A kind of rubber composition containing organic acid metal salt phenolic resin compound and its preparation method and application

A technology of rubber composition and phenolic resin, used in transportation and packaging, special tires, tire parts, etc., can solve the problems of low dynamic adhesion, weak force, and reduced protection of the adhesive layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

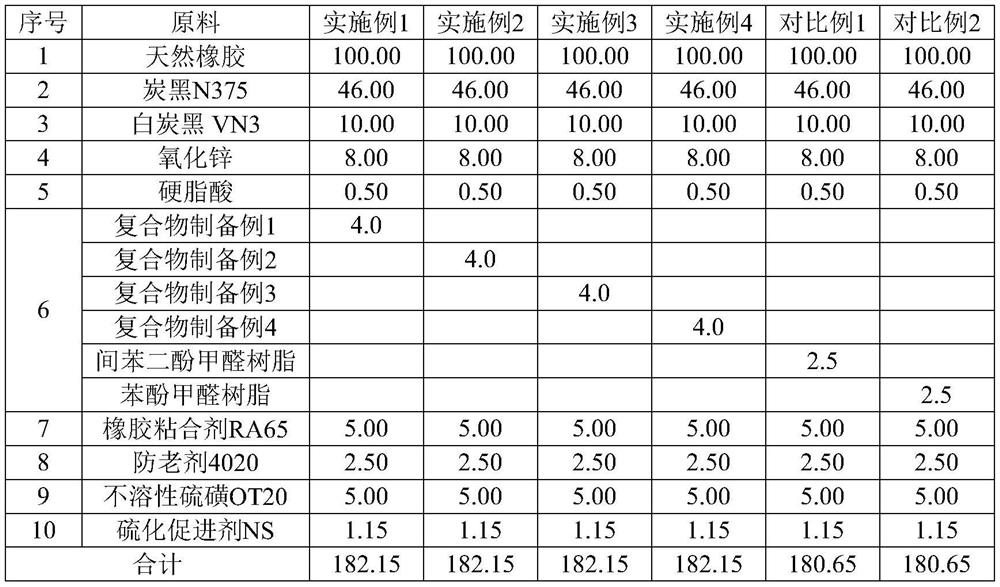

Method used

Image

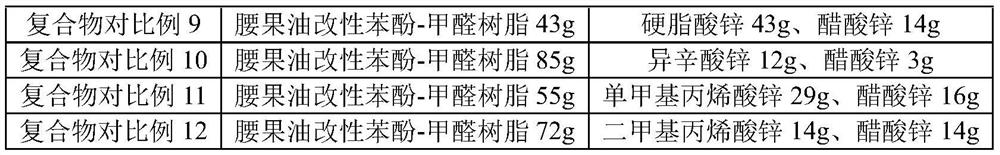

Examples

Embodiment 2

[0081] Compared with Comparative Example 1 in Example 2, the organic acid metal salt phenolic resin compound used in this application can improve the modulus of the sizing material by 12%, and reduce the compression heat generation temperature of the sizing material by 12%. When it reached 4 degrees, the compression set of the rubber compound was improved by 23%, and the adhesive force between rubber and steel wire was also improved, especially the dynamic steel wire adhesive force after aging, which increased by 33%.

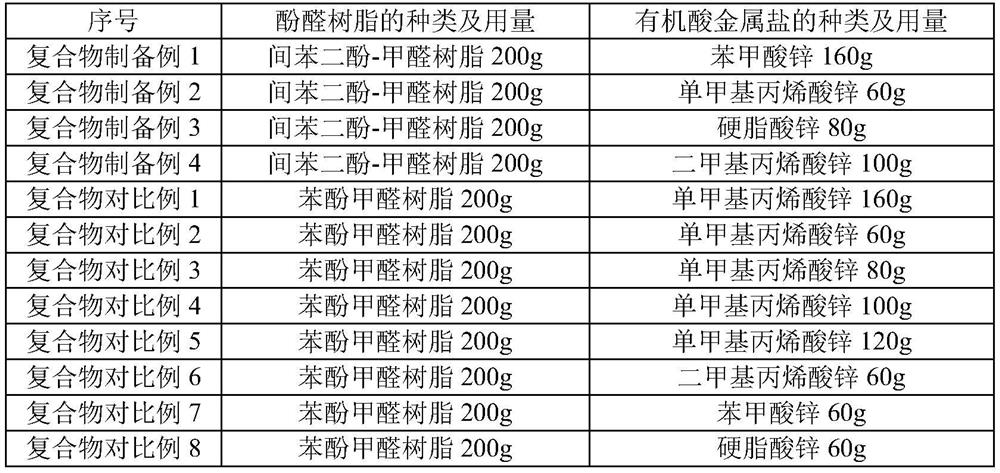

[0082] The list of ingredients of table 4 rubber composition (unit: parts by weight)

[0083]

[0084] The performance test data of table 5 rubber composition

[0085]

[0086] As can be seen from Table 4-5, compared with comparative examples 3-10, the resorcinol formaldehyde resin containing organic acid metal salt in embodiment 2 shows a good performance in reducing the heat generation of the rubber compound and improving the adhesion between rubber and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com