Rubber composite material using cardanol glycidyl ether modified silica and preparation method thereof

A technology of glycidyl ether and composite materials, which is applied in the field of inorganic nano powder modification, can solve problems such as high energy consumption, environmental risks, and high pollution, and achieve the effects of low price, improved static mechanical properties, and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

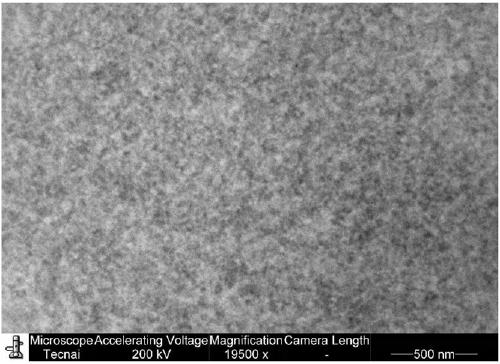

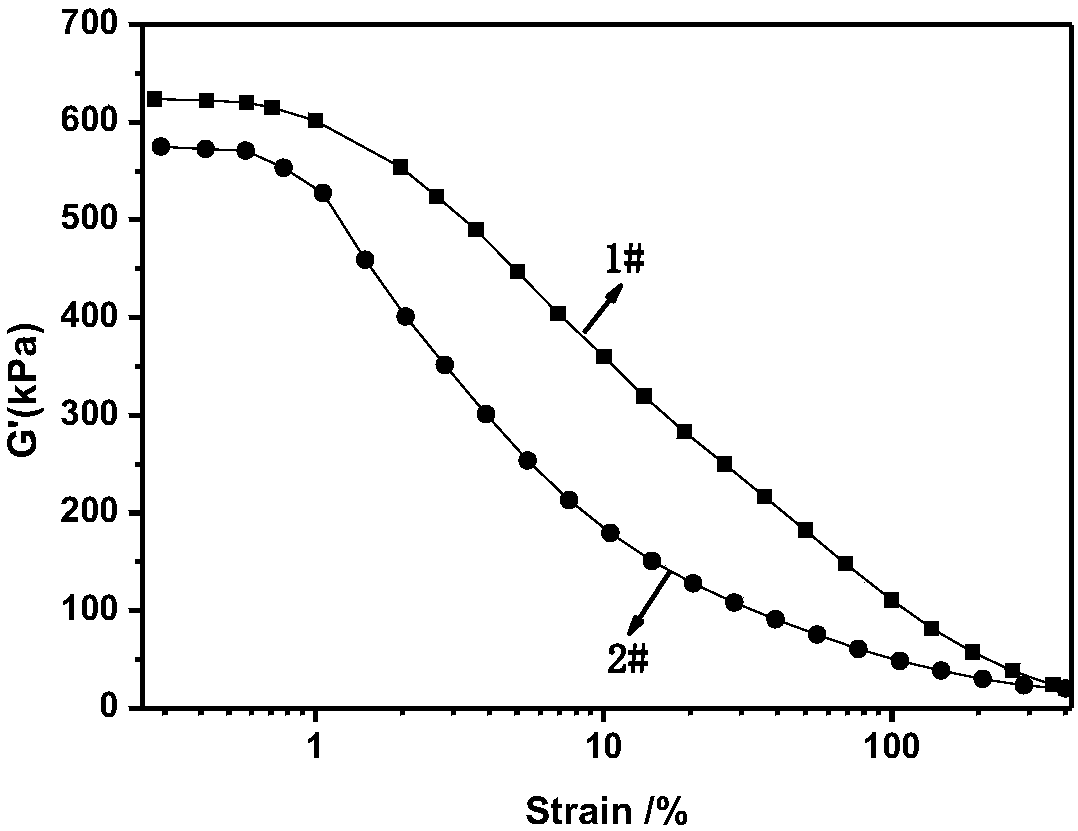

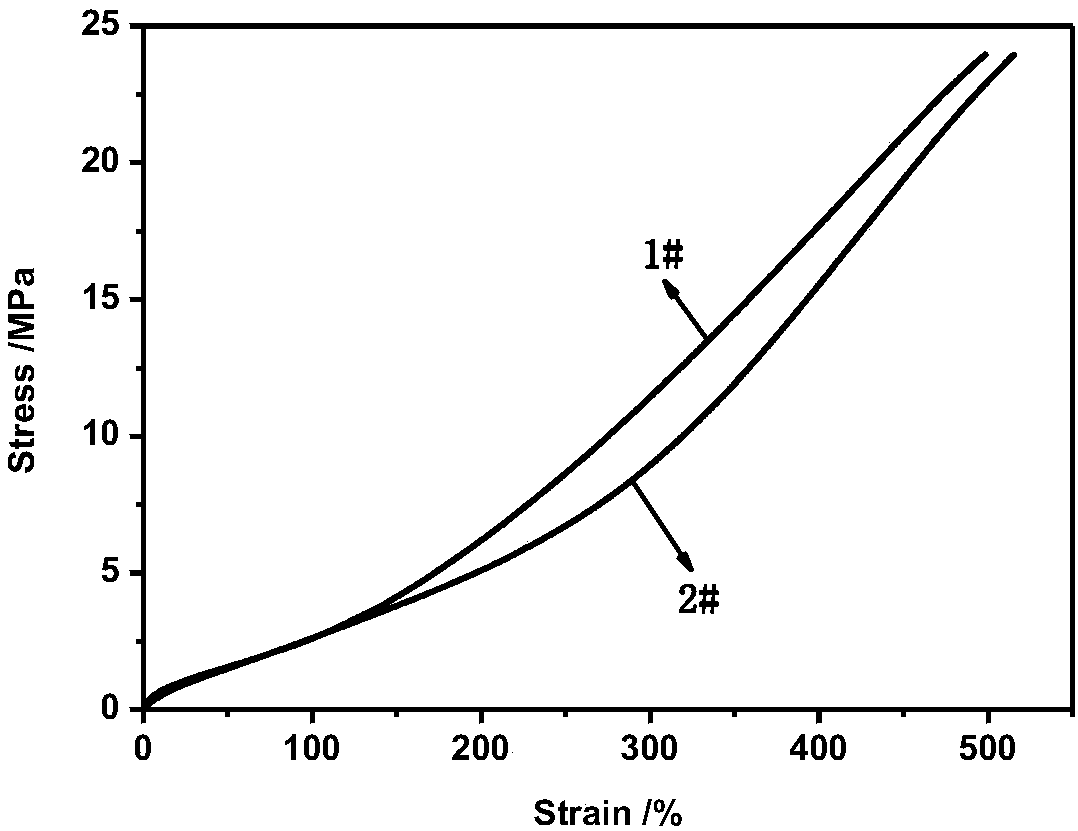

Image

Examples

Embodiment 1

[0054] Take 100 parts by weight of polystyrene butadiene rubber (SBR1502) and put it into a closed mixer, set the rotor speed to 80r / min, and the temperature in the cavity to 45°C, masticate the rubber for 3 minutes, and finally keep the rubber in continuous flow the molten state. Get 60 parts by weight of white carbon black (K160) powder, add in the closed mixer in 2 times within 3 minutes; Get 6 parts by weight of cardanol glycidyl ether and 1.5 parts by weight of silane coupling agent Si75 simultaneously, White carbon black is added to the closed mixer at the same time. After adding the silica, continue to knead for 3 minutes, then adjust the temperature in the kneader chamber to above 90°C, and knead for another 7 minutes, so as to promote the silica to pass through the hydroxyl group on its surface and one end of the cardanol glycidyl ether molecule. The reaction of the epoxy group of the filler realizes the in-situ modification of the filler. Finally, the rubber compou...

Embodiment 2

[0056] Take 100 parts by weight of natural rubber and put it into a closed mixer, set the rotor speed to 70r / min, and the temperature in the cavity to 40°C, masticate the rubber for 3 minutes, and finally keep the rubber in a molten state of continuous flow. Take 70 parts by weight of white carbon black (VN3) powder, add it into the closed mixer in 3 times within 5 minutes; in the mixer. After adding the silica, continue to knead for 6 minutes, then adjust the temperature in the kneader chamber to above 90°C, and knead for another 8 minutes to make the silica pass through the hydroxyl group on its surface and one end of the cardanol glycidyl ether molecule. The reaction of the epoxy group of the filler realizes the in-situ modification of the filler. Finally, the rubber compound is discharged to complete the mixing of the rubber and the inorganic filler to obtain the natural rubber / modified white carbon black masterbatch. After the obtained masterbatch was cooled to room tem...

Embodiment 3

[0069] Get 100 parts by weight of natural rubber and put it between the double rolls of an open kneader, repeat the mastication for 5 times, so that the rubber can keep the molten state of continuous flow on the rolls. Adjust the roller distance between the two rollers to about 2mm, take 100 parts by weight of white carbon black (VN3) powder, and gradually mix the white carbon black into the rubber when there is accumulation of rubber between the two rollers; at the same time take 10 parts by weight of cardanol glycidol Ether and 2 parts by weight of silane coupling agent KH590 are mixed into the rubber while adding white carbon black. After adding the white carbon black, continue mixing for 4 minutes and remove the rubber. Adjust the roller temperature of the open kneader to above 90°C, and knead the rubber for another 6 minutes to promote the reaction of the hydroxyl group on the surface of the silica with the epoxy group at one end of the cardanol glycidyl ether molecule to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com