Multi-layer body

A technology for lamination and formation of layers, applied in the direction of coating, layered products, metal layered products, etc., can solve the problems of insufficient microcircuit formability and reduced productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

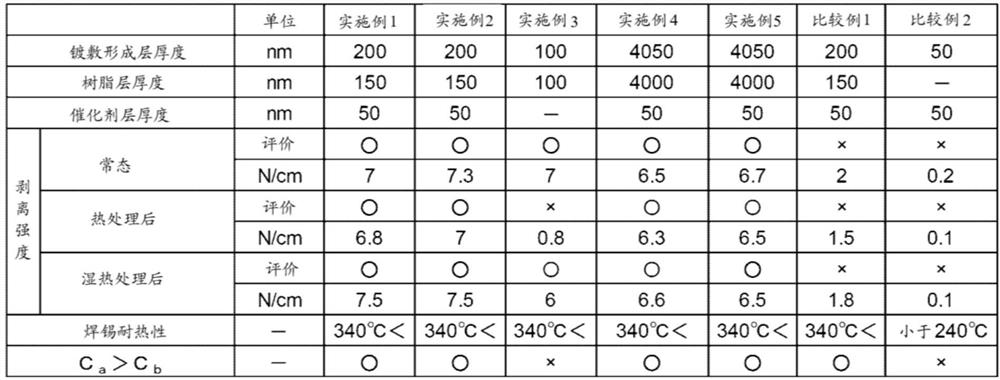

[0108] Hereinafter, although an Example and a comparative example demonstrate this invention more concretely, this invention is not limited to these Examples.

[0109] Although the synthesis examples of the thermoplastic resin used as the raw material of the resin layer of this invention are demonstrated concretely below, this invention is not limited to these synthesis examples.

[0110]Acid dianhydrides, diamines, and solvents used to synthesize thermoplastic resins are shown below.

[0111] p-PDA: p-phenylenediamine (manufactured by Kanto Chemical Co., Ltd.)

[0112] BAPP: 2,2-bis(4-aminophenoxyphenyl)isopropane (manufactured by Wakayama Seika Kogyo Co., Ltd.)

[0113] TPE-R: 1,3-bis(4-aminophenoxy)benzene (manufactured by Wakayama Seika Kogyo Co., Ltd.)

[0114] 4,4'-DPE: 4,4'-diaminodiphenyl ether (manufactured by Wakayama Seika Kogyo Co., Ltd.)

[0115] BPDA: 3,4,3',4'-biphenyltetracarboxylic dianhydride (manufactured by Ube Industries, Ltd.)

[0116] DMAc: N,N-Dimet...

Synthetic example 1

[0119] After adding 85 g of DMAc, 1.034 g (0.003 mol) of BAPP, and 6.628 g (0.023 mol) of TPE-R to the reaction vessel, it was stirred at room temperature to dissolve BAPP and TPE-R in DMAc. To the resulting solution was slowly added 7.338 g (0.025 mol) of BPDA. Then, it stirred at room temperature for 3 hours, and obtained the resin composition (polyamic acid solution). It diluted with DMAc so that the solid content concentration of the obtained polyamic-acid solution might become 2 mass %, and the polyamic-acid solution A was obtained.

Synthetic example 2

[0121] 85 g of DMAc, 5.645 g (0.014 mol) of BAPP, and 2.680 g (0.009 mol) of TPE-R were added to the reaction container, and stirred at room temperature to dissolve BAPP and TPE-R in DMAc. To the resulting solution was slowly added 6.675 g (0.023 mol) of BPDA. Then, it stirred at room temperature for 3 hours, and obtained the resin composition (polyamic acid solution). It diluted with DMAc so that the solid content concentration of the obtained polyamic-acid solution might become 2 mass %, and the polyamic-acid solution B was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com