Nitrile rubber composition and crosslinked rubber product

A technology of nitrile rubber and composition, which is applied in the field of rubber cross-linked products, and can solve the problems of large dynamic heat generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

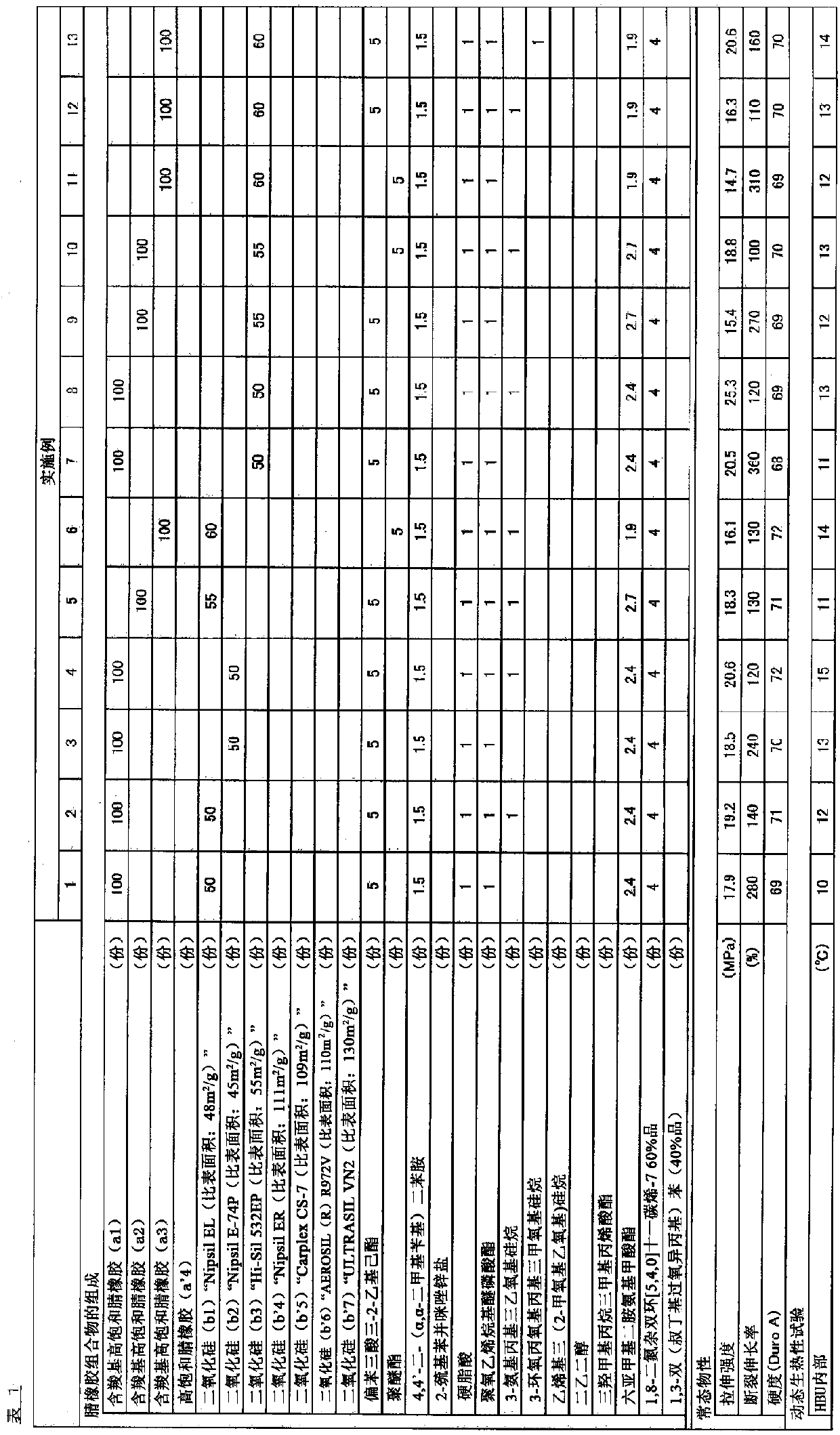

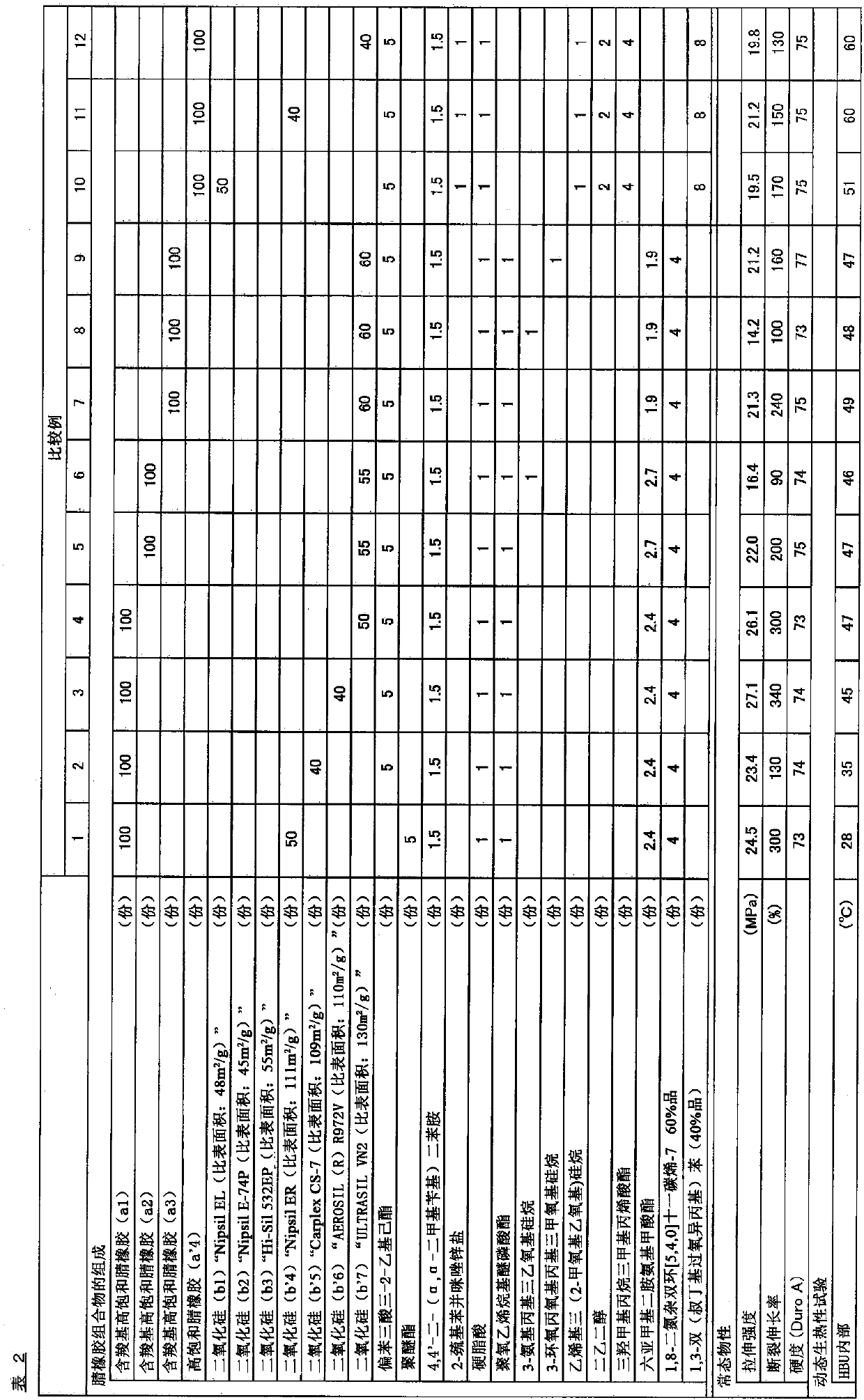

[0112] Hereinafter, an Example and a comparative example are given, and this invention is demonstrated concretely. Hereinafter, unless otherwise stated, "parts" are based on weight. In addition, tests and evaluations are as follows.

[0113] Carboxyl content

[0114] Add 100mL of 2-butanone to the carboxyl group-containing highly saturated nitrile rubber of 2mm square of 0.2g, after stirring for 16 hours, add 20mL of ethanol and 10mL of water, carry out the 0.02N aqueous ethanol solution using potassium hydroxide while stirring, Titration using thymolphthalein as an indicator at room temperature can thereby obtain the number of moles of carboxyl groups with respect to 100 g of rubber (unit ephr).

[0115] Composition of carboxyl-containing highly saturated nitrile rubber

[0116] The content ratio of each monomer unit constituting the carboxyl group-containing highly saturated nitrile rubber was measured by the following method.

[0117] That is, the content ratio of t...

manufacture example 1

[0129] Production example 1 (production of carboxyl group-containing highly saturated nitrile rubber (a1))

[0130] In the reactor, 220 parts of ion-exchanged water, 5 parts of 10% sodium dodecylbenzenesulfonate aqueous solution, 37 parts of acrylonitrile, 4 parts of mono-n-butyl maleate and 0.75 parts of tertiary dodecyl mercaptan (molecular weight regulator), and after substituting the internal gas with nitrogen three times, 57 parts of 1,3-butadiene were added. Then, keep the reactor at 10°C, add 0.06 parts of cumene hydroperoxide (polymerization initiator), an appropriate amount of reducing agent and chelating agent, continue the polymerization reaction while stirring, and reach 40% and 60% at the polymerization conversion rate At the moment, add 1 part of mono-n-butyl maleate, respectively, and when the polymerization conversion rate reaches 85%, add 0.1 part of hydroquinone aqueous solution (polymerization terminator) with a concentration of 10% by weight to terminate ...

manufacture example 2

[0133] Production example 2 (production of carboxyl group-containing highly saturated nitrile rubber (a2))

[0134] In the reactor, 180 parts of ion-exchanged water, 25 parts of 10% sodium dodecylbenzenesulfonate aqueous solution, 23 parts of acrylonitrile, 6.5 parts of mono-n-butyl maleate, 30.5 parts methoxyethyl acrylate and 0.65 parts of tert-dodecyl mercaptan (molecular weight regulator), and after replacing the internal gas with nitrogen three times, 40 parts of 1,3-butadiene were added. Then, keep the reactor at 10°C, add 0.06 parts of cumene hydroperoxide (polymerization initiator), an appropriate amount of reducing agent and chelating agent, continue the polymerization reaction while stirring, and when the polymerization conversion rate reaches 83%, The polymerization reaction was terminated by adding 0.1 part of a hydroquinone aqueous solution (polymerization terminator) having a concentration of 10% by weight. Next, residual monomers were removed at a water tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com