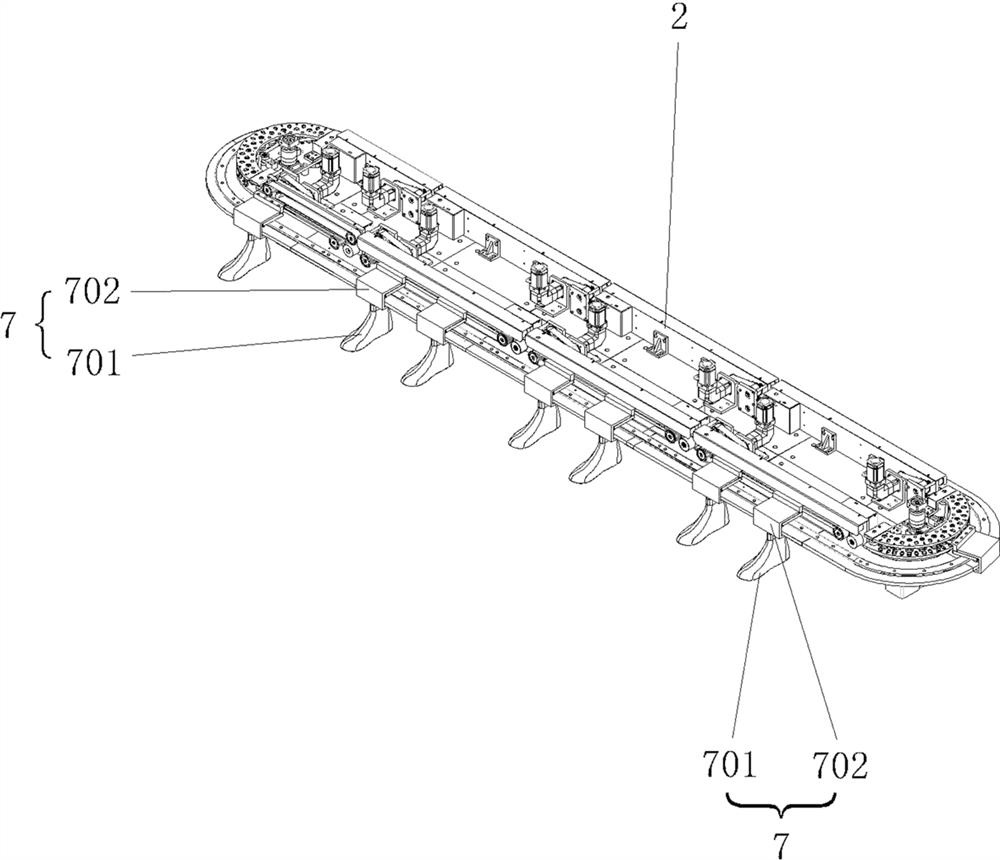

[0030] Such as Figure 1-2 Shown is a shoe last magnetic suction hanging sole glue spray drying equipment, including a frame 1, a conveying device 2, a feeding manipulator 3, a glue spraying device 4, a drying device 5, a feeding manipulator 6 and a plurality of The shoe last positioning device 7, the conveying device 2 is installed on the frame 1, the shoe last positioning device 7 includes a shoe last 701, a shoe last seat 702 and a shoe last hanging positioning device 703, the shoe last seat 702 is arranged on the conveying device 2, the shoe last The last suspension positioning device 703 includes a first magnetic positioning mechanism 7031 and a second magnetic positioning mechanism 7032, the first magnetic positioning mechanism 7031 includes three positioning pins 70311, and each positioning pin 70311 is installed on the top surface of the last opening of the shoe last 701 , and each positioning pin 70311 is perpendicular to the top surface of the last system mouth, one ...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that: the three positioning pins are all strong magnetic positioning pins; the three pin holes are all pin sleeves made of magnetic metal.

Embodiment 3

[0041]The difference between this embodiment and Embodiment 1 is that the first magnetic positioning mechanism includes three pin holes arranged on the top surface of the shoe last system opening, each pin hole is vertically arranged with the opening facing upwards, and one of the pin holes is formed by The pin sleeve made of strong magnetic metal is embedded in the top surface of the last opening; the second magnetic positioning mechanism includes three positioning pins, and each positioning pin is installed on the lower surface of the shoe last seat. The number of holes is the same and the positions correspond to each other. The positioning pin corresponding to the position of the pin sleeve is made of magnetic metal or a magnet that can attract each other with the pin sleeve; the shoe last seat is matched with the pin hole of the shoe last through the positioning pin , and the latch sleeve and the corresponding positioning pin made of magnetic metal are attracted to each oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com