Toughened glass ceramic with low surface compressive stress and raw glass

A surface compressive stress, strengthening glass technology, applied in the field of glass, can solve the problems of signal transmission time delay, low dielectric loss of glass, signal strength attenuation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation method of the strengthened glass-ceramic is to prepare the strengthened glass-ceramic after performing microcrystallization heat treatment and ion exchange treatment on the original glass.

[0070] The key to the preparation method lies in the physical and chemical characteristics of the original glass. Specifically, the original glass, in molar percentage, contains the following composition: 60-80% SiO 2 ;3-11% Al 2 o 3 ;0.5-8% P 2 o 5 and / or B 2 o 3 ;7-18% Li 2 O; 0-2% Na 2 O; 0-2% K 2 O; 1-6% ZrO 2 ;0-2% TiO 2 ;0-1% SnO 2 . Preferably, the original glass contains 68-75% SiO 2 ; 5-7% Al 2 o 3 ;2-7% P 2 o 5 and / or B 2 o 3 ;7.5-15% Li 2O; 0-1% Na 2 O; 0-1% K 2 O; 2-5% ZrO 2 ;0-1% TiO 2 ;0.1-0.5% SnO 2 . Optionally, the original glass also includes 0-8 mol% of other oxides, the other oxides include MgO, ZnO and Tm 2 o 3 one or more of. Optionally, the original glass may not contain Na 2 O.

[0071] The Young's modulus of the...

Embodiment 1-5

[0078] Example 1-5: Preparing strengthened glass ceramics from raw glass

[0079] In Examples 1-5, the original glass I, original glass II, original glass III, original glass IV, and original glass V of batches (1000 pieces) were passed through the above-mentioned microcrystallization heat treatment and ionization respectively. The exchange treatment produced batches (1000 pieces) of strengthened glass-ceramics I, strengthened glass-ceramics II, strengthened glass-ceramics III, strengthened glass-ceramics IV, and strengthened glass-ceramics V.

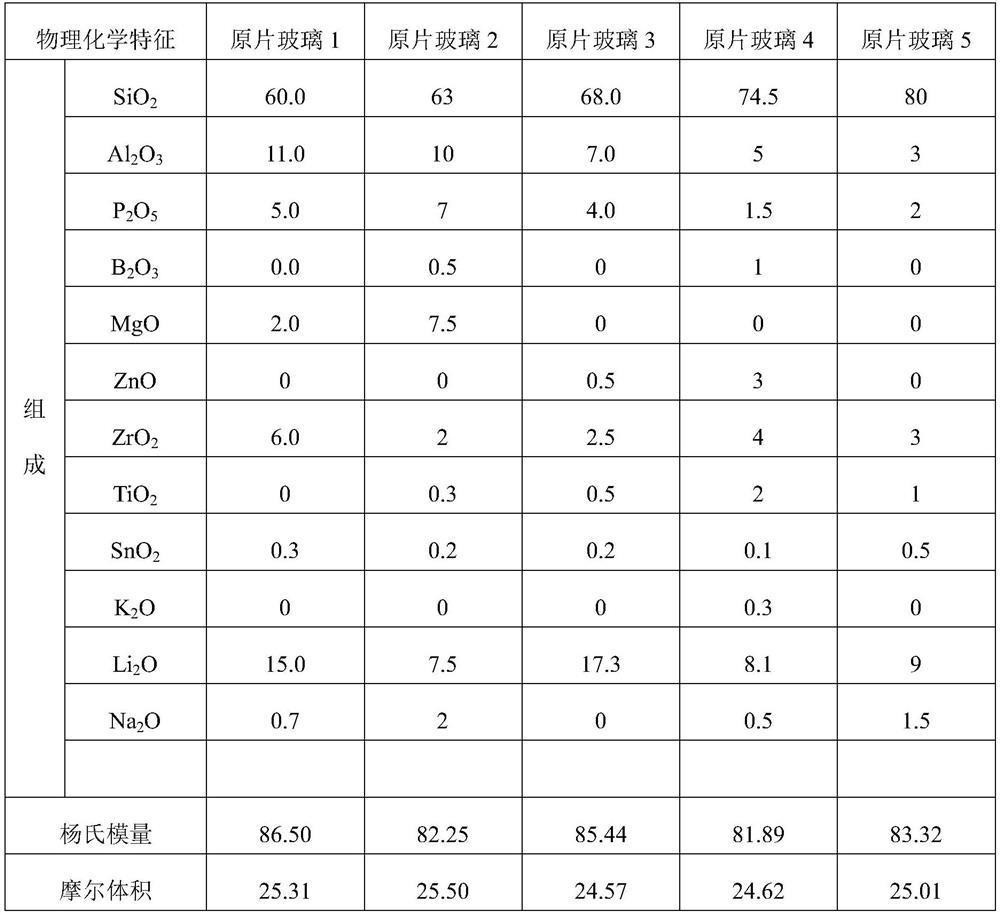

[0080] The physical and chemical characteristics of the original glass I to V are shown in the table below.

[0081]

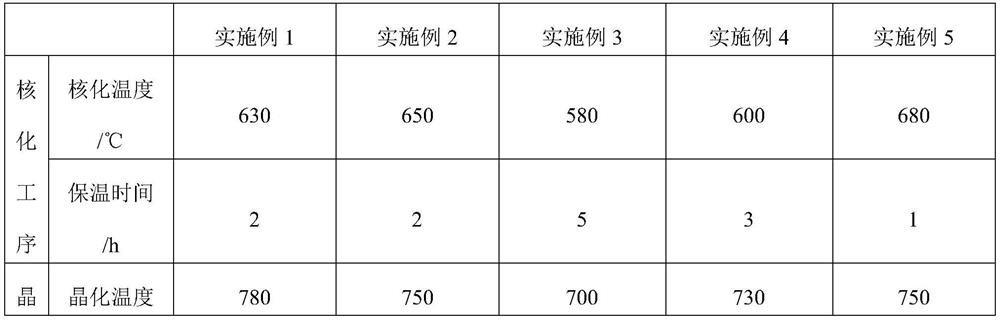

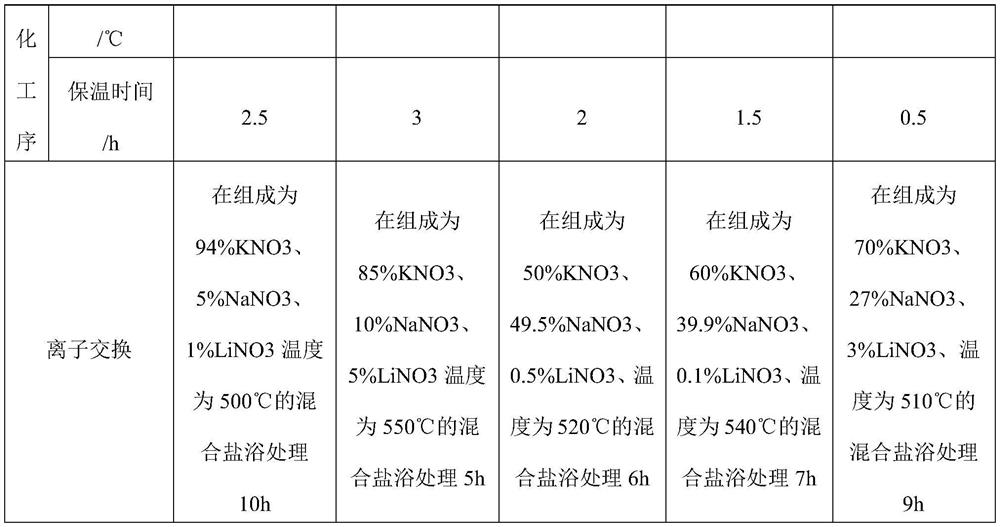

[0082] The parameters involved in microcrystallization heat treatment and ion exchange treatment of original glass I, original glass II, original glass III, original glass IV and original glass V are shown in the table below.

[0083]

[0084]

[0085] The composition of the crystals in the prepared strengthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| molar volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com