Novel traceless multifunctional training shoe rubber sole and preparation method thereof

A multi-functional, training shoe technology, applied in the field of shoe processing, can solve the problems of high friction coefficient between rubber sole and ground, large dynamic heat generation of rubber sole, and affecting the appearance of contacting ground, etc., to achieve small dynamic heat generation, clean surface and mixed uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

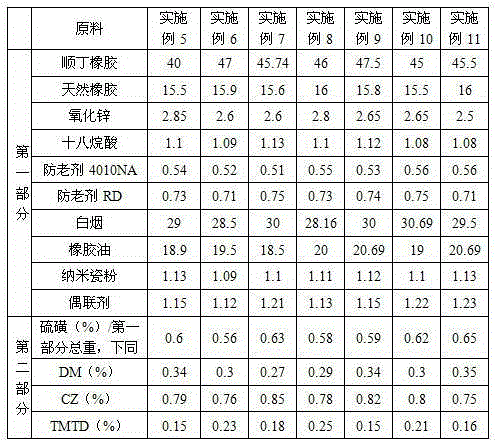

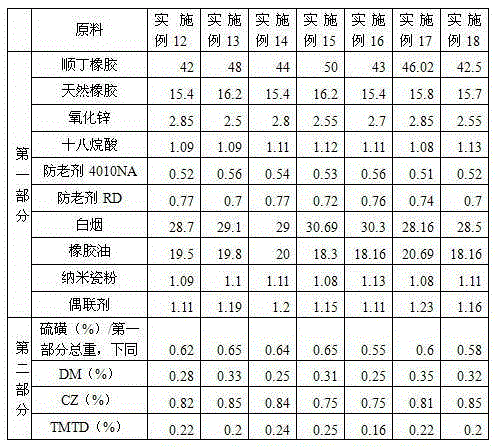

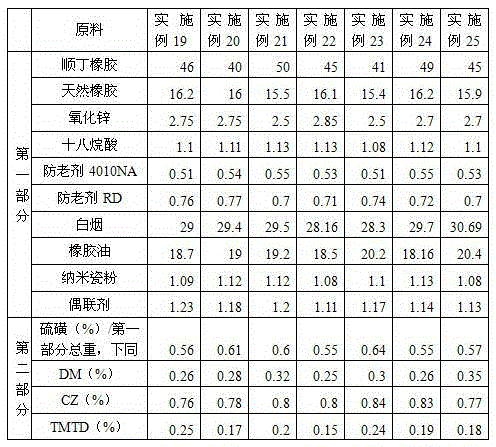

[0019] A new type of non-trace multifunctional training shoe rubber sole, the formula raw material is divided into two parts, the first part is composed of the following raw materials in parts by weight: 40-50 parts of butadiene rubber, 15.4-16.2 parts of natural rubber, 2.50-2.85 parts of zinc oxide 1.08-1.13 parts of octadecanoic acid, 1.21-1.33 parts of anti-aging agent, 28.16-30.69 parts of white smoke, 18.16-20.69 parts of rubber oil, 1.08-1.13 parts of nano ceramic powder, 1.11-1.23 parts of coupling agent; The part is composed of the following raw materials in percentages of the total weight of the first part of raw materials: sulfur 0.55-0.65, vulcanization accelerator 1.15-1.45. The anti-aging agent consists of 0.51-0.56 parts by weight of N-isopropyl-N'-phenyl-p-phenylenediamine (anti-aging agent 4010NA) and 0.70-0.77 parts by weight of 2,2,4-trimethyl-1,2- Composed of dihydroquinoline (antiaging agent RD); the coupling agent is a silane coupling agent; the vulcaniza...

Embodiment 2

[0028] A new type of non-trace multifunctional training shoe rubber sole, its formula raw materials are divided into two parts, the first part is composed of the following raw materials: 45.74kg of butadiene rubber, 15.4kg of natural rubber, 2.85kg of zinc oxide, 1.13kg of octadecanoic acid, Anti-aging agent 4010NA0.53kg, anti-aging agent RD0.75kg, white smoke 30kg, rubber oil 19kg, nano-porcelain powder 1.13kg, silane coupling agent silicon-691.11kg; the total weight of the first part of raw materials is 117.64kg; the second part is made of sulfur 707g , accelerator DM353g, accelerator CZ943.12g, accelerator TMTD235.78g.

[0029] The preparation method of the rubber sole of the novel non-trace multifunctional training shoes as described above adopts the reverse mixing method, and specifically includes the following steps:

[0030] (1) Put white smoke, nano ceramic powder, zinc oxide, octadecanoic acid, coupling agent, anti-aging agent, and 1 / 2 of rubber oil into the internal ...

Embodiment 3

[0035] A new type of non-trace multifunctional training shoe rubber sole, its formula raw materials are divided into two parts, the first part is composed of the following raw materials: 46.02kg of butadiene rubber, 16kg of natural rubber, 2.50kg of zinc oxide, 1.1kg of stearic acid, anti-aging Agent 4010NA0.55kg, antioxidant RD0.7kg, white smoke 29kg, rubber oil 20kg, nano ceramic powder 1.1kg, silane coupling agent silicon-691.2kg; the total weight of the first part of raw materials is 118.17kg; the second part consists of sulfur 709g, Accelerator DM354g, accelerator CZ886.28g, accelerator TMTD236.34g.

[0036] The preparation method of the rubber sole of the novel non-trace multifunctional training shoes as described above adopts the reverse mixing method, and specifically includes the following steps:

[0037] (1) Put white smoke, nano porcelain powder, zinc oxide, octadecanoic acid, coupling agent, anti-aging agent, and 40% rubber oil into the internal mixer and mix evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com