Low-temperature composite solder alloy soldering lug, and preparation method and use method thereof

An alloy soldering sheet and composite welding technology, which is applied to the composition of low-temperature composite solder alloy soldering sheet, composite soldering sheet, and the field of forming solder joints, can solve the problems of poor mechanical properties, high cost, low melting point, etc., and achieve good plasticity and strength. The effect of lifting and shear strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: This low-temperature composite solder alloy solder sheet includes a 24.51% high-temperature layer and a 75.49% low-temperature layer, and a layer of low-temperature layers are respectively arranged on both sides of the high-temperature layer, wherein the high-temperature layer welding material is Sn-0.7Cu alloy, and the solidus temperature is 229.3°C, the low-temperature layer welding material is Sn-52In eutectic alloy, and the solidus temperature is 120.5°C;

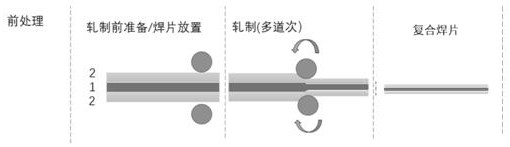

[0040] The preparation of the above-mentioned low temperature composite solder alloy solder sheet is as follows ( figure 1 ): Sn-0.7Cu alloy and Sn-52In eutectic alloy were pre-rolled into solder pieces with a thickness of 0.25mm and 0.5mm respectively, and the target size was cut out, and alcohol ultrasonic cleaning, dilute hydrochloric acid cleaning, alcohol ultrasonic cleaning, After drying; place a low-temperature layer on both sides of the high-temperature layer to form a sandwich structure, a...

Embodiment 2

[0043]Embodiment 2: This low-temperature composite solder alloy solder sheet includes a 47.72% high-temperature layer and a 52.28% low-temperature layer, and one layer of low-temperature layers is respectively arranged on both sides of the high-temperature layer, wherein the high-temperature layer welding material is Sn-0.7Cu alloy, and the solidus temperature is 229.3°C, the low-temperature layer welding material is Sn-52In eutectic alloy, and the solidus temperature is 120.5°C;

[0044] The preparation of the above-mentioned low-temperature composite solder alloy solder sheet is as follows: the Sn-0.7Cu alloy and the Sn-52In eutectic alloy are pre-rolled into solder sheets with a thickness of 1.00mm and 0.25mm respectively, and the target size is cut out, and cleaned by alcohol ultrasonic , dilute hydrochloric acid cleaning, alcohol ultrasonic cleaning, and drying; place a low-temperature layer on both sides of the high-temperature layer to form a sandwich structure, and put ...

Embodiment 3

[0047] Embodiment 3: The low-temperature composite solder alloy solder sheet includes a 60.1% high-temperature layer and a 39.9% low-temperature layer, and a layer of low-temperature layers is respectively arranged on both sides of the high-temperature layer, wherein the high-temperature layer welding material is Sn-0.7Cu alloy, and the solidus temperature is 229.3°C, the low-temperature layer welding material is Sn-52In eutectic alloy, and the solidus temperature is 120.5°C;

[0048] The preparation of the above-mentioned low-temperature composite solder alloy solder sheet is as follows: respectively pre-roll the Sn-0.7Cu alloy and the Sn-52In eutectic alloy into solder sheets with a thickness of 1.00mm and 0.10mm, cut out the target size, and clean them with alcohol ultrasonic , dilute hydrochloric acid cleaning, alcohol ultrasonic cleaning, and drying; place a low-temperature layer on both sides of the high-temperature layer to form a sandwich structure, and put it into a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidus temperature | aaaaa | aaaaa |

| Solidus temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com