OEE and Andon management system and working method thereof

A management system, andon technology, applied in the direction of manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of inconvenient use for operators, high cost and maintenance cost, and increase the burden on enterprises, so as to achieve convenient query and realization of reports Equipment efficiency, quick import effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

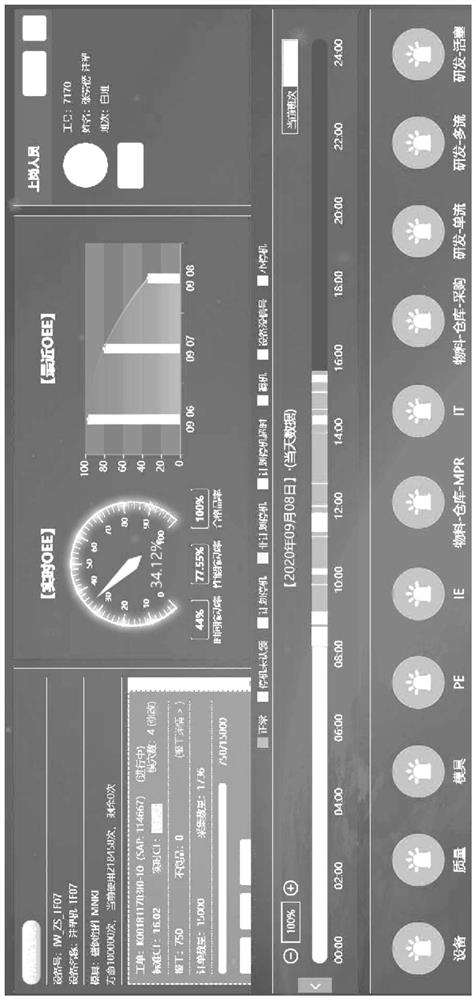

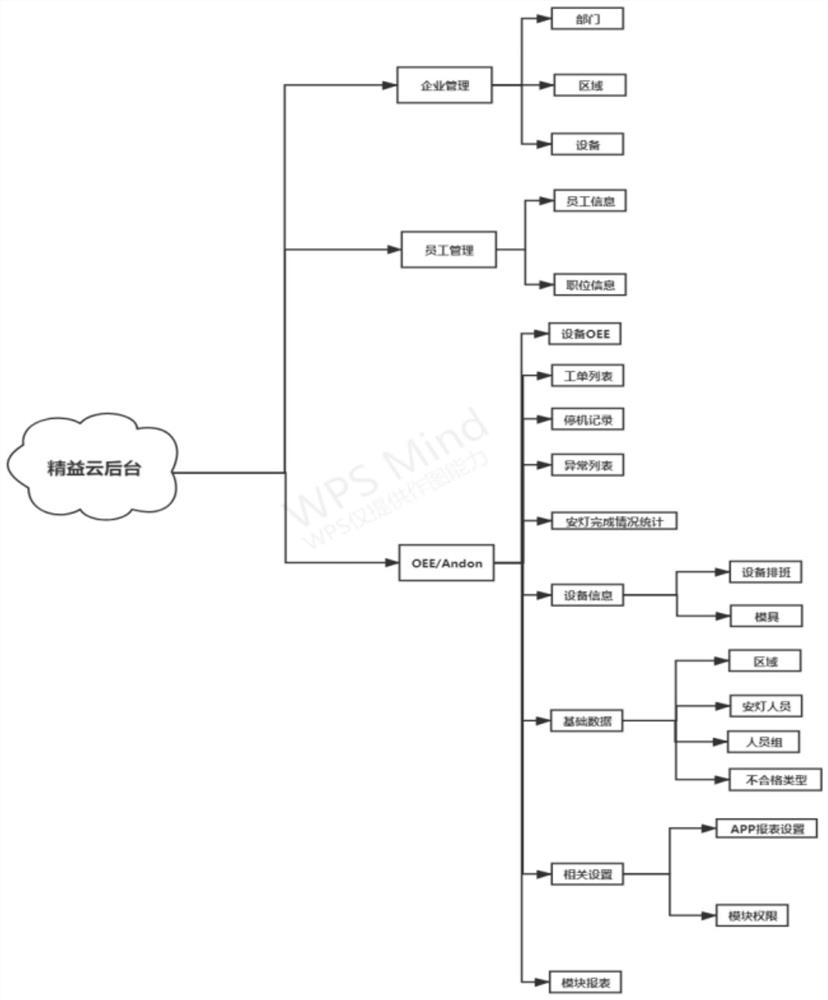

[0049] like Figure 1-3 OEE shown with Andon management system including

[0050] System background maintenance module: configure basic information according to user needs;

[0051] Work order online module: used to obtain the ERP or MES work order information of the upper system in real time, connect through the standard interface API, and provide standard report import, and import the work order information of ERP or MES tasks into OEE and Andon management systems;

[0052] Personnel online module: collect and report various information in real time according to the personnel mobile APP, and draw various information of personnel work;

[0053] Equipment online module: The system is set to prepare a unique identity code for each equipment, collect equipment status information, equipment capacity, start-up time, and downtime through the equipment interface, and calculate the time utilization rate of each equipment every day through the planning and scheduling. Collect the stan...

Embodiment 2

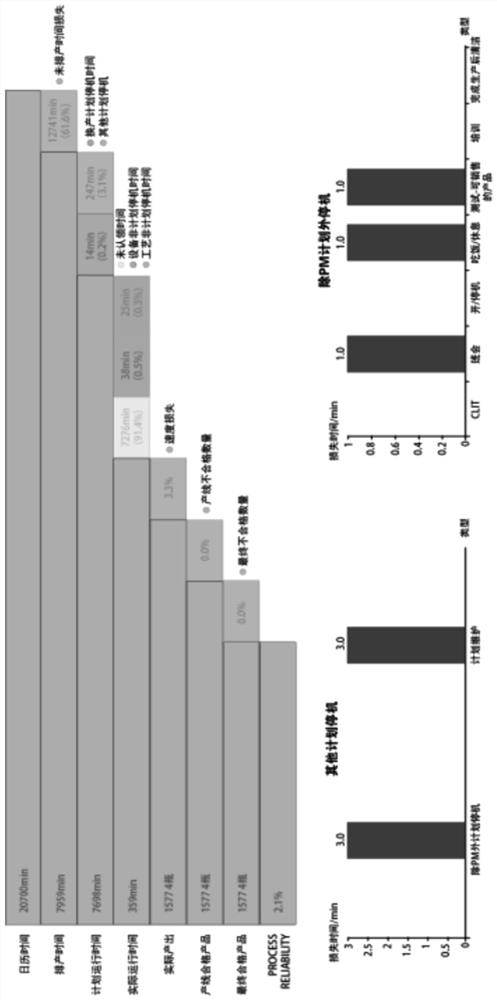

[0075] The OEE and Andon management system of the present invention adopts the cloud mode, the APP is operated online in real time, and the web background is displayed.

[0076] base definition (meaning);

[0077] A = Availability time utilization rate;

[0078] P=Performance performance utilization rate;

[0079] QR=Quality Ratio;

[0080] CT = standard time to produce a part;

[0081] C total = production quantity;

[0082] C combined = qualified quantity;

[0083] T row = scheduling time;

[0084] T work = actual working time;

[0085] T standard = CT * C total production time if the product is converted into production according to the standard takt.

[0086] OEE=A*P*QR

[0087] The time utilization rate is equal to the actual working time divided by the scheduling time.

[0088] The performance utilization rate is expressed as

[0089]

[0090] so

[0091] The above are some basic formulas for OEE calculation,

[0092] Next, when there are multi...

Embodiment 3

[0115] The OEE and Andon management system of the present invention is based on cloud computing deployment, and integrates functions such as kanban display, light control display, and data analysis. Functional modules include:

[0116] 1. System background maintenance module;

[0117] 2. Work order online module;

[0118] 3. Personnel online module;

[0119] 4. Equipment online module;

[0120] 5. Abnormal online (Andon) module;

[0121] 6. Real-time data acquisition module;

[0122] 7. Performance online module;

[0123] 8. Report export module.

[0124] The specific functions of the above modules are as follows:

[0125] 1. System background maintenance: Configure basic information, areas, personnel, shifts, shifts, equipment, types, reports, etc. according to user needs. The functions of the system background maintenance module refer to the following Figure 1-3 , Some basic configurations including areas, personnel, shifts, teams, equipment, types, etc. can be config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com